Method for dissolving epoxy resin

An epoxy resin, complete dissolving technology, applied in the chemical industry, can solve the problems of long dissolution, heating and dispersion, high solvent toxicity, etc., and achieve the effects of short time consumption, wide applicability and low energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] Dissolve the macromolecular epoxy resin (NPES-907 of Taiwan Nanya Company) in the mixed solvent of aromatic hydrocarbon and propylene glycol ether, and use the reflux stirring method of the reactor to dissolve it completely, then cool it, and set up six groups of experiments. See Table 1-1 for specific process conditions.

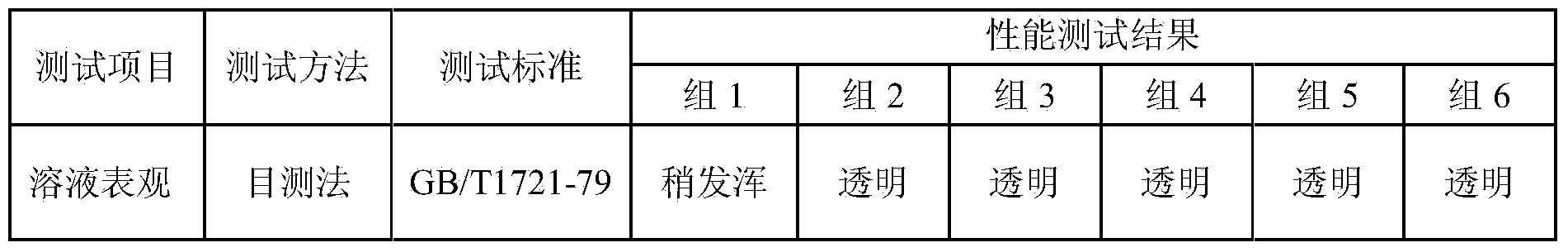

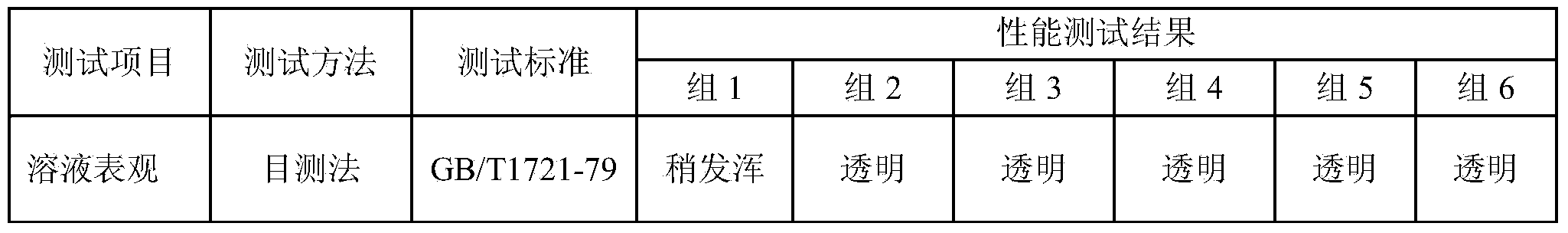

[0020] Table 1-1 Six groups of experimental dissolution process parameters

[0021] Dissolving process

group 1

group 2

group 3

group 4

Group 5

Group 6

Dissolving temperature / ℃

45

45

50

50

55

55

Reflux dispersion time / min

20

40

20

40

20

40

[0022] Table 1-2 Distribution ratio of each group in six groups of experiments (unit: parts by weight)

[0023] components

group 1

group 2

group 3

group 4

Group 5

Group 6

macromolecular epoxy resin

30

30

45

45

60

60

35

0

20...

Embodiment 2

[0029] Dissolve the macromolecular epoxy resin (DER-669 from Dow, USA) in a mixed solvent of aromatic hydrocarbon and propylene glycol ether, and stir it to dissolve completely by using the reflux stirring method of the reactor, and then cool it down. Six groups of experiments are set up. , see Table 2-1 for specific process conditions.

[0030] Table 2-1 Six groups of experimental dissolution process parameters

[0031] Dissolving process

group 1

group 2

group 3

group 4

Group 5

Group 6

Dissolving temperature / ℃

45

45

50

50

55

55

Reflux dispersion time / min

30

60

30

60

30

60

[0032] Table 2-2 Distribution ratio of each group in six experiments (unit: parts by weight)

[0033] components

group 1

group 2

group 3

group 4

Group 5

Group 6

macromolecular epoxy resin

30

30

45

45

60

60

35

0

20 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com