Tunneling method and tunneling machine

A technology for tunnel excavation and roadheader, which is applied to tunnels, earth-moving drilling, mining equipment, etc., can solve the problems of complex manufacturing process, high engineering cost and high cost, and achieve simple manufacturing process, fast excavation speed and light equipment weight. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be described in detail below in conjunction with the accompanying drawings.

[0037] 1. Embodiment of tunneling method:

[0038] Including the following steps:

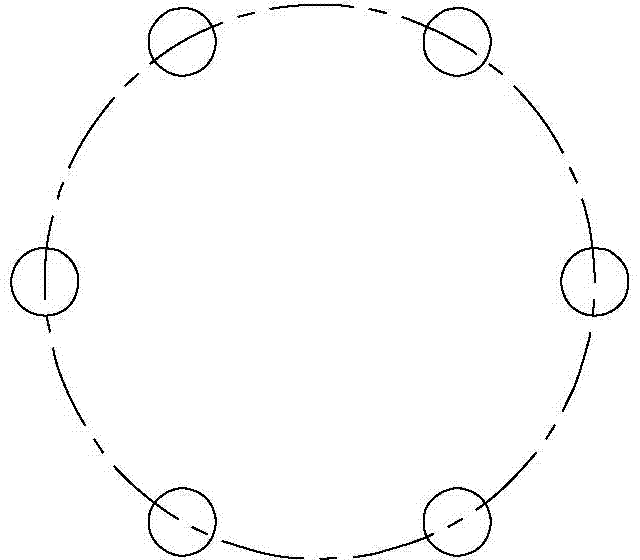

[0039] a) if figure 1 As shown in , multiple holes are drilled simultaneously on the excavation surface where tunneling is to be carried out, and each hole is evenly distributed in the same circle;

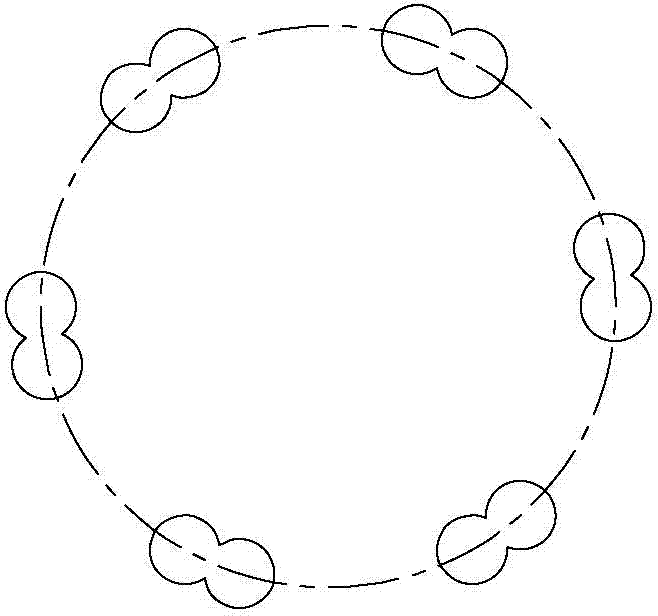

[0040] b) Continue to drill multiple holes tangent to or intersecting the previous hole along its distribution circumference beside the drilled hole, such as figure 2 shown;

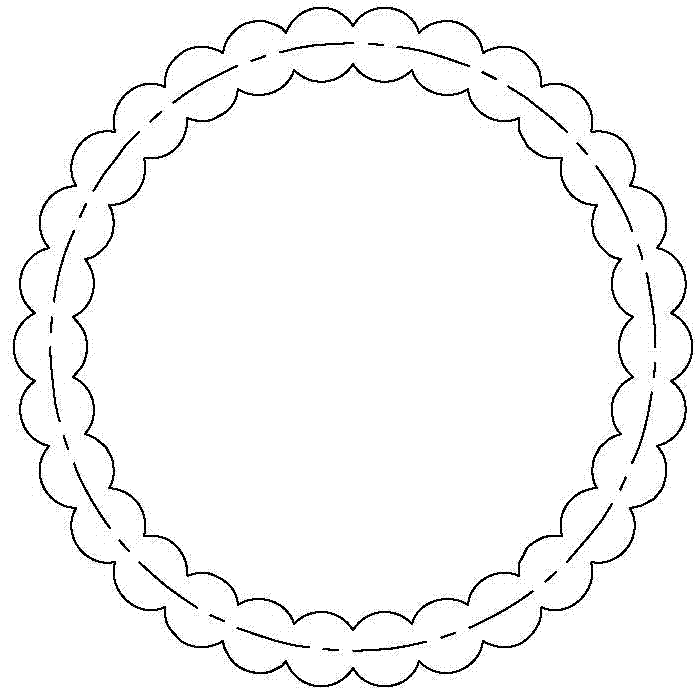

[0041] c) Repeat the above steps until the above-mentioned holes cover the entire hole distribution circle, and form a rock-soil core in the middle of the hole distribution circle, such as image 3 shown.

[0042] d) Fragmenting the rock core, taking out the gravel, and completing a tunneling;

[0043] e) On the excavation surface at the innermost end of the excavated tunnel, repeat the above a) to d) along t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com