Method for manufacturing grain insect expelling bags

A technology of insect repellent bags and food, applied in animal repellent, application, animal husbandry, etc., can solve problems such as physical and mental health hazards, excessive pesticide residues, fatal dangers, etc., and achieve simple production principles, simple design principles, and non-toxic side effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

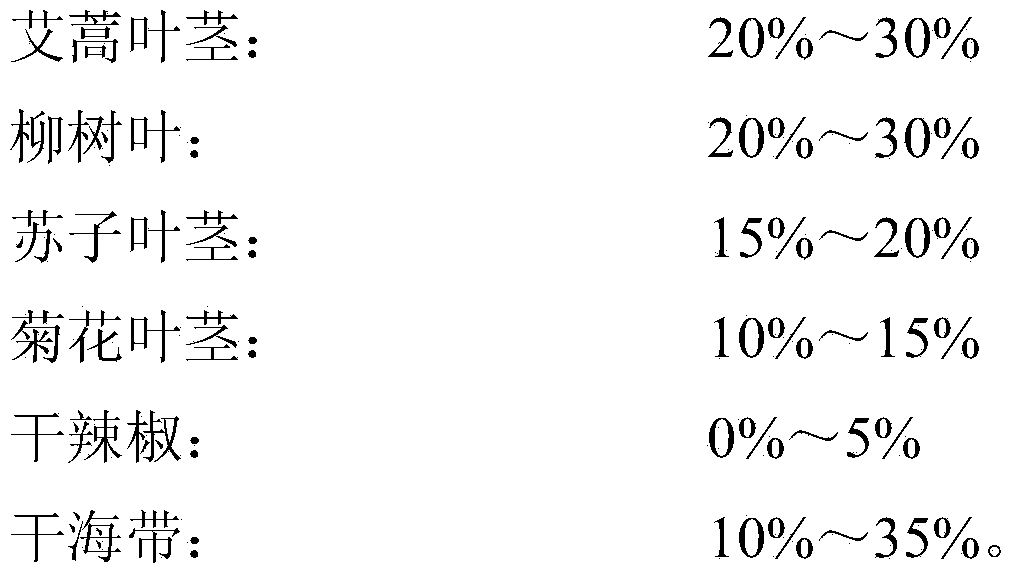

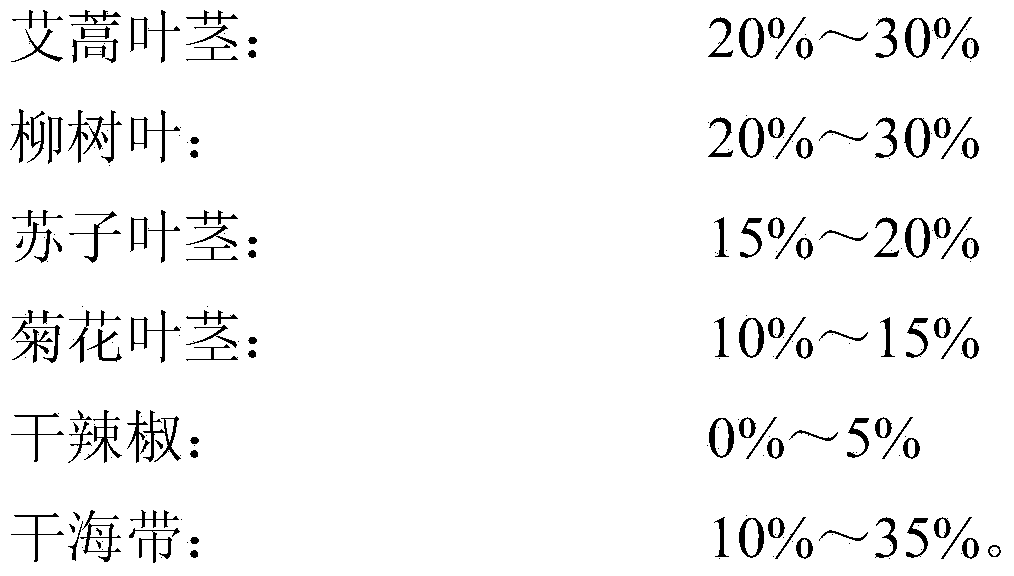

[0015] The main raw materials in this example include mugwort leaf stems, willow leaves, perilla leaf stems, chrysanthemum leaf stems, dried kelp and dried peppers. The main process includes four steps: batching, crushing and stirring, bag making and packaging:

[0016] (1) Ingredients: first weigh 20% of dried mugwort leaves, 20% of willow leaves, 15% of perilla leaves, 10% of chrysanthemum leaves and ~35% of dried kelp according to weight percentage, and then separate the raw materials of each plant into Cut into shapes with a geometric size of 1-5mm, mix them evenly, and dry them in a dryer until the moisture content is lower than 12.5% to obtain a plant mixture;

[0017] (2) Crushing and stirring: put the dried plant mixture into a pulverizer and pulverize it into a powder with a particle size of less than 1mm, put it in a container and stir and mix in the same direction to obtain a plant mixed powder;

[0018] (3) Bag making: Take dried Zanthoxylum bungeanum according t...

Embodiment 2

[0021] The main raw materials in this example include mugwort leaf stems, willow leaves, perilla leaf stems, chrysanthemum leaf stems, dried kelp and dried peppers. The main process includes four steps: batching, crushing and stirring, bag making and packaging:

[0022] (1) Ingredients: First weigh 30% of dried mugwort leaf stems, 30% of willow leaves, 15% of perilla leaf stems, 10% of chrysanthemum leaf stems, 5% of dried peppers and 10% of dried kelp according to weight percentage, and then Each plant raw material is cut into a shape with a geometric size of 1-5mm, mixed evenly, and then dried in a dryer until the moisture content is less than 12.5% to obtain a plant mixture;

[0023] (2) Crushing and stirring: put the dried plant mixture into a pulverizer and pulverize it into a powder with a particle size of less than 1mm, put it in a container and stir and mix in the same direction to obtain a plant mixed powder;

[0024] (3) Bag making: Take dried Zanthoxylum bungeanum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com