Embolism material composition as well as preparation method and use thereof

A technology of embolization and raw materials, which is applied in the field of embolization materials and its preparation, can solve the problems affecting the curative effect and safety of embolization therapy, and the inability to timely and accurately judge the position of embolism agent and the end point of embolization, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0078] Embodiment 1: Preparation of embolic material

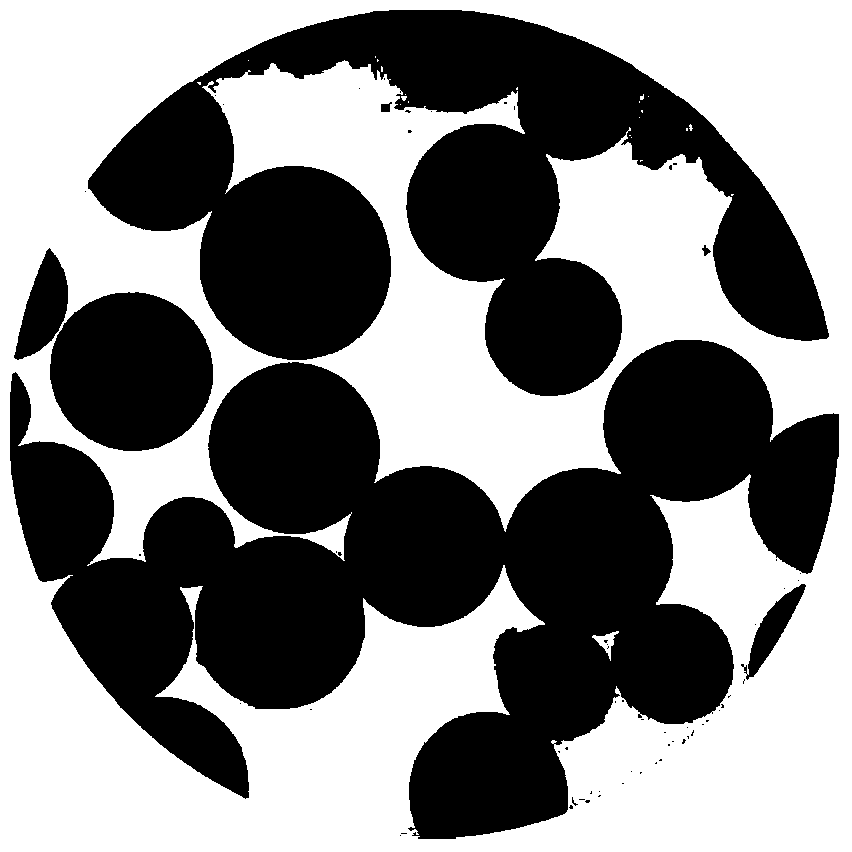

[0079] (1) Mix 0.45g of acrylic acid, 0.55g of 2-acrylamido-2-methylpropanesulfonic acid, 0.027g of N,N'-methylenebisacrylamide, 0.024g of potassium persulfate and 0.089g of tetramethylethylene disulfide Dissolve the amine in water, add the mixed solution into 40ml of liquid paraffin containing 0.005g of Span 80 under stirring, react at 55°C for 4h, collect the prepared blank microspheres, and the morphology of the microspheres under an optical microscope is as follows: figure 1 shown;

[0080] (2) Soak the blank microspheres in a solution containing 0.14g of ferric iron and 0.07g of ferrous iron, pass nitrogen into the solution, and soak for 60min;

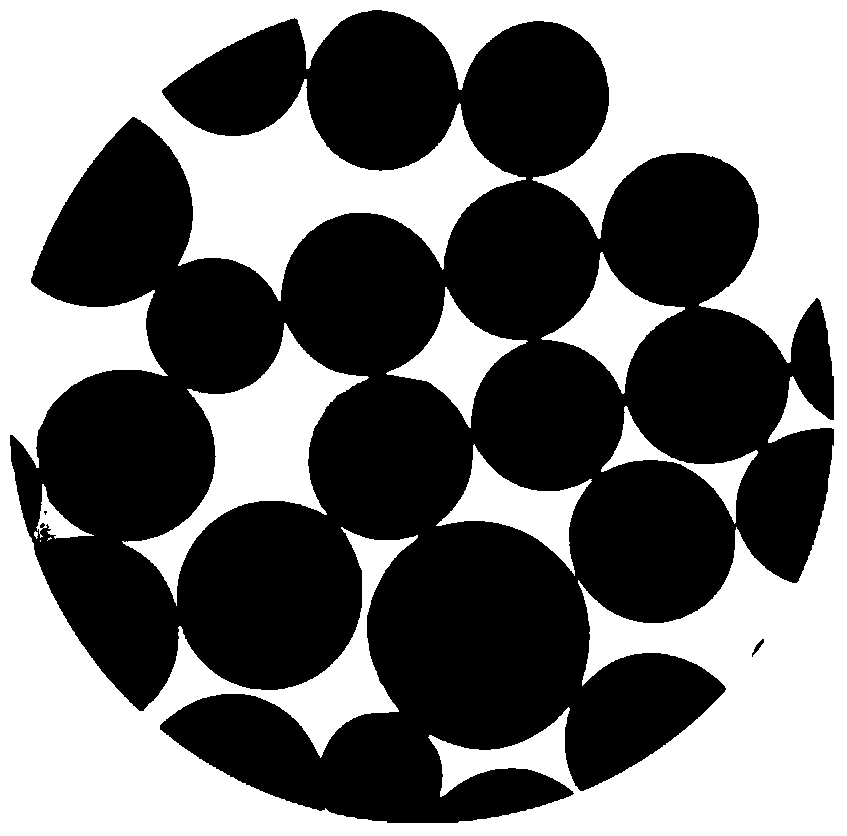

[0081] (3) Add 8 mol / L sodium hydroxide solution to the system at 60-100°C under stirring conditions, adjust the pH value to 8-14, react for 60 minutes, and collect the prepared embolization microspheres. The following form is as figure 2 shown.

Embodiment 2

[0082] Embodiment 2: Preparation of embolic material

[0083] (1) Introduce nitrogen into the solution containing 0.34g ferric iron and 0.16g ferrous iron;

[0084] (2) Add 3mol / L diisopropanolamine solution to the system under stirring at 100°C, adjust the pH value to 8-14, react for 120min, and collect the obtained magnetic particles;

[0085] (3) Add magnetic particles to an aqueous solution containing 1g of acrylic acid, 0.2g of polyvinyl alcohol, 0.007g of N,N'-methylenebisacrylamide, 0.01g of potassium persulfate and 0.005g of tetramethylethylenediamine, The mixture was added to 50 ml of liquid paraffin containing 0.04 g of Span 80, reacted at 65° C. for 5 h, and the prepared embolization microspheres were collected.

Embodiment 3

[0086] Embodiment 3: Preparation of embolic material

[0087](1) Dissolve 1g of acrylic acid, 0.0002g of N,N'-methylenebisacrylamide, 0.0003g of potassium persulfate and 0.0005g of tetramethylethylenediamine in water, and add the mixture to the 0.028g In 40ml of liquid paraffin of Span 80, react at 50°C for 4h, and collect the prepared blank microspheres;

[0088] (2) Soak blank microspheres in a solution containing 9.8g of ferric iron and 4.9g of ferrous iron, pass nitrogen into the solution, and soak for 60 minutes;

[0089] (3) Add 25% w / w ammonia solution to the system under stirring conditions at 60-100°C, adjust the pH value to 8-14, react for 60 minutes, and collect the prepared embolization microspheres.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com