Insect-proof heat-insulating fabric and preparation method thereof

A fabric and insect-proof technology, applied in the textile field, can solve problems such as non-insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

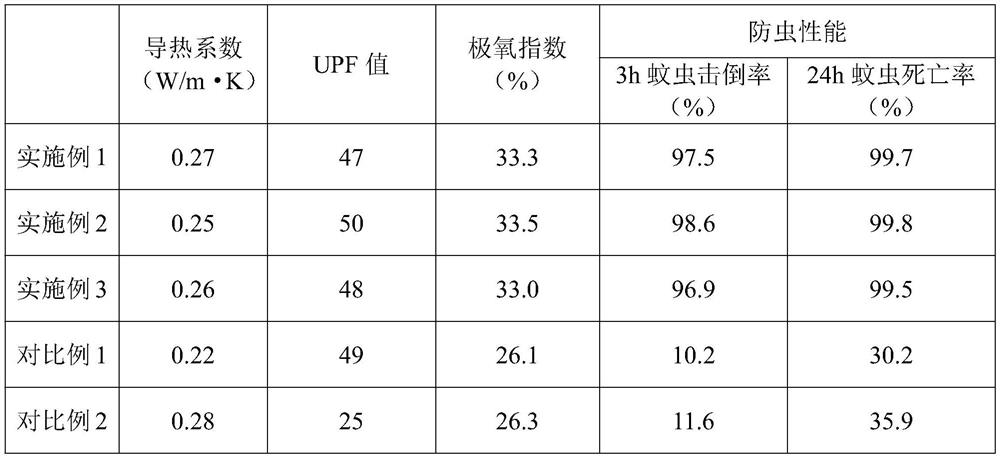

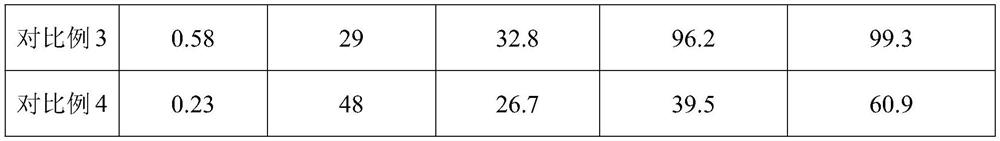

Examples

Embodiment 1

[0031] A preparation method of an insect-proof and heat-insulating fabric, the preparation method of the insect-proof heat-insulating fabric comprises the following preparation steps:

[0032] (1) At room temperature and under argon protection, mix 2-chloropropenone and o-hydroxybutenone in a mass ratio of 1:1.2, stir at 500 r / min for 10 min, and then add 0.01 times the mass of 2-chloropropenone. Aluminum trichloride was cooled to 1°C at 3°C / min, and stirred for 6 hours to prepare 3-hydroxy-5-aminopropenyl phenbutene; under the conditions of 60°C and 2MPa, polytetrafluoroethylene with a molecular weight of 1600 was prepared. Ethylene fluoride and 3-hydroxy-5-aminopropenyl phenbutene were mixed in a mass ratio of 1:0.3, stirred at 500 r / min for 30 min, and then added dropwise at 40 drops / min of diphenyl peroxide with a mass of 0.1 times the mass of polytetrafluoroethylene Formyl was stirred at 900 r / min for 2 h, cooled to room temperature at 3 °C / min, filtered, washed twice wit...

Embodiment 2

[0038] A preparation method of an insect-proof and heat-insulating fabric, the preparation method of the insect-proof heat-insulating fabric comprises the following preparation steps:

[0039] (1) At room temperature and under argon protection, mix 2-chloropropenamine and o-hydroxybutenone in a mass ratio of 1:1.3, stir at 600 r / min for 15 min, and then add 0.02 times the mass of 2-chloropropenamine. Aluminum trichloride was cooled to 3°C at 4°C / min, and continued to stir for 7 h to prepare 3-hydroxy-5-aminopropenyl phenbutenone; under the conditions of 70°C and 3MPa, polytetrafluoroethylene with a molecular weight of 1800 was prepared. Ethylene fluoride and 3-hydroxy-5-aminopropenyl phenbutene were mixed at a mass ratio of 1:0.4, stirred at 600 r / min for 40 min, and then added dropwise with 0.2 times the mass of PTFE diphenyl peroxide at 50 drops / min Formyl was stirred at 1000r / min for 3h, cooled to room temperature at 4°C / min, filtered, washed three times with absolute ethan...

Embodiment 3

[0045] A preparation method of an insect-proof and heat-insulating fabric, the preparation method of the insect-proof heat-insulating fabric comprises the following preparation steps:

[0046] (1) At room temperature and under argon protection, mix 2-chloropropenamine and o-hydroxybutenone in a mass ratio of 1:1.4, stir at 700 r / min for 20 min, and then add 0.03 times the mass of 2-chloropropenamine. Aluminum trichloride was cooled down to 5°C at 5°C / min, and stirred for 8 hours to prepare 3-hydroxy-5-aminopropenyl ketene; under the conditions of 80°C and 4MPa, polytetrafluoroethylene with a molecular weight of 2000 was prepared. Ethylene fluoride and 3-hydroxy-5-aminopropenyl phenbutene were mixed at a mass ratio of 1:0.5, stirred at 700 r / min for 50 min, and then added dropwise at 60 drops / min of diphenyl peroxide with a mass of 0.3 times the mass of polytetrafluoroethylene Formyl was stirred at 1100r / min for 4h, cooled to room temperature at 5°C / min, filtered, washed 4 time...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com