Low-VOC high-performance PC/ABS alloy material and its preparation and application

A technology of alloy materials and raw materials, which is applied in the preparation of automotive interior parts, PC/ABS alloy materials and their preparation fields, can solve the problem of high total carbon emission of PC/ABS alloys, and achieve excellent mechanical properties, good odor, and organic volatiles The effect of less content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

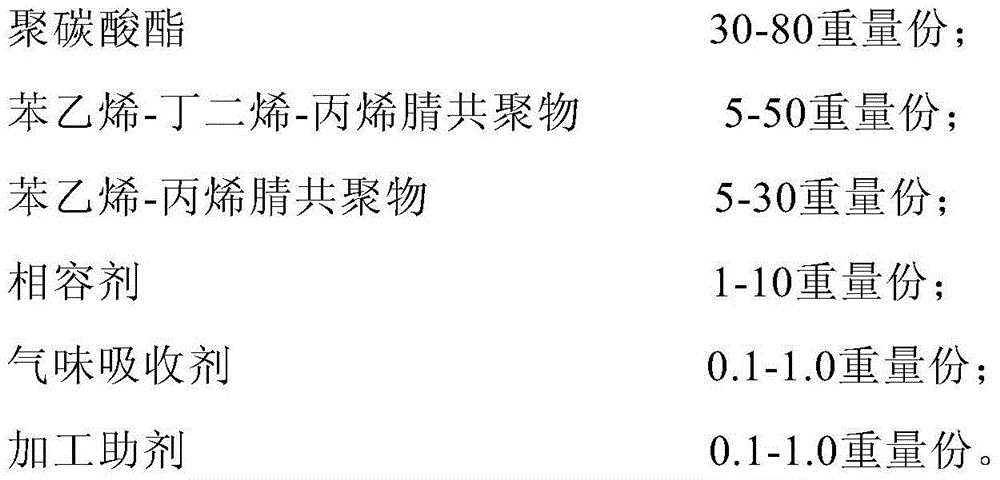

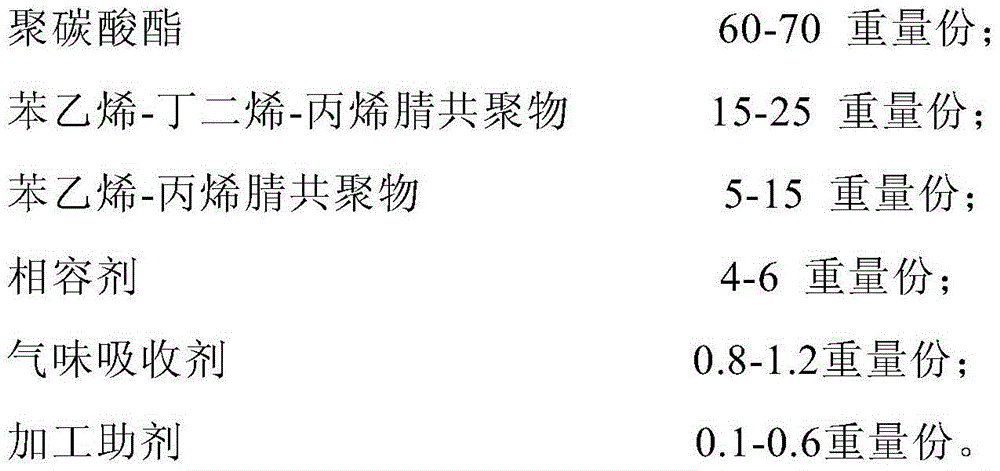

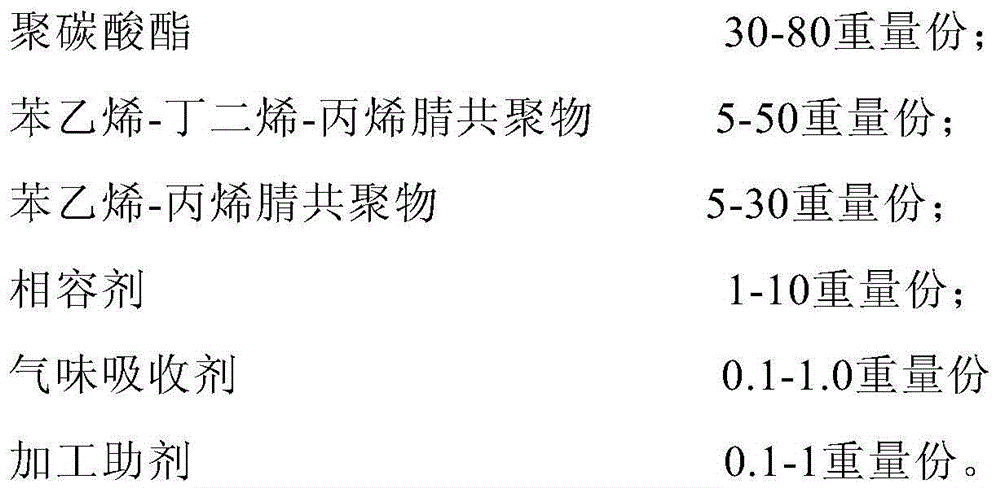

Method used

Image

Examples

Embodiment 1~5

[0050] The parts by weight of each raw material are shown in Table 1.

[0051]Add PC resin, ABS resin, and various additives to a high-speed mixer and stir at high speed for 2 minutes, then add them to the main feeder of the extruder, and then add them to the twin-screw extruder for basic granulation. The temperature distribution of the extruder is as follows: from the feed section to the head: 240°C, 260°C, 260°C, 260°C, 255°C, 250°C, 250°C, 250°C, 250°C, die head: 260°C , After the material is extruded, it is water-cooled, pelletized, and then packaged. The pellets were dried in a blast oven at 90°C for 4 hours, and then test specimens were prepared by an injection molding machine.

[0052] Table 1 raw material parts by weight proportioning table

[0053]

[0054] Processing aid: 0.1 parts by weight of primary antioxidant 1010 (tetrakis [β-(3,5-di-tert-butyl-4-hydroxyphenyl) propionic acid] pentaerythritol ester), 0.2 parts by weight of auxiliary antioxidant 168 (three ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com