Manufacturing method of wiring pipe holes in composite batten wall and special manufacturing equipment

A technology of composite strip wall and manufacturing method, which is applied in the direction of manufacturing tools, stone processing equipment, stone processing tools, etc., can solve the problems of high construction labor intensity, affecting the quality of the wall, hindering the promotion and application, etc., and achieve the reduction of wall repair Work load, beautiful appearance, labor-saving effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

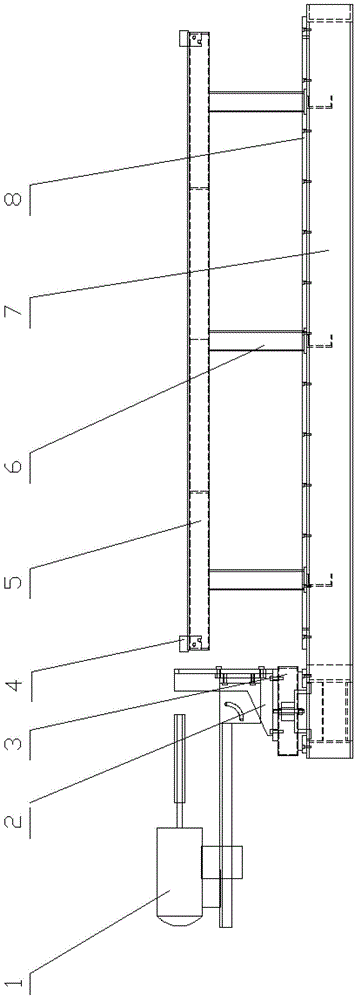

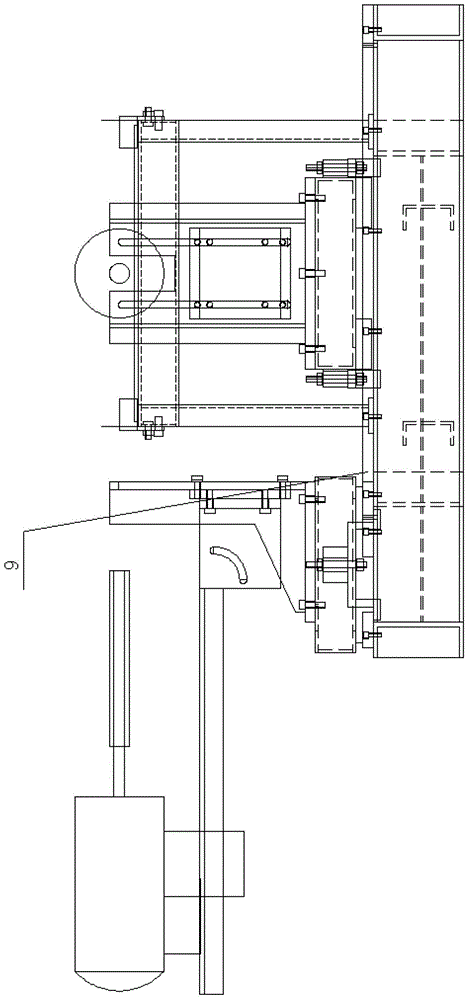

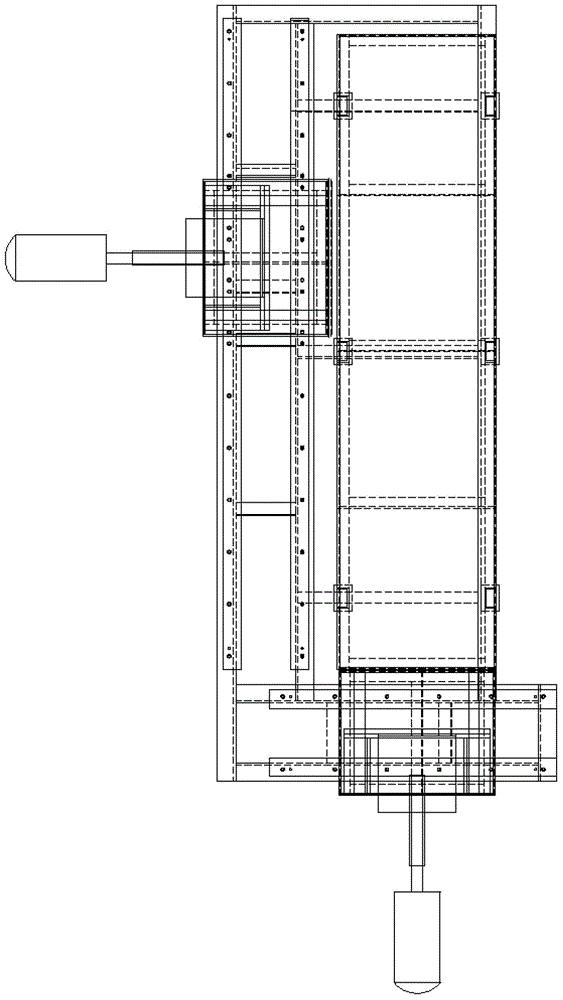

[0020] refer to Figure 1 to Figure 5 , the manufacturing method of threading pipe hole in composite strip wall, described method comprises the following steps:

[0021] (1) Place the composite slat wall on the working table of the special threading pipe drilling equipment. The above-mentioned special drilling equipment can simultaneously carry out drilling construction on the slat wall in both longitudinal and horizontal directions;

[0022] (2) Determine the position, depth and diameter of the drilled holes on the composite slat wall;

[0023] (3) Move and fasten the drilling power head so that it can be accurately positioned and clamped on the drilling part of the slat wall, and the special drill bit is used to drill the slat wall through the rotation and working feed of the drilling power head , when the required depth is reached, return the drilling power head;

[0024] (4) At the end of the drilled hole, that is, where the switch or socket box is installed, use a hand-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com