Magnetic composite particles for decontamination and method for producing same, and system for decontaminating radioactive materials and method for decontaminating radioactive materials

A technology of magnetic composite particles and radioactive substances, applied in the field of radioactive substance decontamination systems, to achieve the effects of high-efficiency removal, high environmental resistance, and improved environmental resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach ]

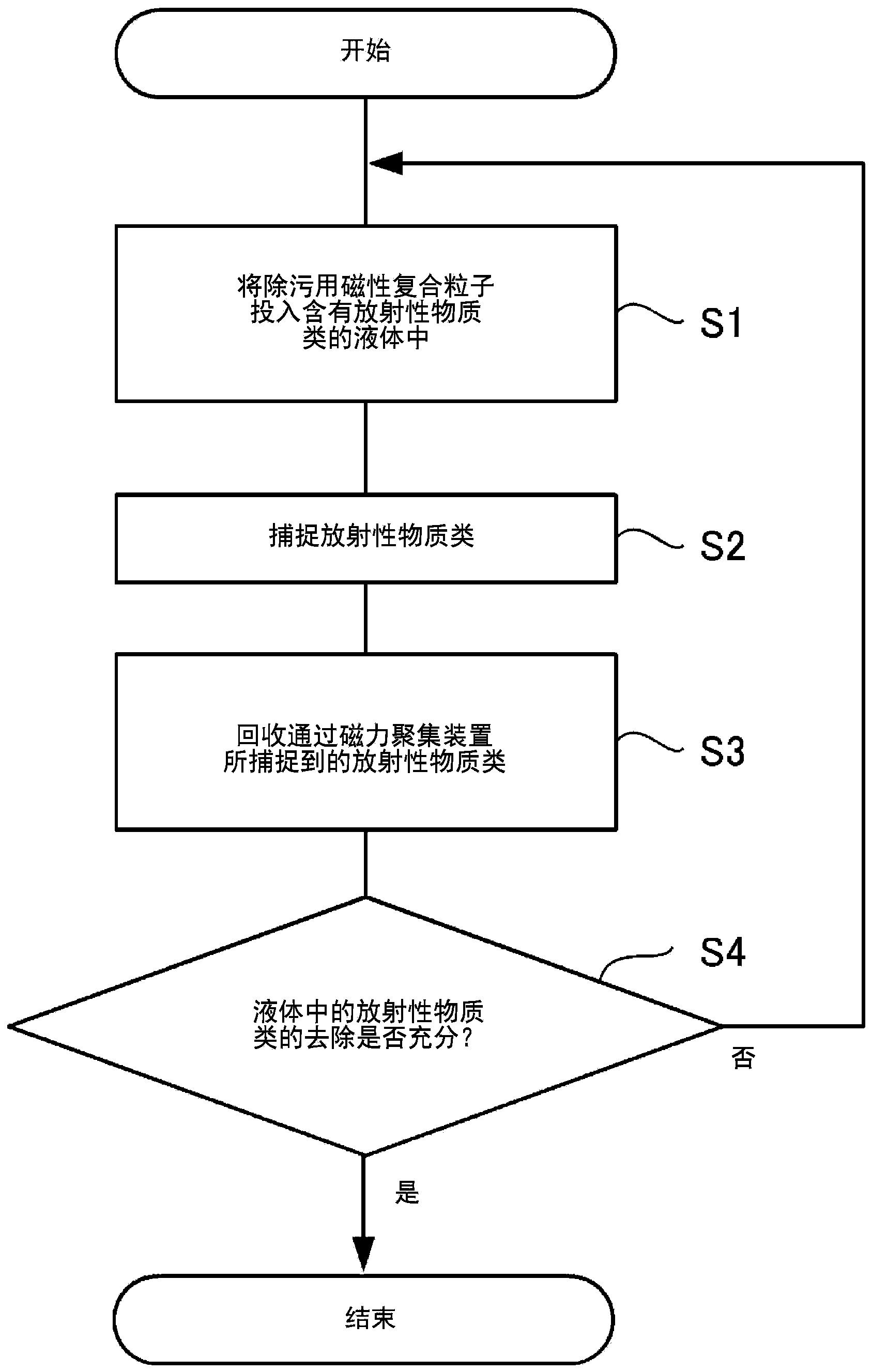

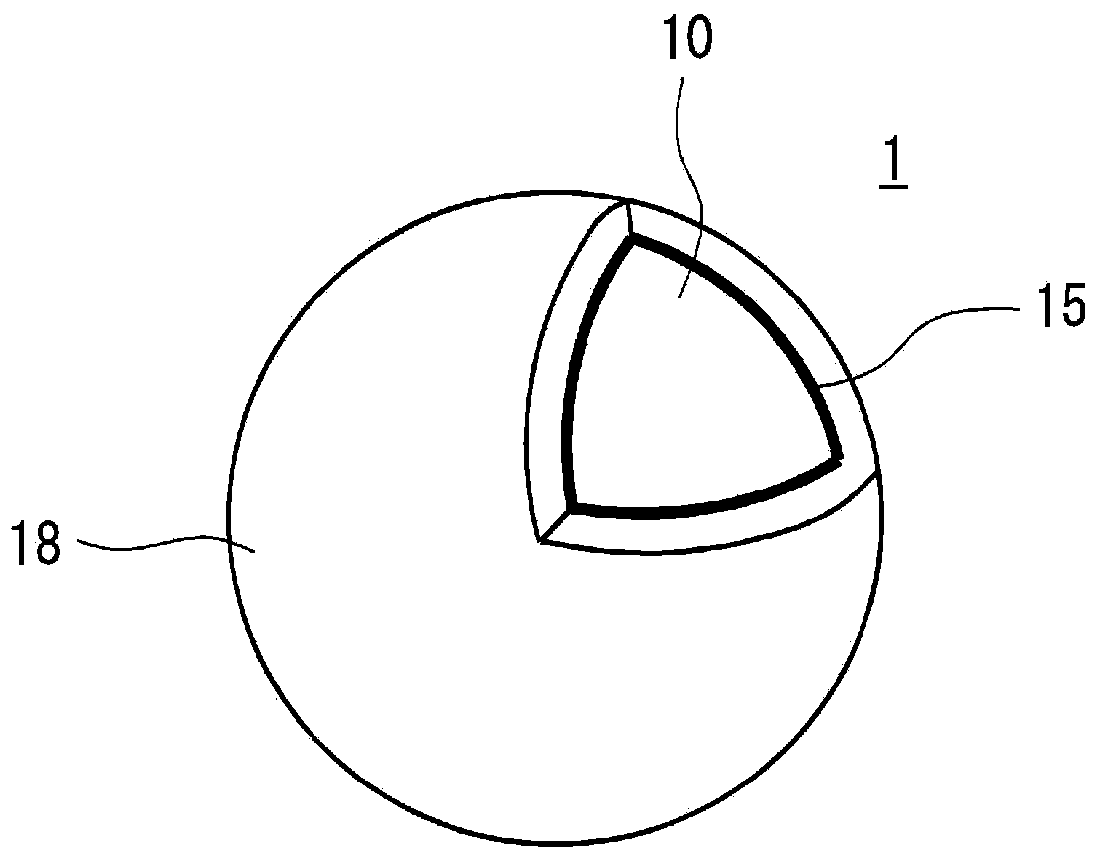

[0068] For the radioactive substance decontamination system of the present invention, while using Figure 1 ~ Figure 3D side to explain. figure 1 It is a flow chart of the radioactive substance decontamination method of the first embodiment. Figure 2A It is a schematic explanatory diagram of the magnetic composite particle for decontamination of the first embodiment; Figure 2B is a partial exploded view of magnetic composite particles for decontamination; Figure 2C yes Figure 2A The cross-sectional view of the IIC-IIC cut-off part. in addition, Figure 2D ~ Figure 2I These are explanatory diagrams and the like showing how clusters are formed in the magnetic nanoparticles of the decontamination magnetic composite particles. Figure 3A ~ Figure 3D It is explanatory drawing of the radioactive substance decontamination system of 1st Embodiment.

[0069] In addition, radioactive substances are a general term for substances with radioactive energy, and they refer to nuclea...

no. 2 Embodiment approach ]

[0119] Next, an example of a radioactive material-based decontamination method different from the above-described embodiment will be described. The radioactive material decontamination method of the second embodiment is basically the same as that of the above-mentioned first embodiment except for the following points. That is, the method for recovering the decontamination magnetic composite particles in the radioactive substance decontamination method of the second embodiment is different from that of the first embodiment. In the first embodiment, the magnetic concentration device is directly immersed in the liquid containing radioactive substances and then pulled up, but in the second embodiment, it is recovered and decontaminated through a filter that can capture magnetic nanoparticles With magnetic composite particles, the two are different in this point.

[0120] Figure 5A and Figure 5B It is a schematic explanatory drawing which shows an example of the radioactive su...

no. 2 Embodiment approach

[0137] According to the second embodiment, since the filtration method and the magnetic control unit 42 are used together to capture and recover the decontamination magnetic composite particles, radioactive substances can be recovered efficiently. The method of the second embodiment may be combined with the method of the first embodiment. For example, it is also possible to relatively reliably recover radioactive substances by removing most of the radioactive substances in the first embodiment and then using the magnetic filter of the second embodiment. In addition, when the magnetic metal mesh 45 is laminated as a magnetic filter, the magnetic adsorption efficiency can be improved. Additionally, when using Figure 5A In the case of the magnetic filter shown in FIG. 5 , since the magnetic metal mesh 45 is laminated and sintered, it is possible to prevent the laminated magnetic metal mesh 45 from being cracked, deformed, etc. due to external force, and further Provides a high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com