Continuous high-temperature nitriding furnace

A technology of high-temperature nitriding and furnace shell, which is applied in the direction of furnace, furnace type, ceramic material production, etc., can solve the problems that the nitriding atmosphere cannot be adjusted in a large range, the space utilization rate is low, and the oxygen can not be driven out, so as to improve the working environment , the degree of automation is improved, and the effect is obvious

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

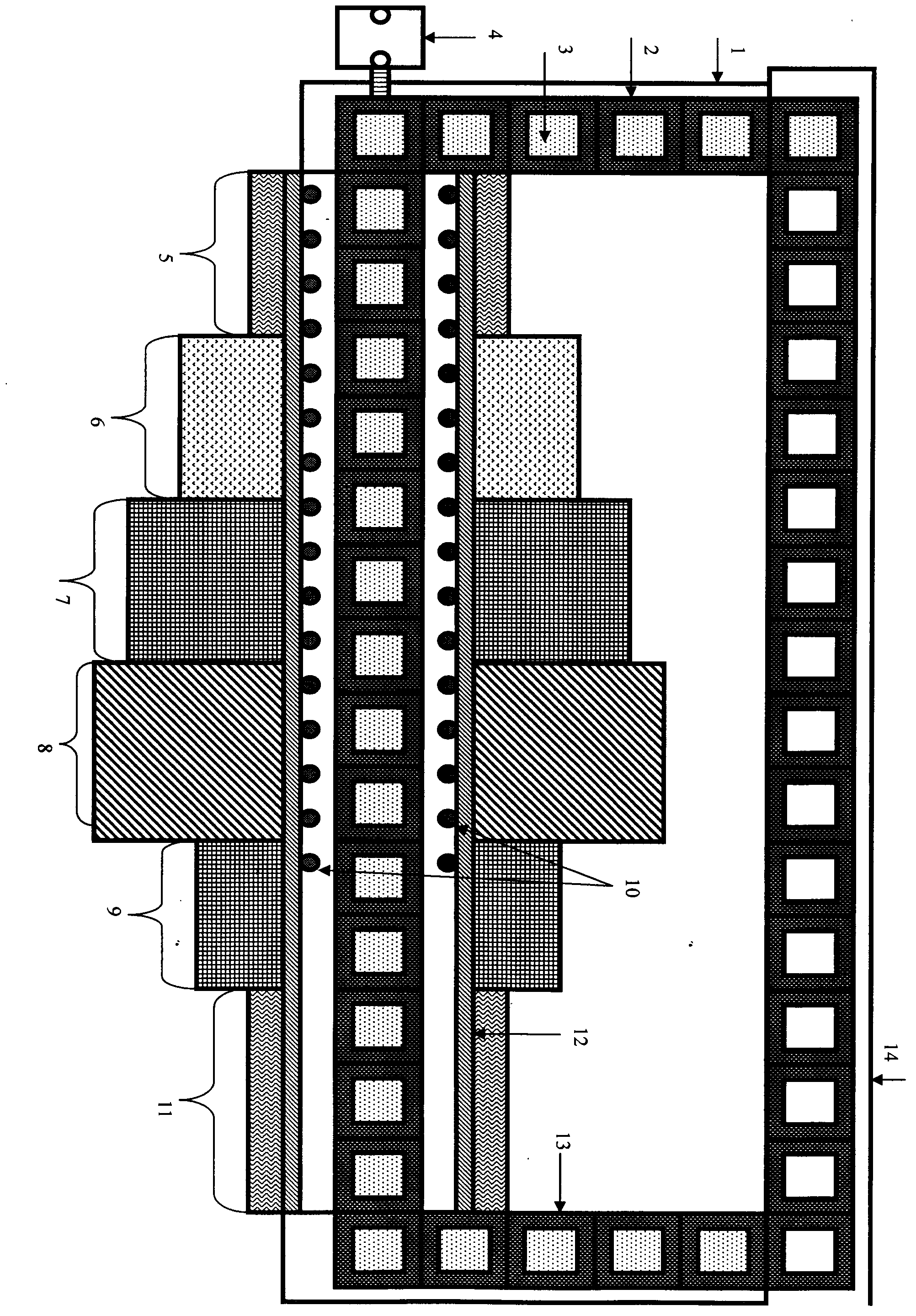

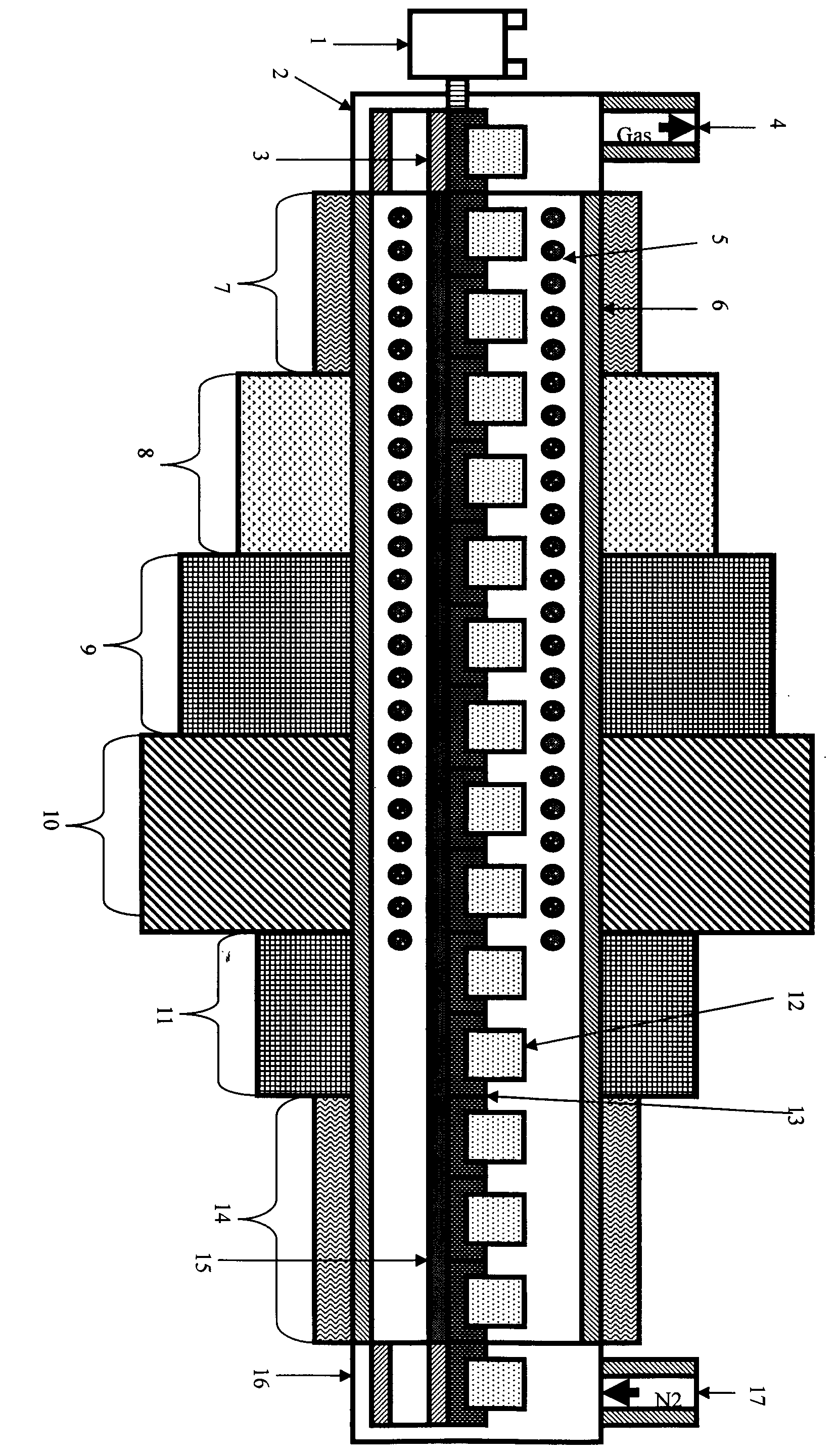

[0017] See figure 1 The nitriding furnace of the present invention includes a furnace shell that can withstand a pressure greater than 0.3 MPa and has different shapes and sizes in the longitudinal direction. Both ends of the furnace shell are open or open for the sagger and the target to be burned to be pushed in and out. The outside is the ramp for entering and exiting the furnace. The ramp is a horizontally installed channel with a sealed enclosure. A sliding table or conveyor belt is installed inside. The door is opened at the end of the furnace body. This door can be closed quickly and can ensure vacuum and pressure. Has reliable sealing performance. Different sections of the furnace shell are built with different insulation materials and refractory linings, leaving a long cavity in the middle. In the lower part of the cavity, a material with high temperature resistance, low friction, abrasion resistance and controlled atmosphere corrosion resistance is installed as a slid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com