Technology for preparing composite desulphurization gypsum building block with gradient structure

A technology of desulfurized gypsum and composite blocks, which is applied in the field of building materials, can solve problems such as groundwater pollution, land occupation, and threats to health, and achieve the effects of improving thermal insulation performance, high utilization rate, and convenient construction and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

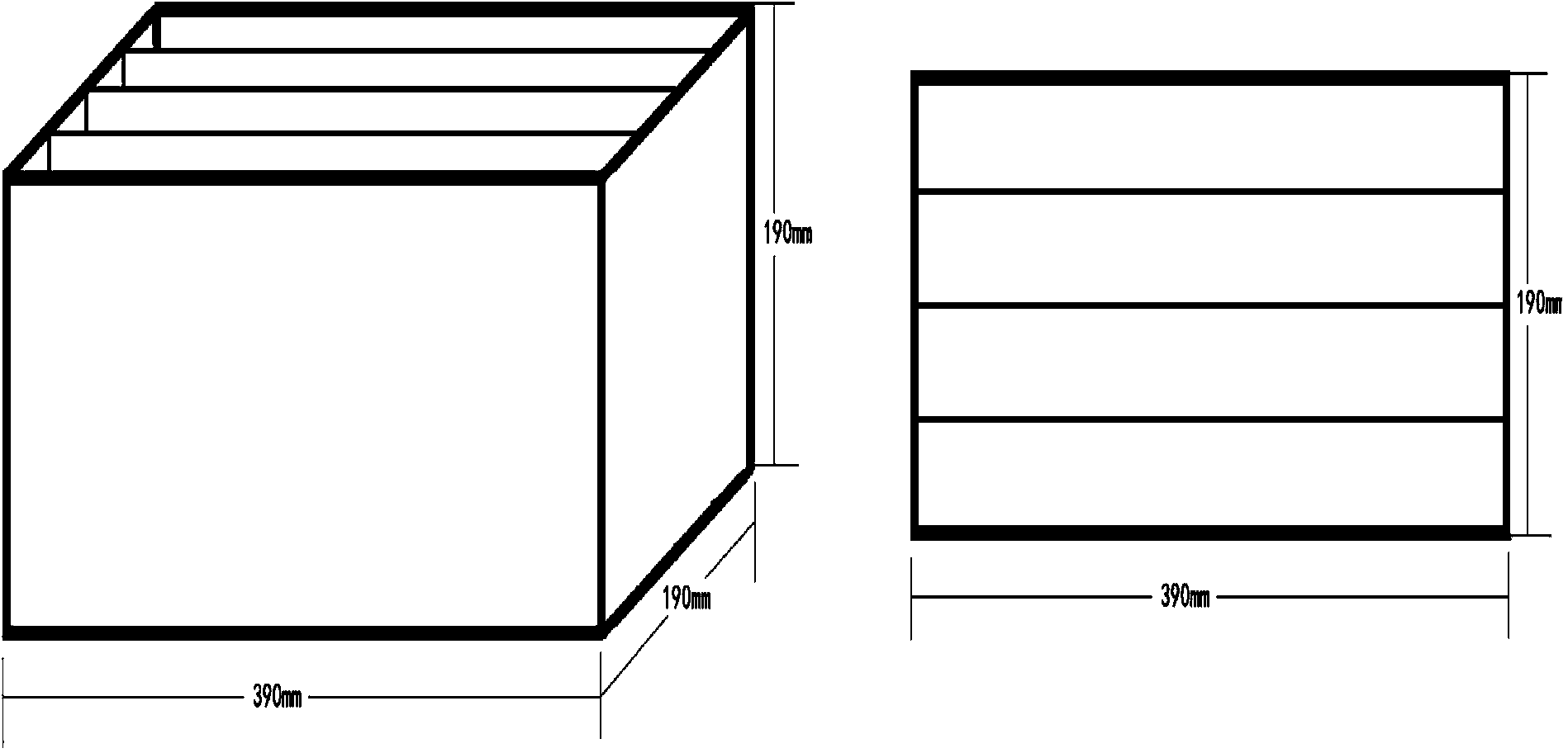

[0021] Heat the pre-prepared cast iron mold that can be evenly divided into 4 grids by the pull-out partition to 35°C. The schematic diagram of the mold is as follows figure 1 shown.

[0022] Prepare 1-4 groups of gypsum composite cementitious material slurry. The same composition of these four groups of slurry is as follows: 60% of desulfurized building gypsum, 12% of ordinary Portland cement, 2% of high alumina cement, 10% of lime and 16% of fly ash are made into powder by mass, FJ- PCEⅡ type polycarboxylate high-efficiency superplasticizer is added in an amount of 1.0% of the powder mass, and citric acid is added in an amount of 0.02% of the powder mass; the water-material ratio is 0.5, and the water temperature is 35°C; from group 1 to group 1 Group 4, the dosage of aluminum powder was 0%, 0.1%, 0.2% and 0.3% respectively.

[0023] The well-stirred slurry of each group is poured into the 4 compartments of the mold to fill them up, and then the separator is pulled out and...

Embodiment 2

[0025] Heat the pre-prepared cast iron mold that can be evenly divided into 5 grids by extractable partitions to 45°C.

[0026] Five groups of gypsum composite cementitious material slurries were prepared. The same composition of these five groups of slurry is as follows: 70% of desulfurized building gypsum, 8% of ordinary Portland cement, 2% of high alumina cement, 10% of lime, and 10% of fly ash are made into powder by mass; FJ-PCEⅡ Type polycarboxylate high-efficiency water reducer is added at 1.0% of the powder mass, and citric acid is added at 0.02% of the powder mass; the ratio of water to material is 0.5, and the water temperature is 45°C; from group 1 to group 5 Group, the amount of aluminum powder were 0.05%, 0.1%, 0.15%, 0.2% and 0.25%.

[0027] The well-stirred slurry of each group was poured into the 5 compartments of the mold to fill them up, and then the separator was pulled out and smoothed; after that, it was placed at a constant temperature of 35°C and kept f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com