A semiconductor laser with a new near-cavity surface current non-injection region structure and its manufacturing method

A laser, non-injection technology, used in semiconductor lasers, lasers, laser parts, etc., can solve the problems of serious beam divergence and lack of restrictions, and achieve the effects of simple preparation process, suppression of divergence, and improvement of COD threshold.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings.

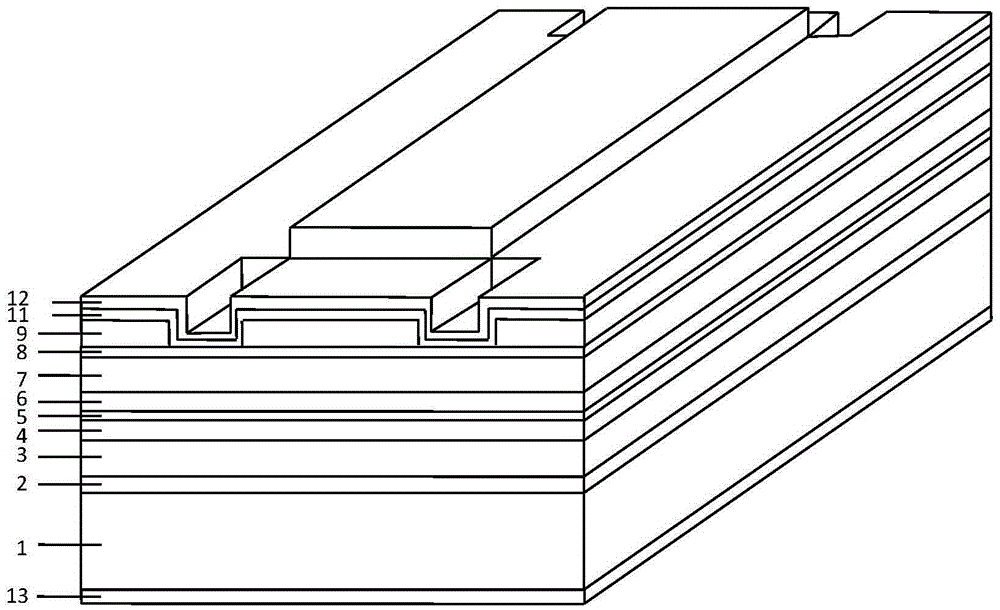

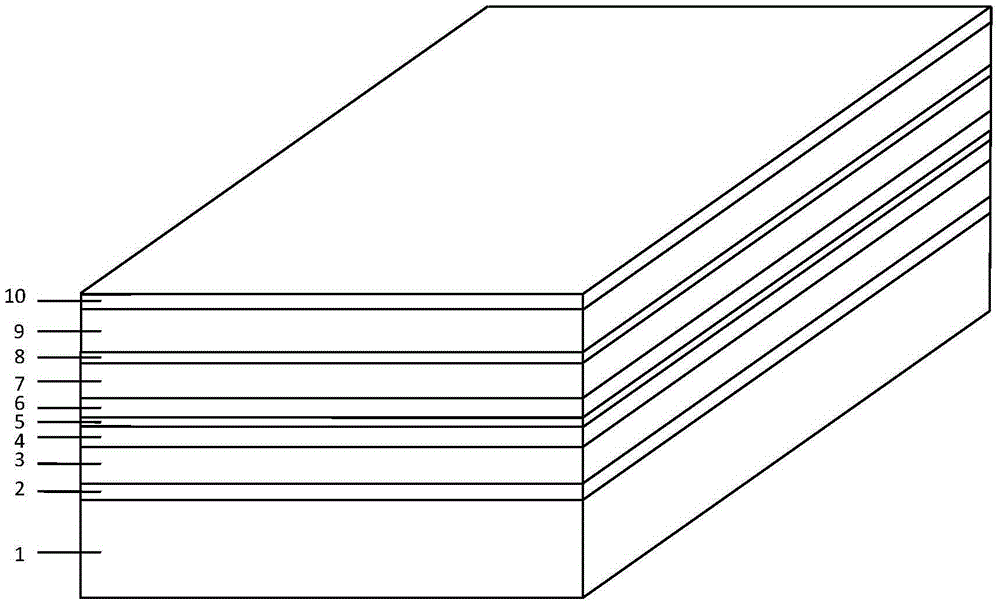

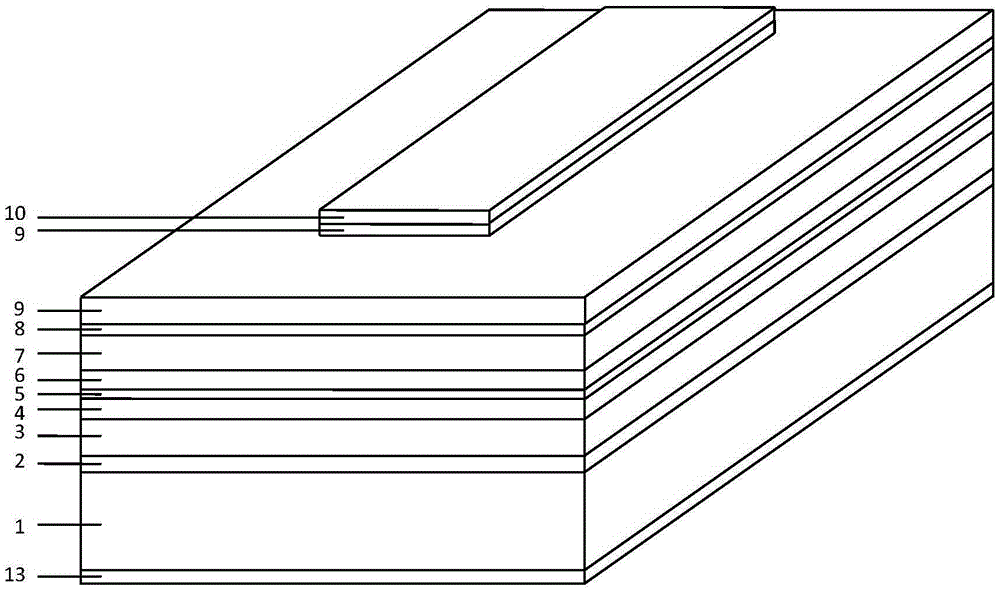

[0028] like figure 1 Shown is a schematic structural diagram of a semiconductor laser with a new near-cavity surface current non-injection region structure, which includes a substrate 1, a buffer layer 2, a lower confinement layer 3, a lower waveguide Layer 4, active layer 5 with quantum well structure, upper waveguide layer 6, second upper confinement layer 7, etch stop layer 8, first upper confinement layer 9, ohmic contact layer 10, electrical insulating medium layer 11, front Electrode 12 and back electrode 13; wherein substrate 1, buffer layer 2, lower confinement layer 3, lower waveguide layer 4, active layer 5 with quantum well structure, upper waveguide layer 6, second upper confinement layer 7, etch The stop layer 8, the first upper confinement layer 9, and the ohmic contact layer 10 are adjacent to each other from bottom to top, and the four sides of the ohm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com