Multifunctional double-channel welding line ultrasonic testing scanner

A dual-channel, ultrasonic technology, used in the analysis of solids using sonic/ultrasonic/infrasonic waves, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problem of small up and down displacement of the probe holder, unsuitable, unsuitable for large-scale curvature adjustment and other problems, to achieve the effect of small transverse magnetic wheel spacing and improved work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

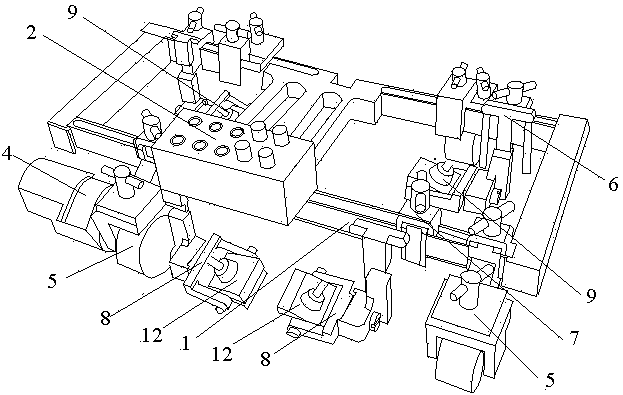

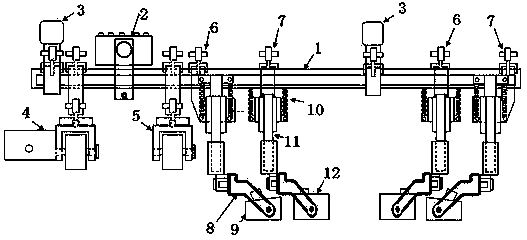

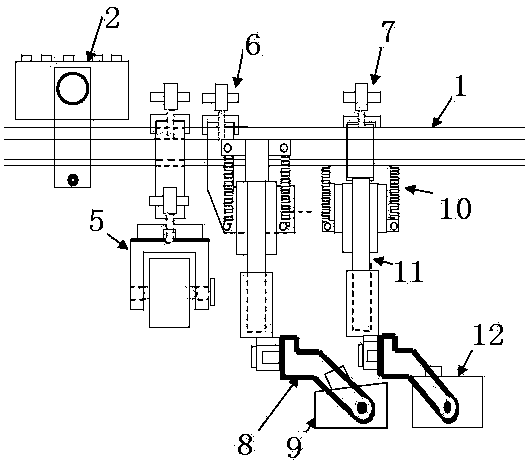

[0071] Such as Figure 2-Figure 15 As shown, the multifunctional dual-channel weld seam ultrasonic detection scanner of this patent includes an integral sliding main support rod 1, a filter and a junction box, a handle, a digital encoder and a magnetic wheel set 5, and two sets of corresponding TOFD probes system, two sets of corresponding creeping wave probe support systems;

[0072] Among them, the sliding main support rod 1 is a long rod with a sliding groove in the middle; it has the functions of fixing a filter, an encoder, a magnetic wheel set, and a probe support frame;

[0073] The magnetic wheel set 5 is fixed on one end of the sliding main support rod 1 (to detect the welding joint with an elbow) or both ends (to detect the butt weld joint of the straight pipe); the digital encoder is fixed on the magnetic wheel set 5 or on the TOFD probe; The handle is fixed on one or both ends of the sliding main support rod 1;

[0074] The magnetic wheel set 5 includes a top fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com