Novel Fabry-Perot interference MEMS (Micro Electro Mechanical System) sound wave sensor

An acoustic wave sensor and interference type technology, which is applied in the field of microphones, can solve the problems of low sensitivity, poor anti-electromagnetic interference ability, unstable output optical signal, etc., and achieve the effect of high sensitivity and strong anti-interference ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

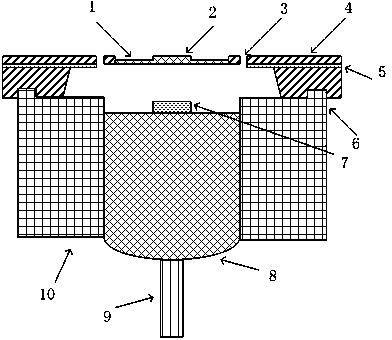

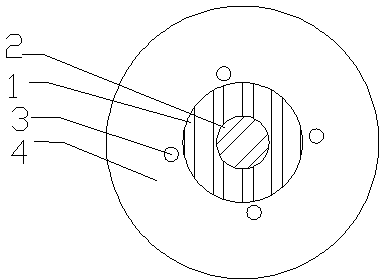

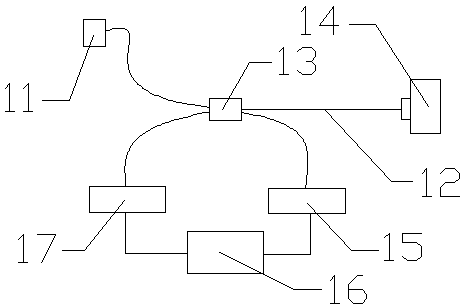

[0019] like figure 1 As shown, a novel Fabry-Perot interferometric MEMS acoustic wave sensor includes a collimator, an SOI wafer and a bushing arranged under the SOI wafer for supporting the SOI wafer and fixing the collimator, because the collimator, etc. All are cylindrical, so the sleeve is an annular sleeve 10. The annular sleeve 10 provides support for the SOI wafer substrate, and the two are bonded together by ultraviolet glue, wherein the central axis of the annular sleeve 10 coincides with the center normal of the circular silicon film on the SOI wafer, and the annular The diameter of the ferrule 10 is larger than the diameter of the fiber collimator. An acoustically sensitive film 1 is formed on the SOI wafer through photolithography, corrosion, and oxidation. The center of the acoustically sensitive film 1 is provided with a circular boss 2. The thickness of the circular boss 2 is equal to the thickness of the acoustically sensitive film 1, and the diameter is not l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com