Vertical multi-plate wave maker

A wave maker and vertical technology, applied in the field of hydrodynamic experiment research, can solve problems such as boundary input nonlinear vertical velocity distribution, achieve enhanced operational flexibility and stability, reduce maintenance and maintenance costs, reduce The effect of length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

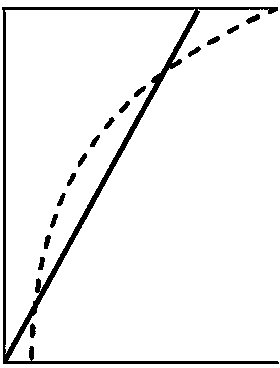

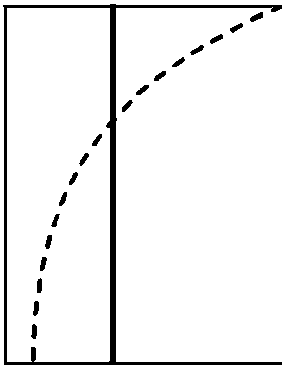

Problems solved by technology

Method used

Image

Examples

Embodiment 1

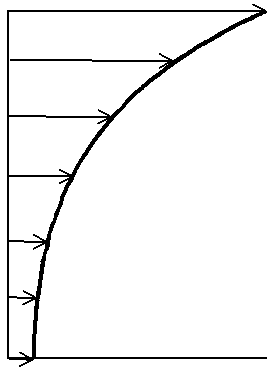

[0031] Such as Figure 4 As shown in -7, the vertical multi-plate wave maker includes a water tank 3, a hydraulic station 2 installed on the water tank 3, a computer control system 6 for generating nonlinear wave control signals, a support 7, and a support 7 The actuator 4 connected, the wave-making plate 1 hinged with the actuator 4, the computer control system 6 is connected with the hydraulic station 2 and the servo valve, the hydraulic station 2 is connected with the actuator, and the actuator 4 is used to drive the wave-making plate 1 to reciprocate Movement, the wave-making plate 1 is formed by hinged joints of multiple independent wave-making plates.

[0032] In this embodiment, the computer control system 6 is used to generate a nonlinear wave control signal, which is sent to the hydraulic station 2 and the servo valve, and the servo valve controls the actuator 4 to generate power, and the actuator 4 drives the wave-making plate 1 to reciprocate. Since the wave-making...

Embodiment 2

[0041] Such as Figure 8 , 9 Among them, the actuator 4 includes a first actuator 41, a second actuator 42, a third actuator 43, and a fourth actuator 44 arranged from top to bottom; the first actuator 41 is connected to the bracket through the first hinge point 71 of the bracket Hinged, the second actuator 42 is hinged to the bracket through the second hinge point 72 of the bracket, the third actuator 43 is rigidly connected to the bracket through the rigid node 74, and the fourth actuator 44 is rigidly connected to the bracket through the rigid node 75. . The first actuator 41 is provided with a first push rod 411, and the first push rod 411 is hinged to the middle of the first wave-making plate 11 through the first push rod hinge point 411A; the second actuator 42 is provided with a second push rod 421, the second push rod 421 is hinged to the middle of the second wave-making plate 12 through the second push rod hinge point 421A; the third actuator 43 is provided with a t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com