Sample sack for measuring dry matter degradation rate of fodder in rumen and application method thereof

A technology of dry matter and degradation rate, applied in bags, sacks, weighing by removing certain components, etc., can solve the problems of complicated operation steps, poor comparability of results, large washing loss, etc., and achieve good repeatability and accuracy. High, simple operation steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 The present invention measures the preparation of the sample bag of feed rumen dry matter degradation rate

[0026] 1. the special sample bag raw material weight 50-60g / m of the present invention 2 , pore size 20-30μm, tear strength greater than 30N / 5cm non-woven fabrics are folded face to face, the smooth side facing outward, each non-woven fabric width is about 7cm and cut for use.

[0027] 2. Turn on the power supply of the ultrasonic bag sealing machine model cx2000p of Beijing Changhong Jianxiang Technology Development Co., Ltd., set the speed and vibration frequency, adjust the speed of the wheel to the first gear, and adjust the vibration frequency to the second gear. Put the cut non-woven fabric under the wheel of the ultrasonic bag sealing machine, turn on the wheel switch to squeeze the two cut non-woven fabrics together through pressure vibration. (The dimensions of the mold rollers of the ultrasonic bag sealing machine are 8.5cm in length and 6...

Embodiment 2

[0029] Embodiment 2 The comparison of sample bag of the present invention and traditional nylon bag in measuring feed rumen dry matter degradation rate

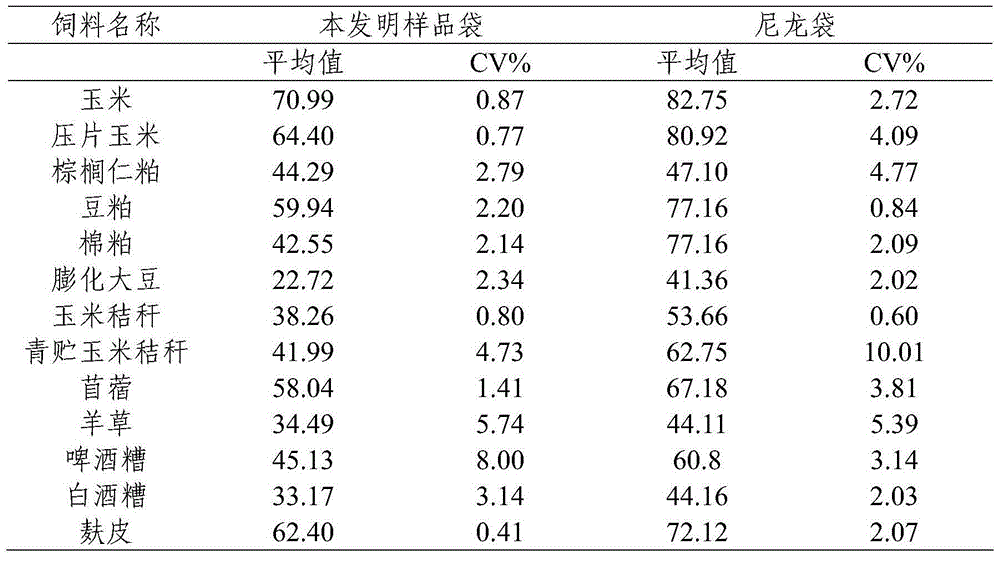

[0030] By using the sample bag of the present invention and the traditional nylon bag (Mo Fang, 2011) to measure corn, flaked corn, palm kernel meal, soybean meal, cotton meal, puffed soybean, corn stover, corn silage straw, alfalfa, chingrass, beer The 24h rumen dry matter degradation rate of 13 kinds of feed materials including distiller's grains, distiller's grains and bran was repeated 9 times for each feed material, and the experimental data were counted. The results of the two methods were compared in Table 1. As can be drawn from Table 1: the 24h feed rumen degradation rate measured by the method of the present invention is lower than that of the nylon bag, and the difference in results may be caused by the greater washing loss of the nylon bag. It can be considered that the rumen dry matter degradation measured by the...

Embodiment 3

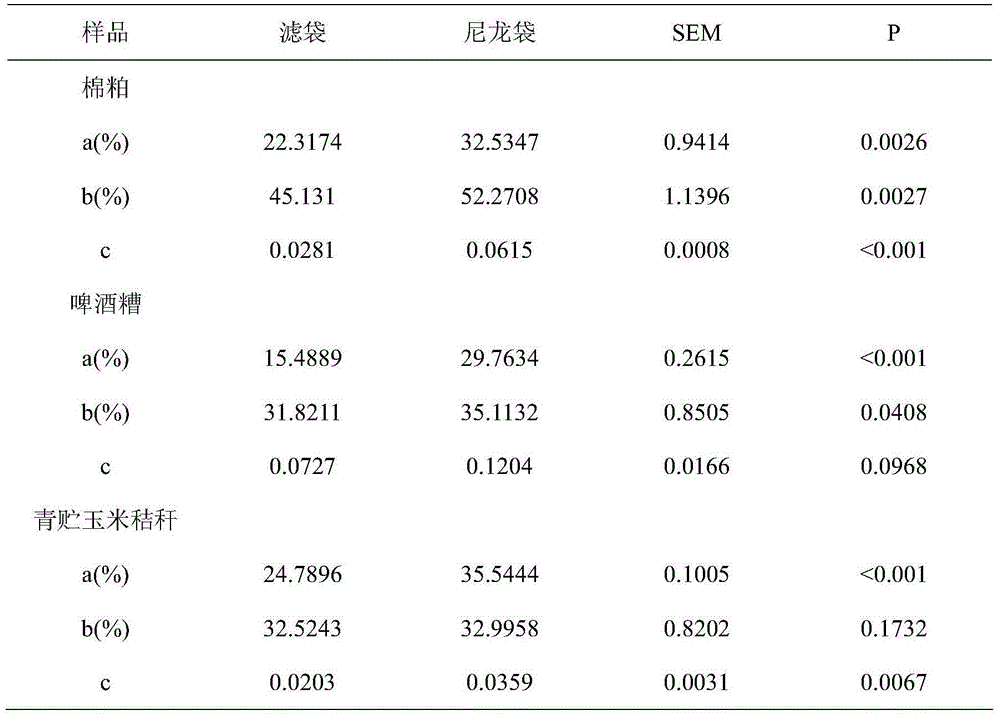

[0034] Embodiment 3 Comparison of sample bag of the present invention and traditional nylon bag in measuring feed dry matter degradation characteristics

[0035] By using the sample bag of the present invention and the traditional nylon bag (Mo Fang, 2011) to measure the degradation rate of ruminal dry matter of cottonseed meal, brewer's grains, and silage corn stalks at different time points, and then use The model of (1979) compared the rumen dry matter degradation characteristics of cottonseed meal, brewer's grains, and silage corn stalks. Nylon bag, probably due to the large pore size and surface area of the nylon bag, resulting in higher washing loss and overestimation of the degradation rate of the feed; there is no significant difference between the two methods for the slowly degraded component roughage corn stalks, and the by-product feed is brewer's grains and protein feed cotton Although the CAU filter bag of meal is significantly lower than that of nylon bag, the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com