Preparation method of rare-earth modified MCM-48 loaded double-function catalyst

A MCM-48, bifunctional catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, etc., can solve the problem of poor preparation repeatability, reduced specific surface area, Low acid strength, etc., to achieve the effect of enhanced catalytic activity, enhanced hydrothermal stability, and enhanced acidity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

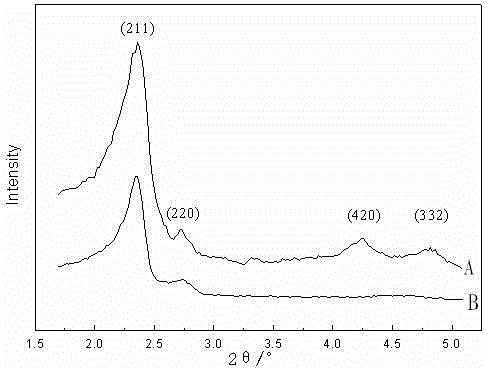

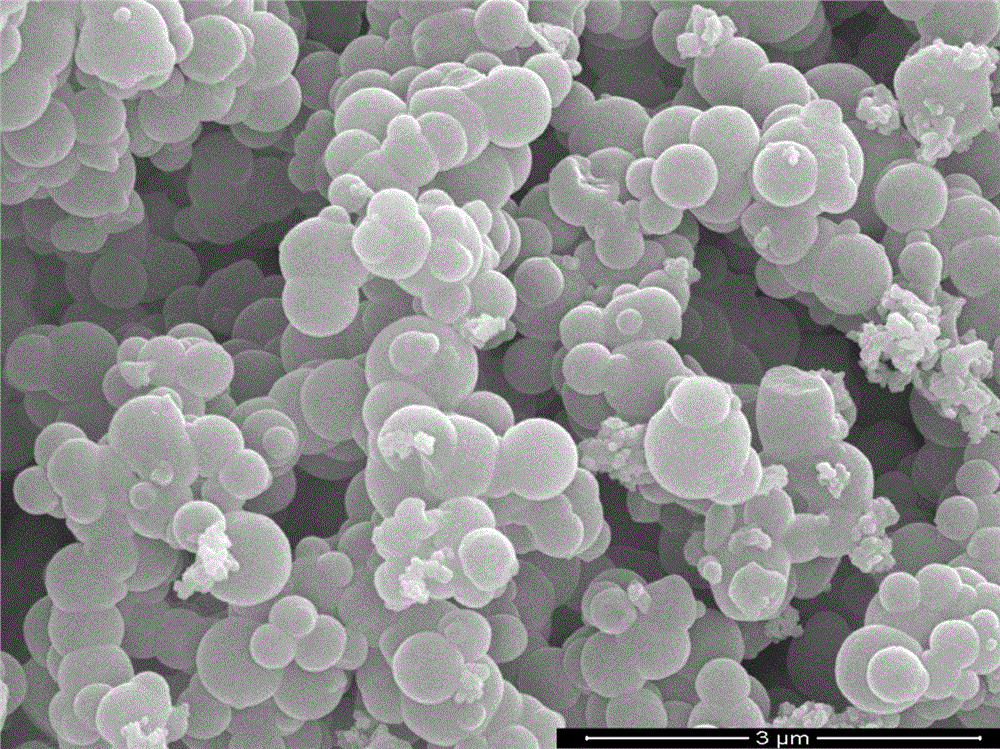

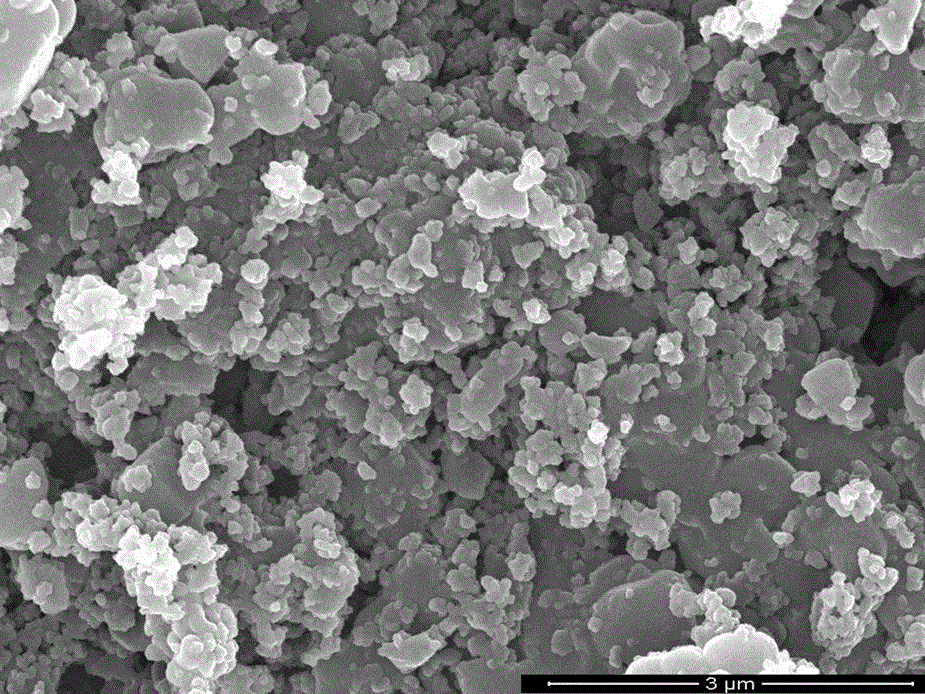

Embodiment 1

[0031] Mix 10mL tetraethyl orthosilicate and 40mL deionized water and vibrate for 40min under the assistance of ultrasonic waves, then add 5mL of 4.5mol / L sodium hydroxide solution into the mixed solution, and then introduce 5mL of 0.27mol / L cerium nitrate solution, And oscillating for 60min under the assistance of ultrasonic waves, 10.61g cetyltrimethylammonium bromide was added to the mixed solution, and continued to oscillate for 60min under the assistance of ultrasonic waves, the gel ratio of the mixture was 1.0TEOS:0.65CTAB:0.5NaOH :62H 2 O, the Ce / Si ratio is 0.03. The mixed gel was put into an autogenous pressure stainless steel reactor lined with polytetrafluoroethylene, and statically crystallized at 120 °C for 3 days. The crystallized product was filtered under low pressure, washed with deionized water until the pH was neutral, and dried in a constant temperature oven at 100°C for 10 hours to remove excess water to obtain the original powder of Ce-MCM-48. The raw p...

Embodiment 2

[0036] Mix 10mL tetraethyl orthosilicate and 40mL deionized water and vibrate for 40min under the assistance of ultrasonic waves, then add 5mL of 4.5mol / L sodium hydroxide solution into the mixed solution, and then introduce 5mL of 0.27mol / L cerium nitrate solution, And oscillating for 60min under the assistance of ultrasonic waves, 10.61g cetyltrimethylammonium bromide was added to the mixed solution, and continued to oscillate for 60min under the assistance of ultrasonic waves, the gel ratio of the mixture was 1.0TEOS:0.65CTAB:0.5NaOH :62H 2O, the Ce / Si ratio is 0.03. The mixed gel was put into an autogenous pressure stainless steel reactor lined with polytetrafluoroethylene, and statically crystallized at 120 °C for 3 days. The crystallized product was filtered under low pressure, washed with deionized water until the pH was neutral, and dried in a constant temperature oven at 100°C for 10 hours to remove excess water to obtain the original powder of Ce-MCM-48. The raw po...

Embodiment 3

[0041] Mix 10mL tetraethyl orthosilicate and 40mL deionized water and vibrate for 40min under the assistance of ultrasonic waves, then add 5mL of 4.5mol / L sodium hydroxide solution into the mixed solution, and then introduce 5mL of 0.27mol / L cerium nitrate solution, And oscillating for 60min under the assistance of ultrasonic waves, 10.61g cetyltrimethylammonium bromide was added to the mixed solution, and continued to oscillate for 60min under the assistance of ultrasonic waves, the gel ratio of the mixture was 1.0TEOS:0.65CTAB:0.5NaOH :62H 2 O, the Ce / Si ratio is 0.03. The mixed gel was put into an autogenous pressure stainless steel reactor lined with polytetrafluoroethylene, and statically crystallized at 120 °C for 3 days. The crystallized product was filtered under low pressure, washed with deionized water until the pH was neutral, and dried in a constant temperature oven at 100°C for 10 hours to remove excess water to obtain the original powder of Ce-MCM-48. The raw p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com