LED lens generating square light spot

A technology of LED lens and square light spot, which is applied in the direction of semiconductor devices, light sources, point light sources, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to understand the technical content of the present invention more clearly, the following examples are given in detail.

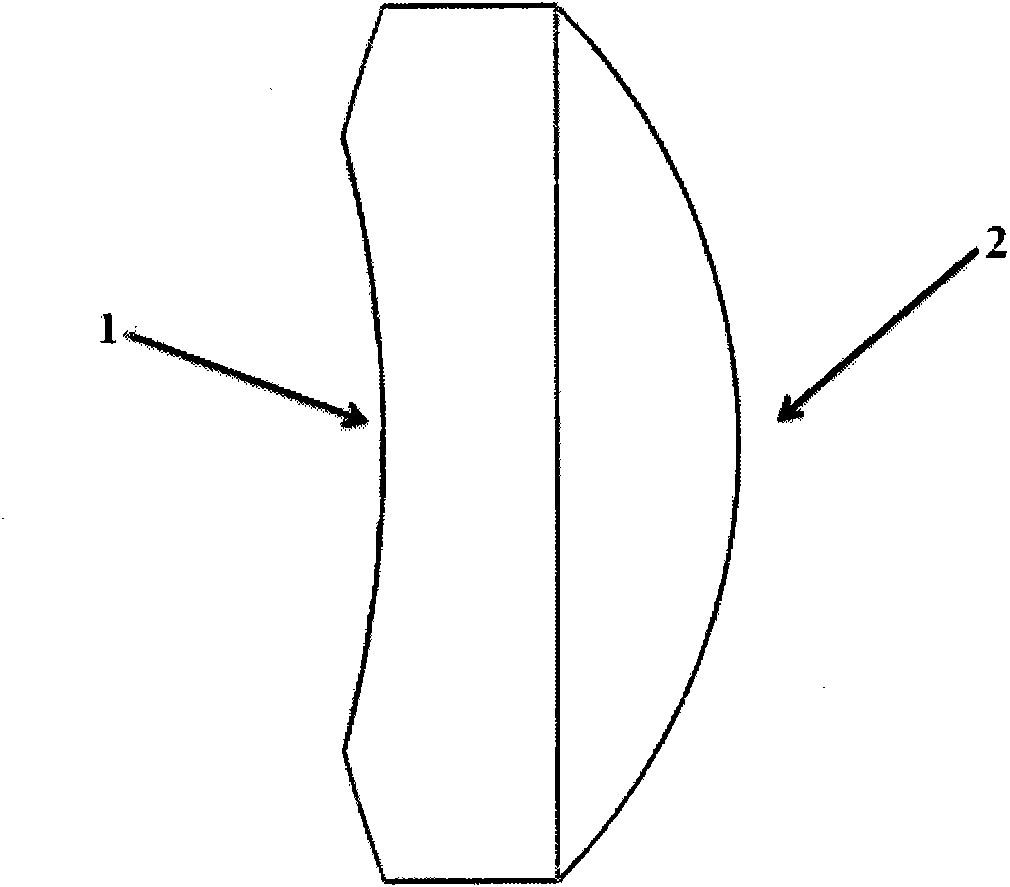

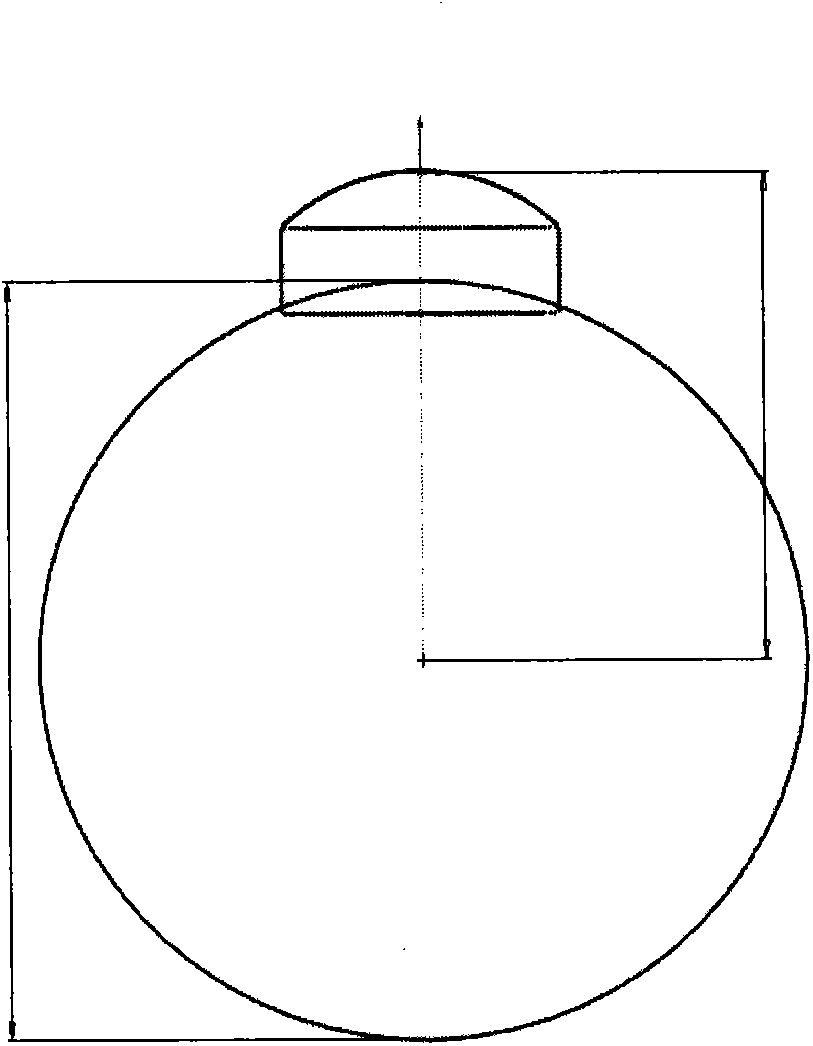

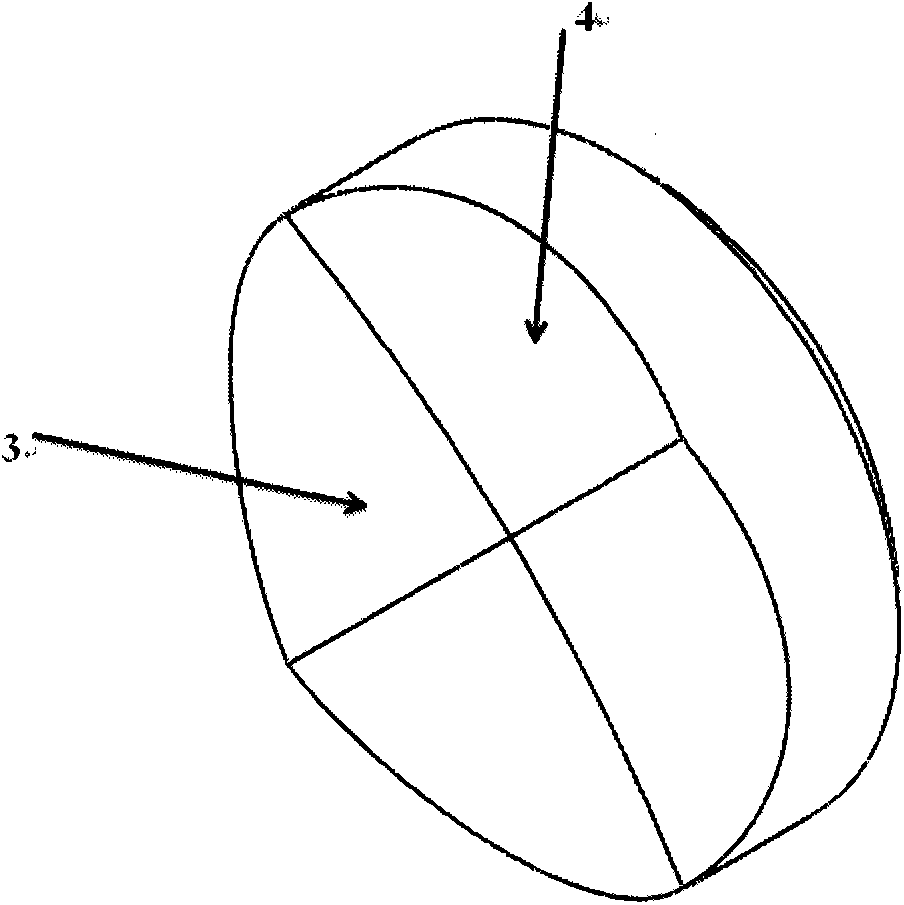

[0024] exist Figure 4 Among them, select an LED point light source chip with package width w, place a hemispherical optical lens with radius r at the front end L1 of the chip, place the lens of the present invention at the position L2 of the lens front end, and place the rear surface along two mutually perpendicular directions The concave part of the cylindrical surface 3, 4 of the radius R11 (see image 3 ), whose front surface is a partial spherical surface 2 with curvature R12 (see figure 1 ), the total thickness of the lens is T1, and the illuminated surface is placed at the front end L3 of the LED lens of the present invention, such as a light screen, and the received light spot is as Figure 5 As shown, the light spot is a square light spot with a side length of about X.

[0025] Will Figure 4 In the lens of the present invention,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com