A thermionic device and its manufacturing method

A thermionic and device technology, applied in electric solid state devices, semiconductor devices, semiconductor/solid state device components, etc., can solve the problems of limiting photovoltaic and thermoelectric conversion efficiency, high product cost, and poor thermal insulation, etc. Simple structure, lower production cost, stable and reliable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

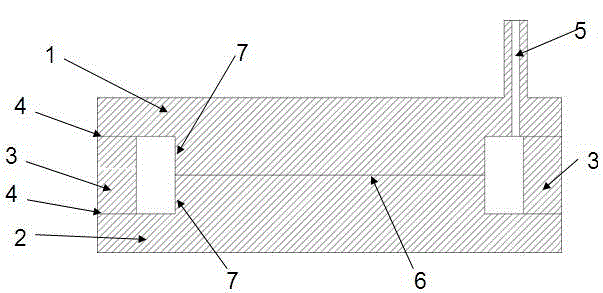

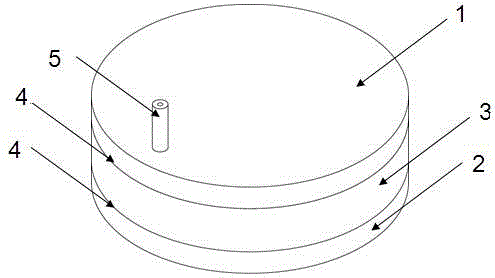

[0015] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment: as figure 1 with figure 2 As shown, 1 is the thermion emitter plate, 2 is the thermion receiving plate, 3 is the control ring, 4 is the thermal insulation sealing layer, 5 is the process hole; 6, the gap; 7, the protruding part.

[0016] In this embodiment, the thermionic emitter plate 1 and thermionic receive plate 2 are made of red copper, the control ring is made of an aluminum alloy ring material, and the thermal insulation sealing layer is made of epoxy resin sealing material as an example to explain the thermionic device. How to make and use it. First put the aluminum alloy control ring 3 in the middle of thermion emitter plate 1 and thermion receiver plate 2, the thickness of the aluminum alloy control ring 3 is slightly smaller than the protruding part of thermion emitter plate 1 and thermion receiver plate 2 The sum of the heights of 7, the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com