Method for preparing silicon nanostructured material

A technology of structural materials and silicon nanometers, which is applied in the field of preparing silicon nanostructured materials, can solve the problem of low cost and achieve the effect of low cost and simple and easy method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

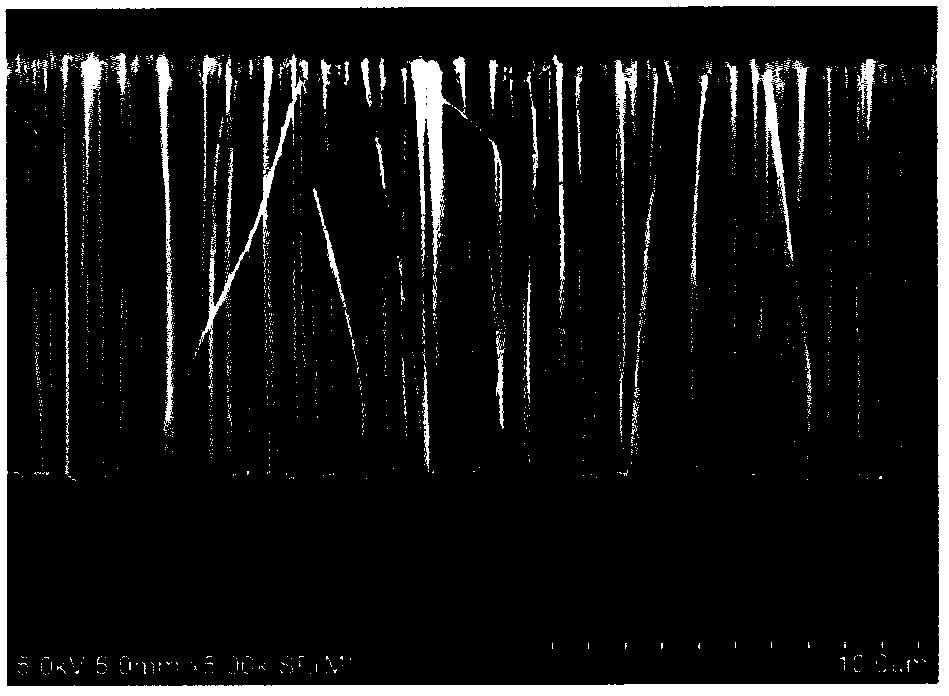

Image

Examples

Embodiment 1

[0012] Put the clean silicon chip into a mixed solution of 5mol / L hydrofluoric acid and 0.25mol / L silver nitrate, and chemically silver-plate the silicon surface at 25 degrees Celsius for 1 minute, then immerse the obtained silicon chip and graphite rod in 2mol / L In the aqueous solution of hydrofluoric acid, the ratio of the area of the graphite rod immersed in the aqueous solution of hydrofluoric acid to the silicon chip is 8:1. The silicon chip and the graphite rod are connected with a wire, and they are corroded at 25 degrees Celsius for 20 minutes to obtain a silicon nanostructure material. .

Embodiment 2

[0014] Put the clean silicon chip into a mixed solution of 5mol / L hydrofluoric acid and 0.25mol / L silver nitrate, and chemically silver-plate the silicon surface at 25 degrees Celsius for 1 minute, then immerse the obtained silicon chip and graphite rod in 5mol / L In the hydrofluoric acid aqueous solution, the ratio of the area of the graphite rod immersed in the hydrofluoric acid aqueous solution to the silicon chip is 8:1, connect the silicon chip and the graphite rod with a wire, and corrode at 25 degrees Celsius for 100 minutes to obtain a silicon nanostructure material .

Embodiment 3

[0016] Put the clean silicon chip into a mixed solution of 10mol / L hydrofluoric acid and 0.25mol / L silver nitrate, and chemically silver-plate the silicon surface at 25 degrees Celsius for 1 minute, then immerse the obtained silicon chip and graphite rod in 5mol / L In the aqueous solution of hydrofluoric acid, the ratio of the area of the graphite rod immersed in the aqueous solution of hydrofluoric acid to the silicon chip is 20:1. The silicon chip and the graphite rod are connected with a wire, and corroded at 25 degrees Celsius for 60 minutes to obtain a silicon nanostructure material. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com