A method and system for X-ray detection of defects in a multilayer packaging substrate

A detection method and packaging substrate technology, which is applied in the use of radiation for material analysis, etc., can solve the problems of lead wires affecting the reliability of MCM, weak connections, and affecting the wide application of MCM, and achieve the effects of accurate positioning, improved efficiency, and convenient detection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

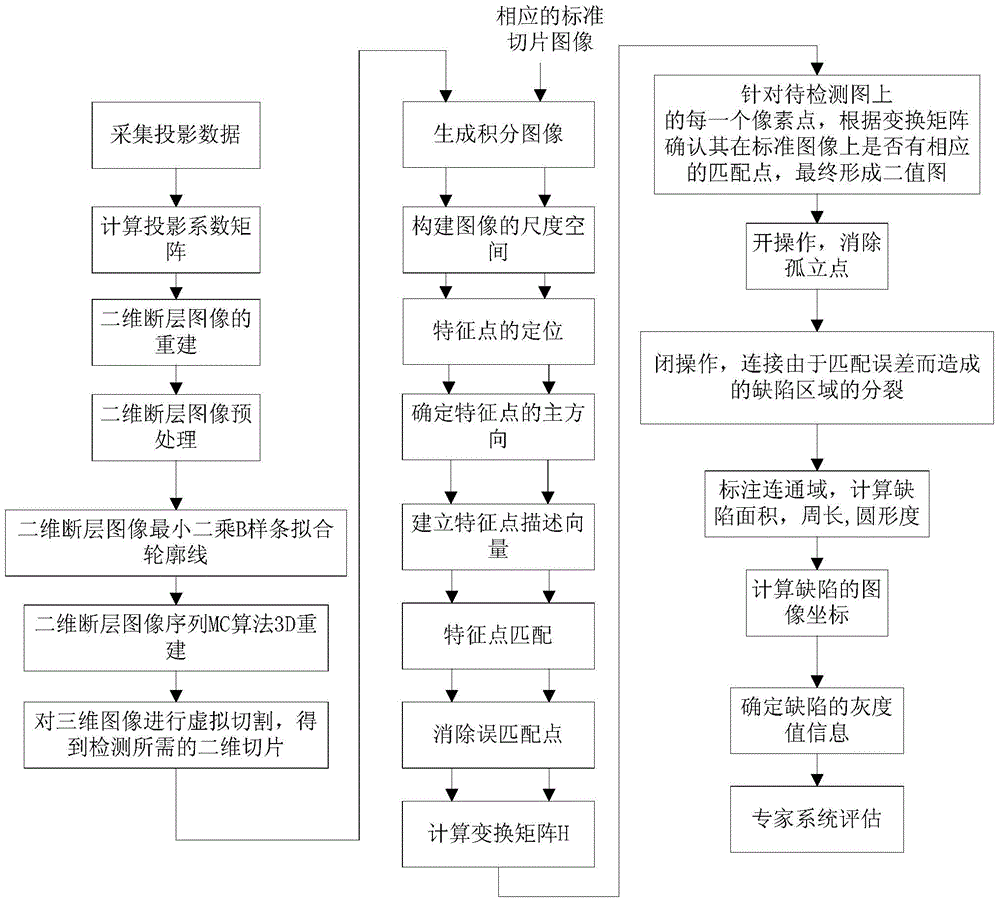

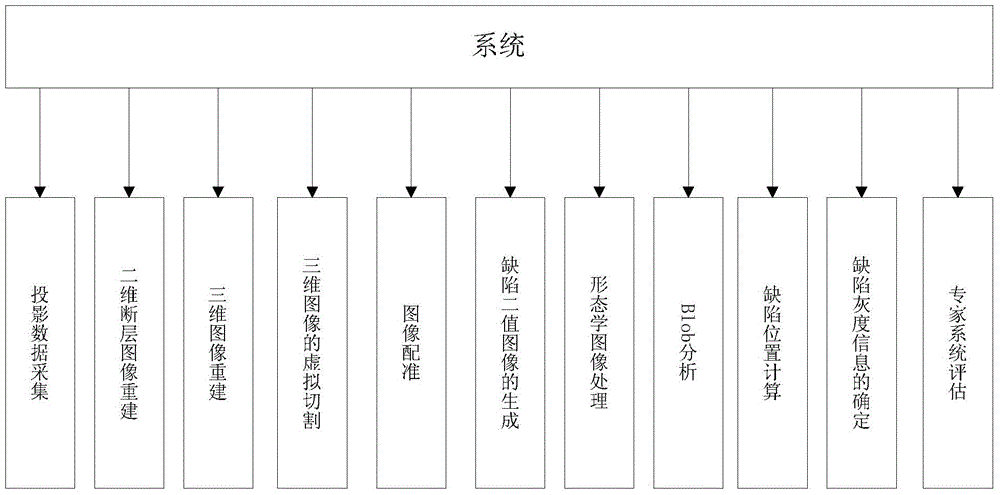

[0062] Such as figure 1 Shown: a kind of X-ray 3D inspection method for multi-layer package substrate defect described in the present invention comprises the following steps:

[0063] (1) Acquisition of projection data;

[0064] (2) Reconstruction of two-dimensional tomographic images;

[0065] (2-1) Calculation of projection coefficient matrix;

[0066] (2-2) Transform the solution problem of two-dimensional tomographic images into a limited optimization problem;

[0067] (2-3) Apply the ART-TV method to solve the above-mentioned limited optimization problem;

[0068] (3) Reconstruction of three-dimensional images;

[0069] (3-1) Read two-dimensional X-ray CT tomographic image sequence;

[0070] (3-2) Two-dimensional tomographic image preprocessing;

[0071] (3-3) Two-dimensional tomographic image least squares B-spline fitting contour line;

[0072] (3-4) 3D reconstruction of two-dimensional tomographic image sequence MC algorithm.

[0073] (4) Virtually cut the obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com