Cold ramming paste and cathode carbon block and steel bar combined structure with joint filled by cold ramming paste

A technology of cathode carbon block and cathode steel rod, which is applied in the field of combined structure of cathode carbon block and steel rod, which can solve the problem of lower resistivity of cold ramming, achieve lower resistivity, reduce power consumption per ton of aluminum, and reduce furnace bottom pressure drop Effect

Active Publication Date: 2014-11-26

ZHENGZHOU SIDI NEW MATERIAL CO LTD

View PDF2 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

At present, the resistivity of cold-rammed paste produced in China is generally 60-90μ? m. There are many researches in the industry dedicated to reducing the resistivity of cold-rammed paste, but there is no effective method to make the resistance of cold-rammed paste significantly lower rate

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

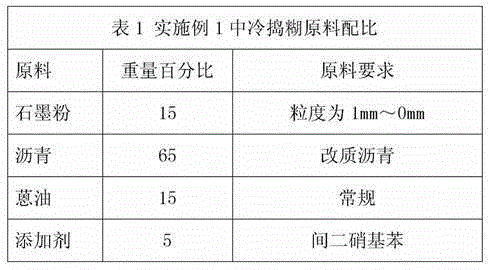

[0022] Embodiment 1: The ratio of raw materials for cold ramming paste is shown in Table 1 below.

[0023]

Embodiment 2

[0024] Embodiment 2: The ratio of raw materials for cold ramming is shown in Table 2 below.

[0025]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Login to View More

Abstract

The invention discloses a cold ramming paste and a cathode carbon block and steel bar combined structure with joint filled by the cold ramming paste, and aims at solving the technical problems of poor electric conductivity and heat conductivity of a conventional cold ramming paste and poor corrosion resistance. The cold ramming paste is prepared by the following raw materials by weight: 8%-20% of graphite powder, 55%-70% of asphalt, 10%-32% of anthracene oil and 3%-6% of an additive. Electrical resistivity of the cold ramming paste is below 45 [mu][ohm].m; compressive strength of the cold ramming paste is 20-25 MPa and a ramming temperature is 8-22.5 DEG C. The cold ramming paste has significantly reduced electrical resistivity and relatively high electric conductivity and corrosion resistance. By applying the cold ramming paste in the cathode carbon block and steel bar combined structure of an aluminium electrolytic cell, pressure drop of cathode steel bar paste and pressure drop of hearth bottom of the aluminium electrolytic cell are effectively reduced; and further power consumption per ton aluminium and CO2 emission of aluminium electrolysis enterprises can be reduced.

Description

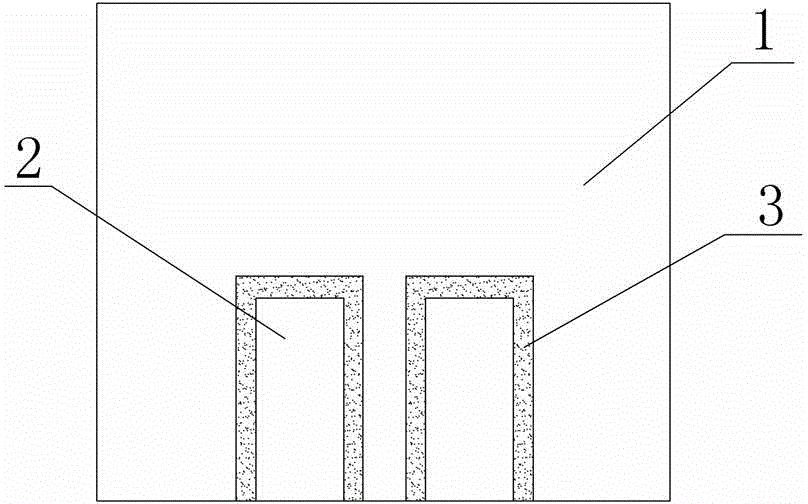

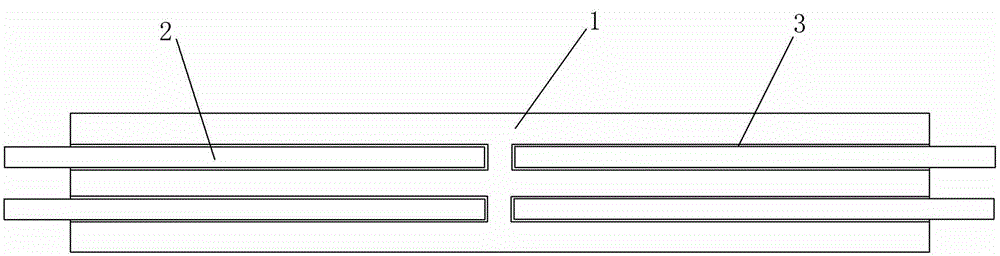

technical field [0001] The invention relates to a cold tamping paste for aluminum electrolysis and a combined structure of cathode carbon block and steel rod for gap filling by using the cold tamping paste. Background technique [0002] Although my country's aluminum electrolysis technology has caught up with the world's advanced level in terms of the capacity of industrialized electrolytic cells, there is still a gap between my country's aluminum electrolytic cells and the international advanced level in terms of life, current efficiency, power consumption, environmental pollution, and health hazards to construction workers. According to the trend of international technology development in recent years, one of the important measures to narrow this gap is to use high-quality cold tamping paste to tamp cathode carbon blocks, thereby reducing energy consumption, improving current efficiency, and increasing the life of the electrolytic cell. [0003] In the aluminum electrolyti...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C04B26/26C25C3/08

Inventor 王旭东和清霖曹国法袁志强朱振国冯晓强

Owner ZHENGZHOU SIDI NEW MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com