Carbon-ceramic composite brake disc and preparation method thereof

A carbon-ceramic composite material and brake disc technology, which is applied in the field of carbon-ceramic composite material and brake disc preparation, can solve the limitations of carbon-ceramic composite brake disc manufacturing and popularization and application, low mechanical properties of materials, and long preparation process cycle and other problems, to achieve the effect of improving anti-oxidation performance, comfortable pedal feeling and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

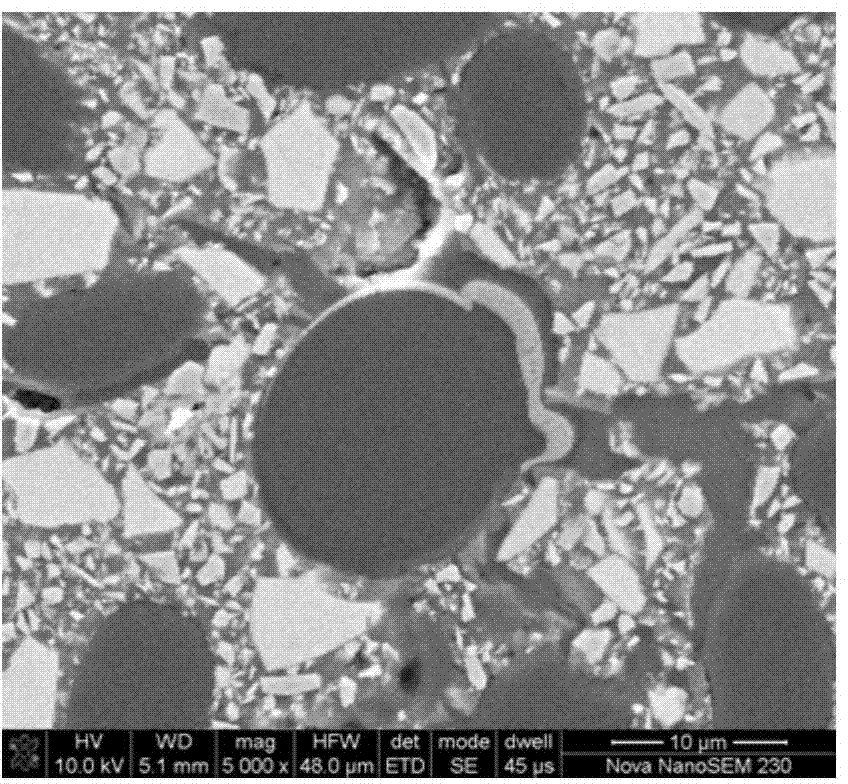

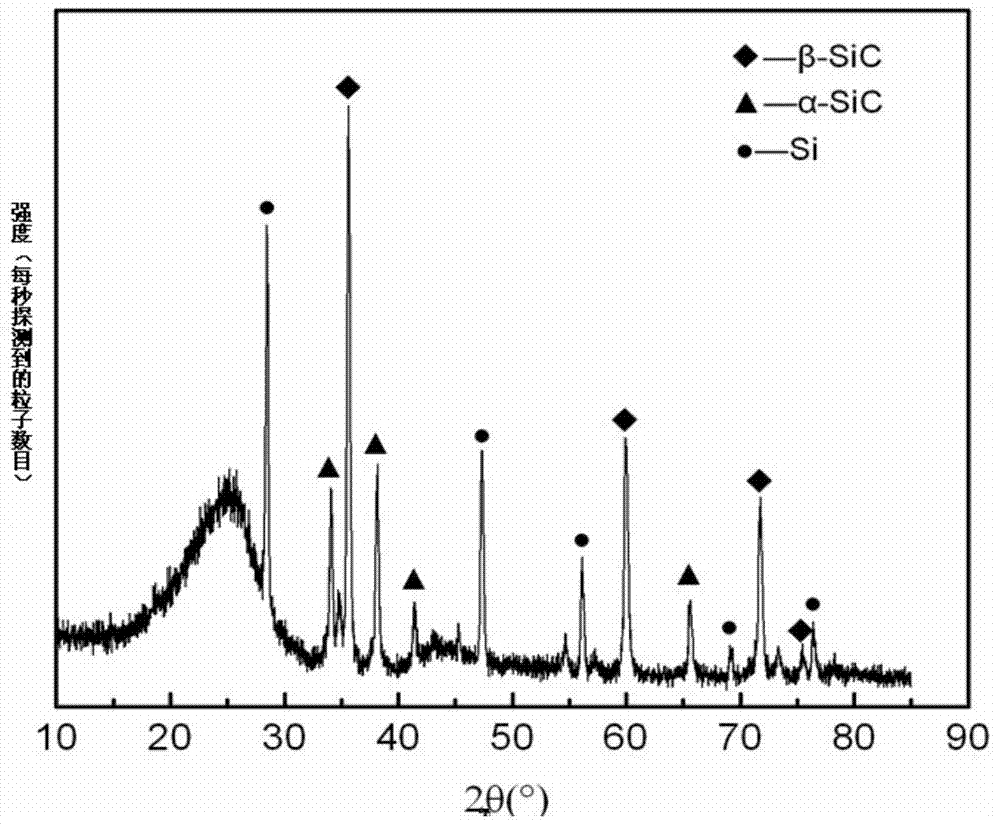

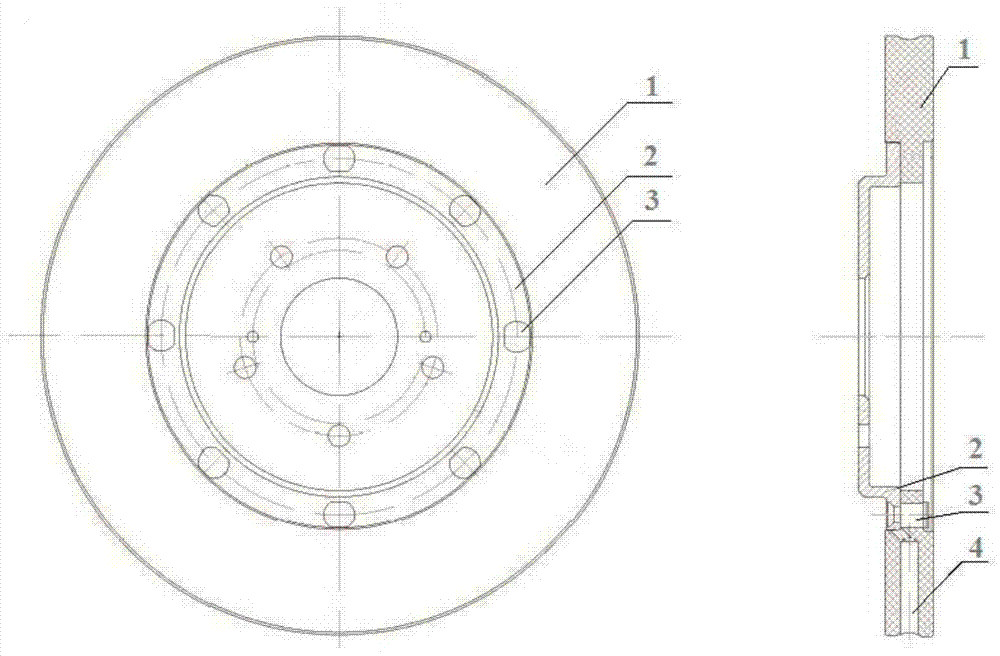

Embodiment 1

[0054] Using the PAN type T700 (12K) carbon fiber bundle produced by Japan's Toray Corporation (Toray), the carbon fiber bundle is passed through the liquid furan resin at a wire speed of 20mm / s, dried and cut to obtain a modified carbon fiber bundle with a length of 15mm. carbon fiber. The phenolic resin powder with a particle size of 99.5%, the average particle size of 30nm, the short carbon fiber of 15mm and absolute ethanol by mass percentage: 30% carbon fiber, 9% silicon powder, 51% After mixing the phenolic resin and 10% absolute ethanol evenly, put it into a mold designed according to the size of the Changfeng CS6 automobile brake disc, hot press at a pressure of 2.0Mpa and a temperature of 140°C, and hold the pressure for 30 minutes After curing at 120°C for 24 hours, the obtained density is 1.26g / cm 3 The carbon fiber reinforced green body (CFRP) has 32 cooling channels. The obtained carbon fiber reinforced green body (CFRP) was then carbonized for 38 hours under an...

Embodiment 2

[0058] Using the PAN type T700 (12K) carbon fiber bundle produced by Toray, Japan, the carbon fiber bundle is passed through the liquid phenolic resin at a wire speed of 18mm / s, dried and cut to obtain a modified carbon fiber bundle with a length of 25mm. carbon fiber. The phenolic resin powder with a particle size of 99.5%, the average particle size of 30nm, the short carbon fiber of 25mm and absolute ethanol are in mass percentage: 36% carbon fiber, 5% silicon powder, 57% After mixing the phenolic resin and 2% absolute ethanol evenly, put it into the designed mold, hot press at a pressure of 2.0Mpa and a temperature of 140°C, hold the pressure for 10 minutes, and then cure at 160°C for 23 hours to obtain a density of 1.24g / cm 3 The carbon fiber reinforced green body (CFRP) has 36 cooling channels. The carbon fiber reinforced green body (CFRP) was carbonized for 60 hours under the protection of nitrogen at a pressure of 0.1Mpa and a maximum temperature of 600°C to obtain a ...

Embodiment 3

[0061] Using the PAN type XK-24-1 (24K) carbon fiber bundle produced by Dalian Xingke Carbon Fiber Co., Ltd., the carbon fiber bundle is passed through the liquid resin at a wire speed of 15mm / s, dried and cut to obtain a length of 30mm. Modified carbon fiber, the liquid resin is composed of liquid furan resin and liquid epoxy resin in a mass ratio of 1:1. The asphalt powder with an average particle size of 0.3mm, the silicon powder with a purity ≥ 99.5% and an average particle size of 50nm, short carbon fibers of 30mm and absolute ethanol by mass percentage: 24% carbon fiber, 7% silicon powder, 65 % asphalt powder and 4% absolute ethanol are evenly mixed, put into the designed mold, hot press at a pressure of 5.0Mpa and a temperature of 100°C, hold the pressure for 20min and then cure at 180°C for 22h to obtain the density 1.18g / cm 3 The carbon fiber reinforced green body (CFRP) has 32 cooling channels. The carbon fiber reinforced green body was carbonized under the protect...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com