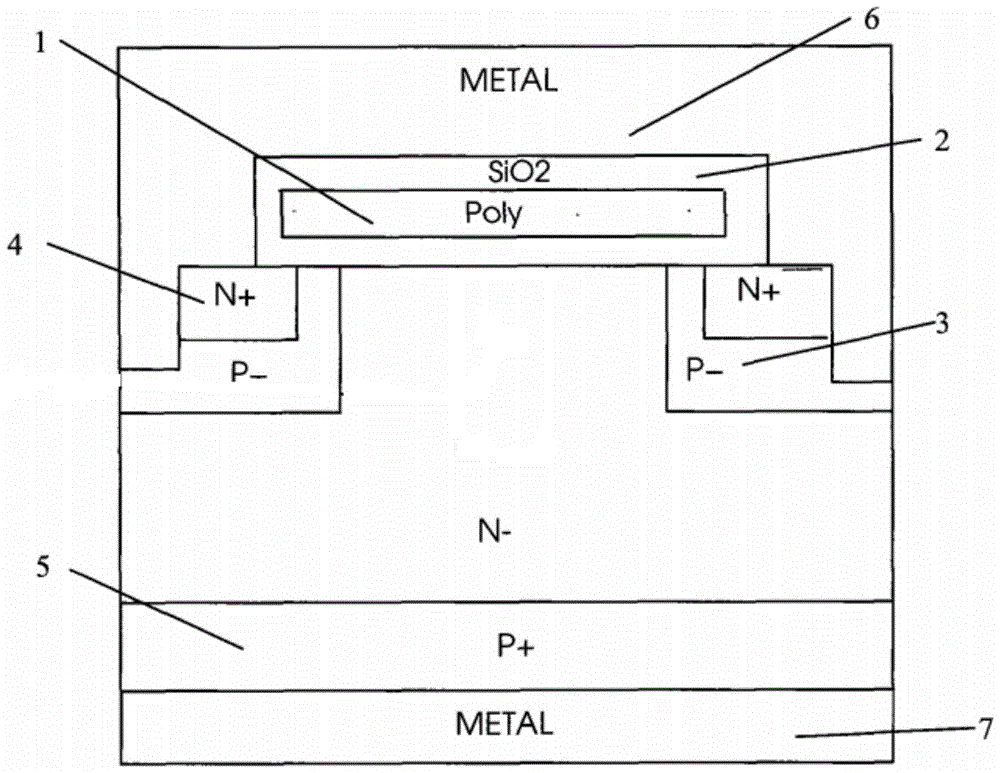

An igbt chip based on n-type injection layer and its manufacturing method

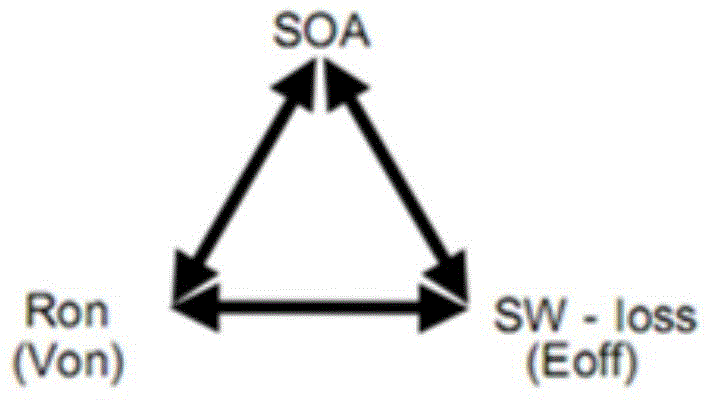

A manufacturing method and injection layer technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of large chip terminal area size, large conduction loss, large saturation voltage, etc., achieve process compatibility, improve current ability, the effect of reducing the saturation voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Embodiment 1 of the manufacturing method of IGBT active region structure of the present invention see Figure 5 . Figure 5 Among them, the N-type injection layer 9 surrounds the P-base region 3, function 1, the horizontal and vertical dimensions of the P-base region are compressed, the distance between the P-base regions increases, the excess carrier concentration increases, and the saturation voltage decreases. Function 2, the channel length becomes shorter, the channel resistance becomes smaller, and the saturation voltage decreases. Function 3, the radius of curvature at the corner of the P-base region decreases, the breakdown voltage decreases, and there is a risk of breakdown. Among them, functions 1 and 2 are advantages, and function 3 is a disadvantage, which needs to be considered in compromise.

Embodiment 2

[0055] Example 2 of the manufacturing method of the IGBT active region structure of the present invention see Figure 6 . Figure 6 Among them, the N-type injection layer 9 surrounds the P-base region 3 and extends below the gate oxide layer 8 . Effect 1, compared with Example 1, the excess carrier field further increases, and the saturation voltage further decreases. Function 2, the channel length becomes shorter, the channel resistance becomes smaller, and the saturation voltage decreases. Function 3, the radius of curvature at the corner of the P-base region decreases, the breakdown voltage decreases, and there is a risk of breakdown. Effect 4, compared with Example 1, the number of N-type injection layer photolithography plates can be reduced, and the cost can be reduced. Among them, functions 1, 2, and 4 are advantages, and function 3 is a disadvantage, which needs to be considered in compromise. Implementation example 2 further enhances the current capability of the ...

Embodiment 3

[0057] Example 3 of the manufacturing method of the IGBT active region structure of the present invention see Figure 7 . Figure 7 In this example, compared with Embodiment 1, the N-type injection layer 9 surrounds the P-base region 3 and does not surround the corner of the P-base region. Advantages 1, 2 of embodiment 1 are therefore inherited, while disadvantage 3 of embodiment 1, namely the risk of breakdown, is avoided.

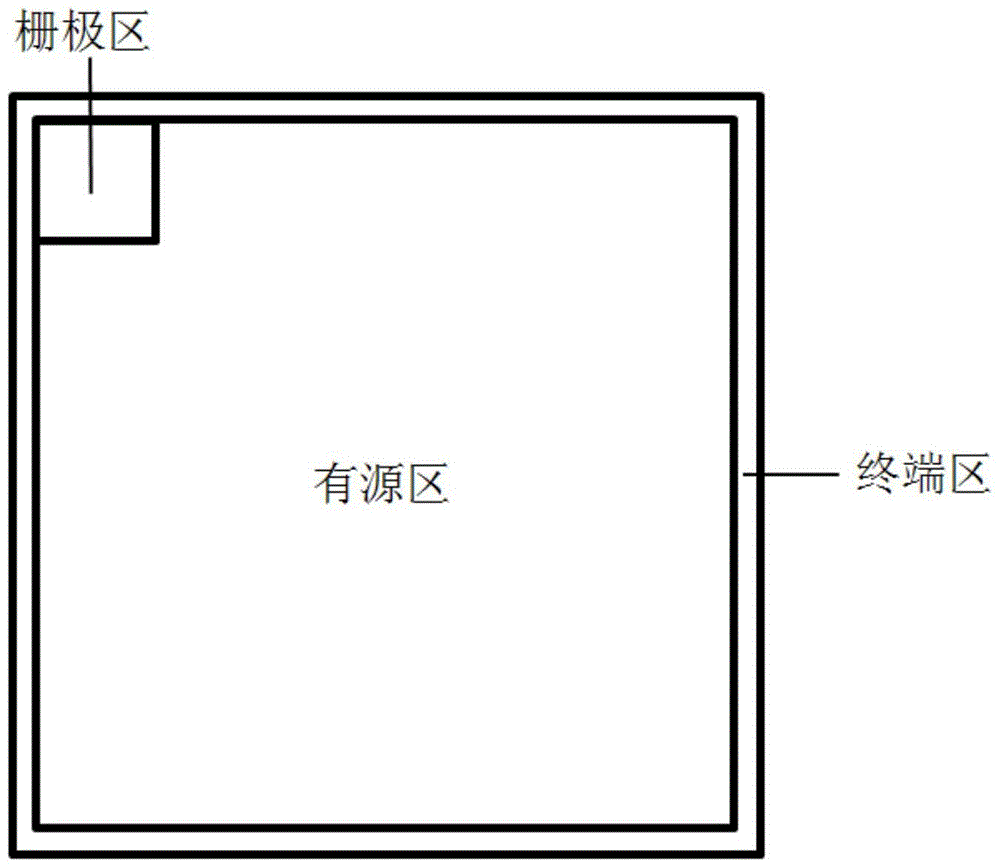

[0058] The terminal area is located in the edge area of the IGBT chip and integrates the withstand voltage parameters of the IGBT chip. The terminal area includes a terminal basic unit; the terminal basic unit includes a field plate, a field limiting ring, a junction terminal extension protection module, a lateral variable doping Miscellaneous modules and resistive field plates, the terminal basic unit is used to reduce the curvature of the PN junction at the edge of the active region, the depletion layer extends laterally, and enhances the withstand v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com