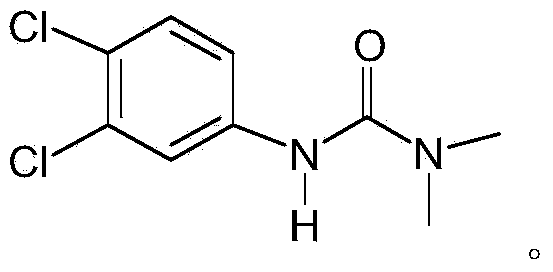

Method for preparing diuron

A technology of diuron and xylene, which is applied in the field of preparation of diuron, can solve the problems of low content, low product yield, difficult separation and purification, etc., to reduce the generation of by-products, benefit environmental protection, and save costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

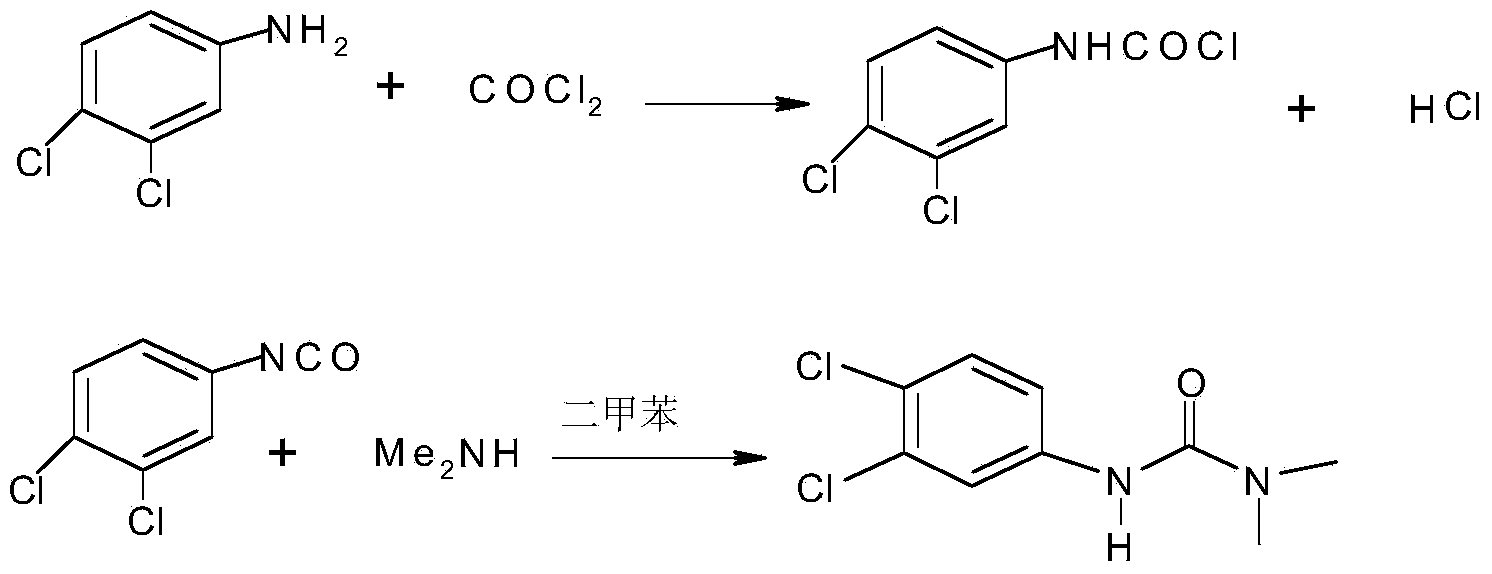

Method used

Image

Examples

Embodiment 1

[0024] In a 500L dissolution kettle, add 150 kg of xylene and 60 kg of 3,4-dichloroaniline, stir, open the steam valve, slowly raise the temperature to 55°C, and stir for 1 hour. After the 3,4-dichloroaniline is completely dissolved, Drive it into the high gauge slot. In a 500L reaction kettle, add 230 kg of xylene, lower the temperature, pass 12 kg of phosgene, and when the temperature drops to -2°C, add the xylene solution of the above-mentioned 3,4-dichloroaniline dropwise, after 2 hours, stir React for 3-4 hours and raise the temperature to 130°C, then add phosgene until the material is clear and transparent, stop passing phosgene, and use N 2 Catch phosgene and rectify to obtain 68.6 kg of pure 3,4-dichlorophenylisocyanate with a purity of 98.7%.

[0025] In a 500L dissolution kettle, add 250 kg of xylene, add 68.6 kg of 3,4-dichlorophenyl isocyanate prepared above, raise the temperature to 60°C, stir for 1 hour, pass in 18.10 kg of dimethylamine gas, and stir After 2 h...

Embodiment 2

[0027] The preparation of 3,4-dichlorophenylisocyanate is the same as in Example 1.

[0028] In a 500L dissolution kettle, add 220 kg of toluene, add 68.6 kg of 3,4-dichlorophenyl isocyanate prepared above, raise the temperature to 60°C, stir for 1 hour, and introduce 18.10 kg of dimethylamine gas, and stir for 2 hours , when the content of 3,4-dichlorophenylisocyanate is below 0.1wt% of the whole reaction system, the reaction is terminated, filtered by suction, and dried to obtain 82.65 kg of diuron solid, with a content of 99.3% and a yield of 94.8%.

Embodiment 3

[0030] The preparation of 3,4-dichlorophenylisocyanate is the same as in Example 1.

[0031] In a 500L dissolution kettle, add 260 kg of o-dichlorobenzene, add 68.6 kg of 3,4-dichlorophenyl isocyanate prepared above, raise the temperature to 60°C, stir for 1 hour, and feed 18.10 kg of dimethylamine gas , stirred for 2 hours, and ended the reaction when the content of 3,4-dichlorophenylisocyanate was below 0.1wt% of the entire reaction system, suction filtered, and dried to obtain 82.72 kg of diuron solids, a content of 99.2%, and a yield of 94.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com