Thin film transistor and producing method

A technology of thin film transistor and manufacturing method, which is applied in the direction of transistor, semiconductor/solid-state device manufacturing, semiconductor device, etc., can solve the problems of component failure and leakage current, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

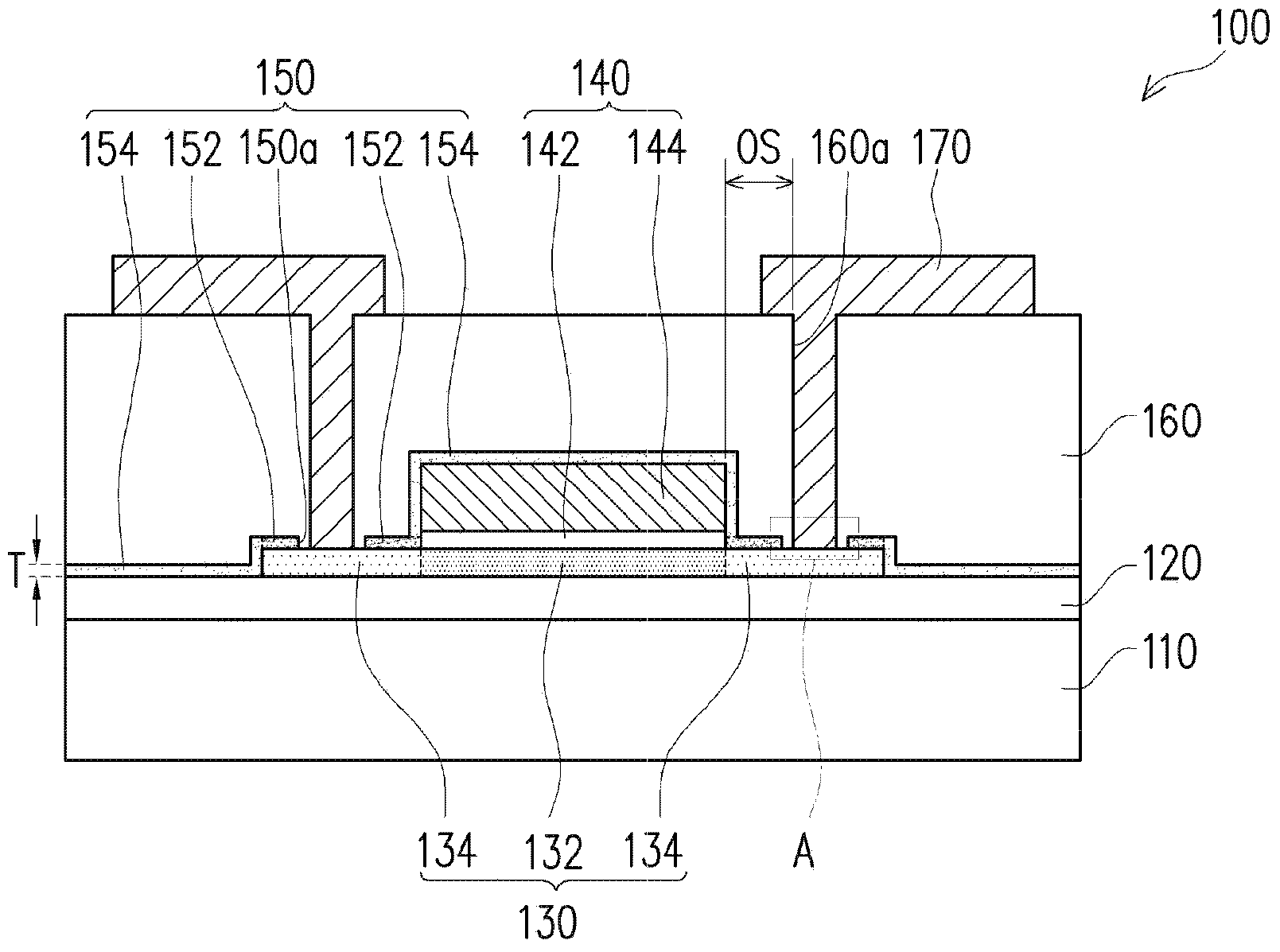

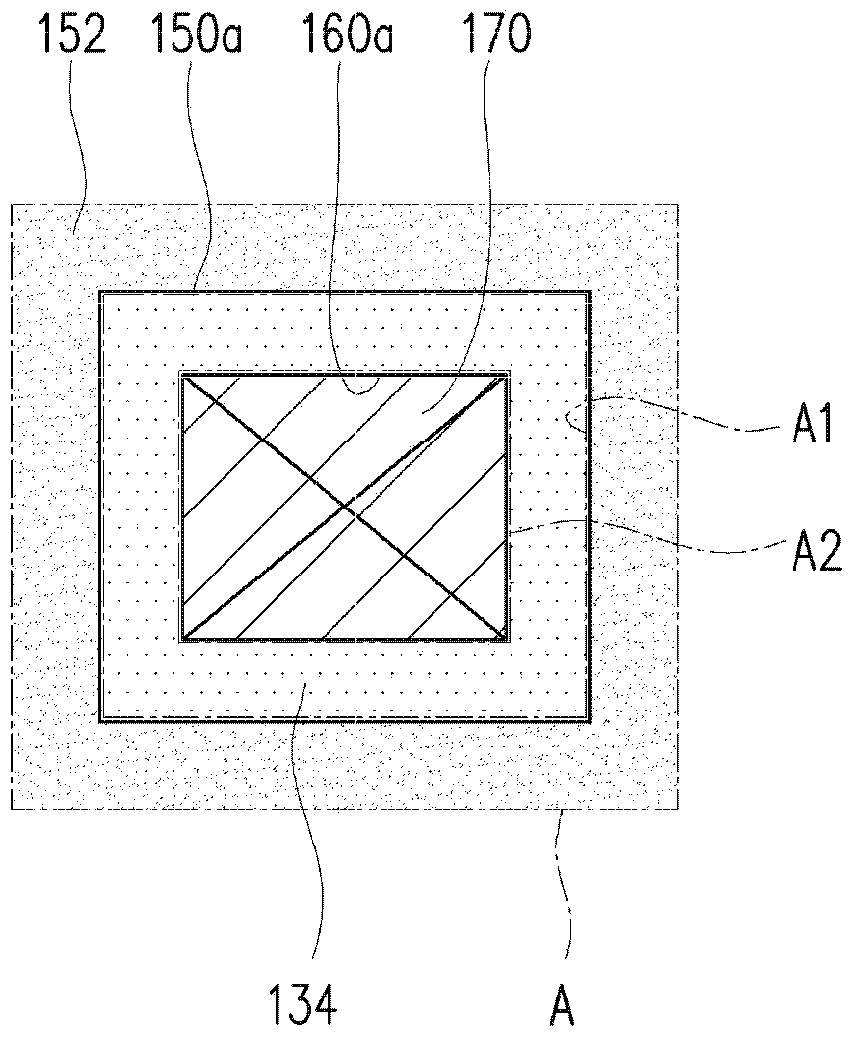

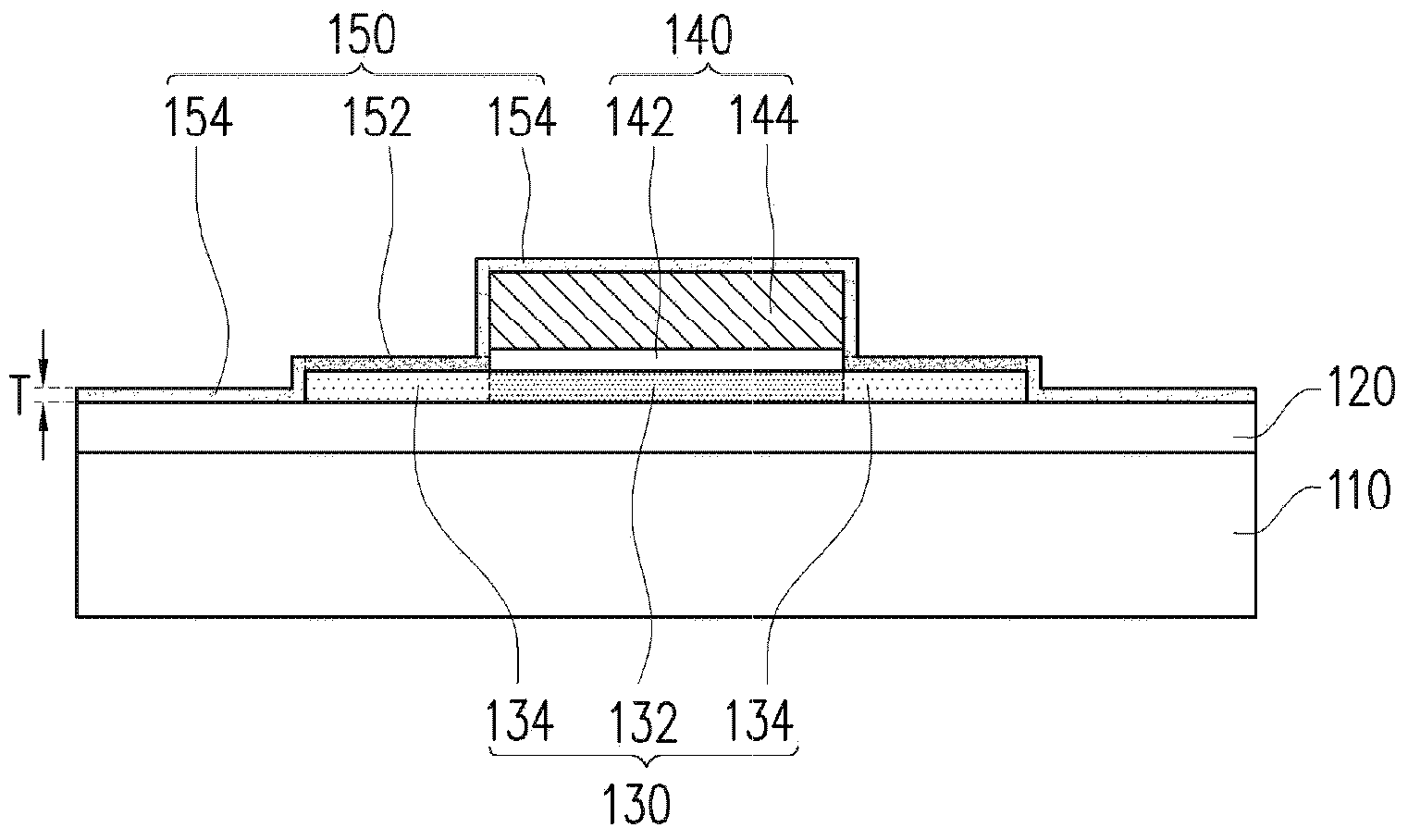

[0039] figure 1 is a schematic cross-sectional view of a thin film transistor 100 according to the first embodiment of the present invention, and figure 2 yes figure 1 A schematic top view of area A in , wherein the area A is the area of one of the first openings.

[0040] The thin film transistor 100 is disposed on a substrate 110 . The material of the substrate 110 is, for example, glass, quartz, organic polymer or metal. Furthermore, in this embodiment, the buffer layer 120 is disposed between the thin film transistor 100 and the substrate 110 , that is, the buffer layer 120 may be disposed on the substrate 110 . The material of the buffer layer 120 is, for example, oxide. However, the present invention is not limited thereto. In other embodiments of the present invention, the buffer layer 120 may not be included, as long as the substrate 110 can withstand the photolithography and etching process in the manufacturing method of the thin film transistor 100 .

[0041...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com