Environment-friendly magnesia-chrome brick for steel refining and non-ferrous metal smelting and preparation method thereof

A technology of non-ferrous metals and magnesia-chrome bricks, applied in the field of magnesia-chrome refractory materials, can solve problems such as human and environmental hazards, strong carcinogenic fractures, etc., and achieve significant economic benefits, benefit human health, and far-reaching historical significance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0053] The specific embodiment of the present invention is further described below:

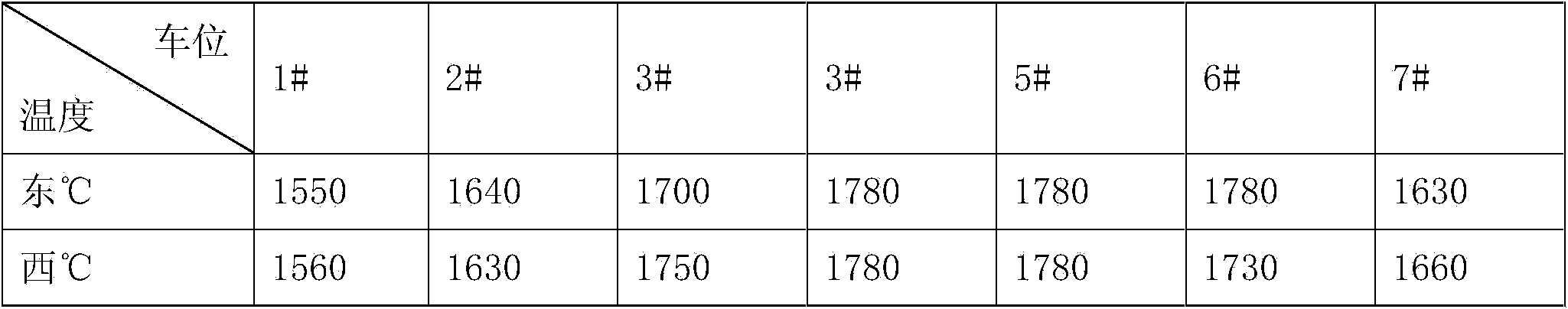

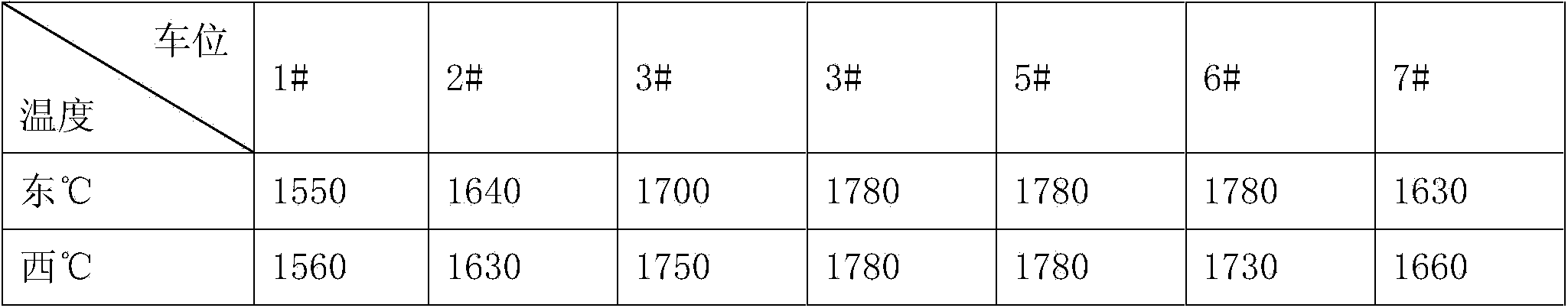

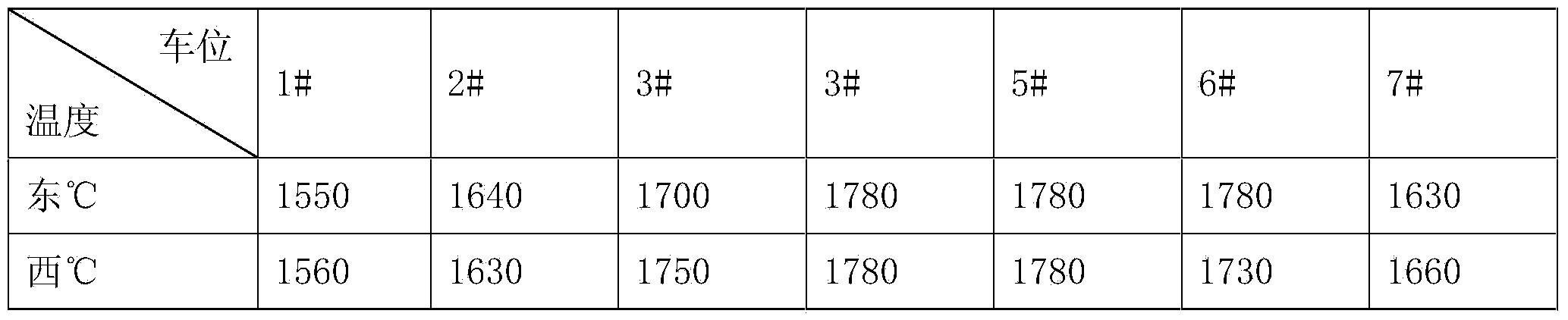

[0054] The present invention is an environment-friendly magnesia-chrome brick for iron and steel refining and non-ferrous metal smelting, and the weight ratio of the magnesia-chrome brick is shown in Table 3:

[0055] Table 3 Proportion examples of environmentally friendly magnesia-chrome bricks for iron and steel refining and non-ferrous metal smelting

[0056] ingredients

[0057] 0

[0058] The preparation method of above-mentioned embodiment 1-4 is identical, and completes according to the following steps:

[0059] 1) Crushing, screening and fine grinding of raw materials:

[0060] The magnesia is crushed in the crusher to make raw materials with two particle sizes of 1<particle size≤3mm and 0mm<particle size≤0.088mm.

[0061] The magnesia chrome sand is crushed in a crusher to make raw materials with three particle sizes of 3<part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com