Preparation method of high-viscosity ultra-fine dispersion anode slurry of lithium ion battery

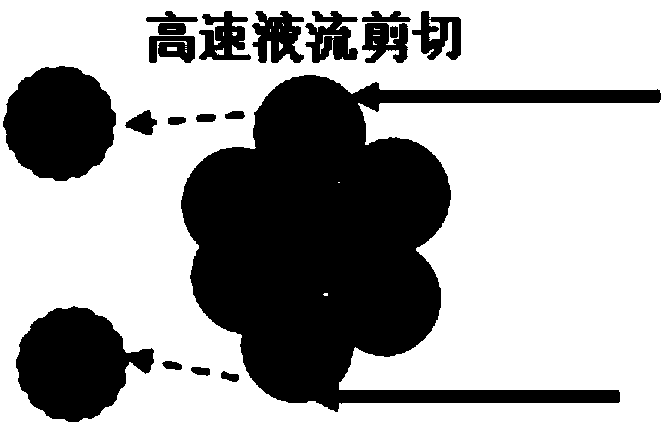

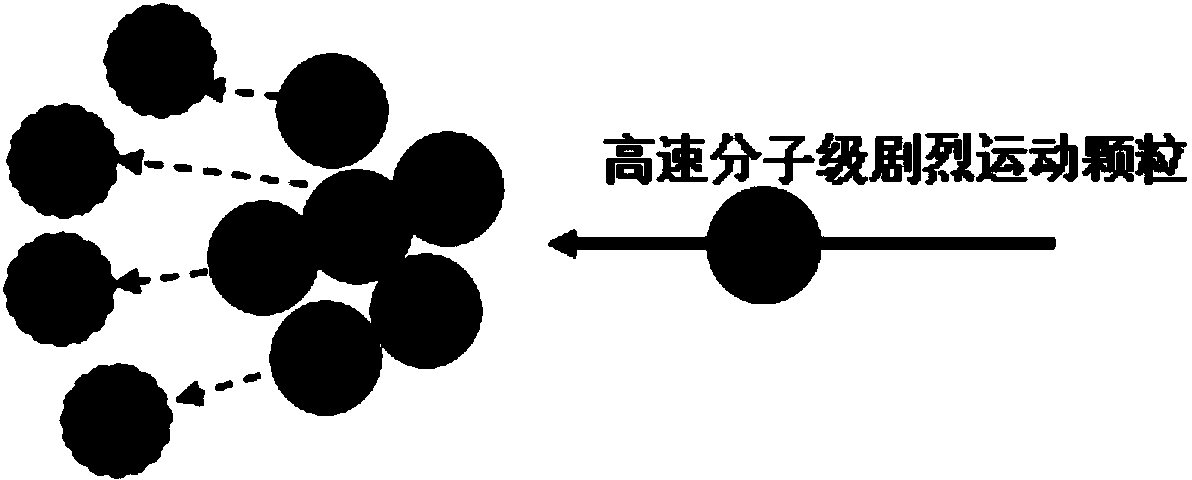

A lithium-ion battery and positive electrode slurry technology, which is applied in battery electrodes, secondary batteries, circuits, etc., can solve the problems of limited ultra-fine dispersion, poor suspension, large slurry particles, etc., and achieve excellent performance and consistency. Avoid the dead angle of the slurry and the effect of low viscosity of the slurry

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

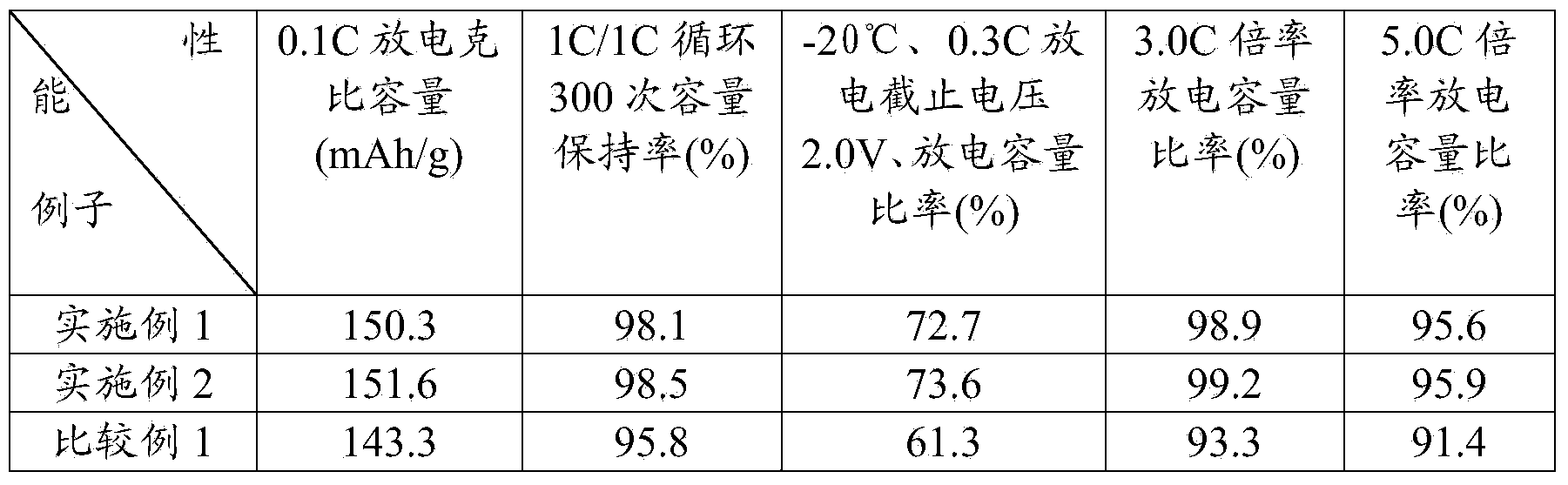

Embodiment 1

[0025] The lithium ion battery positive electrode slurry of the present embodiment is made of N-methylpyrrolidone (NMP), binder polyvinylidene fluoride, nanometer composite conductive agent, LiFePO 4 The positive electrode material is mixed, polyvinylidene fluoride, nano-micro composite conductive agent, LiFePO 4 The weight ratio of the positive electrode material is polyvinylidene fluoride: nano-micron composite conductive agent: positive electrode material=4.5%: 3.5%: 92.0%, wherein 3.5% nano-micron composite conductive agent is composed of 1.0% nanoscale conductive agent Super-P, Composed of 2.0% micron-sized conductive graphite KS-6 and 0.5% carbon nanotubes. The preparation of the positive electrode slurry in this embodiment specifically includes the following steps:

[0026] 1. Add the binder polyvinylidene fluoride (PVDF) to the 15wt% solvent in a high-viscosity mixer, turn on the circulating water, raise the temperature and keep the temperature of the solvent at 60±5°...

Embodiment 2

[0033] The lithium ion battery positive electrode slurry of the present embodiment is made of N-methylpyrrolidone (NMP), binder polyvinylidene fluoride, nanometer composite conductive agent, LiFePO 4 The positive electrode material is mixed, polyvinylidene fluoride, nano-micro composite conductive agent, LiFePO 4 The weight ratio of the positive electrode material is polyvinylidene fluoride: nano-micron composite conductive agent: positive electrode material=5.0%: 3.5%: 91.5%, wherein 3.5% nano-micron composite conductive agent is composed of 1.0% nanoscale conductive agent Super-P, Composed of 1.5% micron-sized conductive graphite KS-6 and 1.0% carbon nanotubes. The preparation of the positive electrode slurry in this embodiment specifically includes the following steps:

[0034] 1. Add the binder polyvinylidene fluoride (PVDF) to the 30Wt% solvent in a high-viscosity mixer, turn on the circulating water, raise the temperature and keep the solvent temperature at 60±5°C, and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com