A kind of preparation method of two-component condensation type room temperature vulcanization silicone rubber curing agent

A room temperature vulcanization and condensation type technology, applied in the direction of tin organic compounds, etc., can solve the problems of low stability and high organic tin content, and achieve the effects of small performance changes, high stability, and changing operation and vulcanization time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

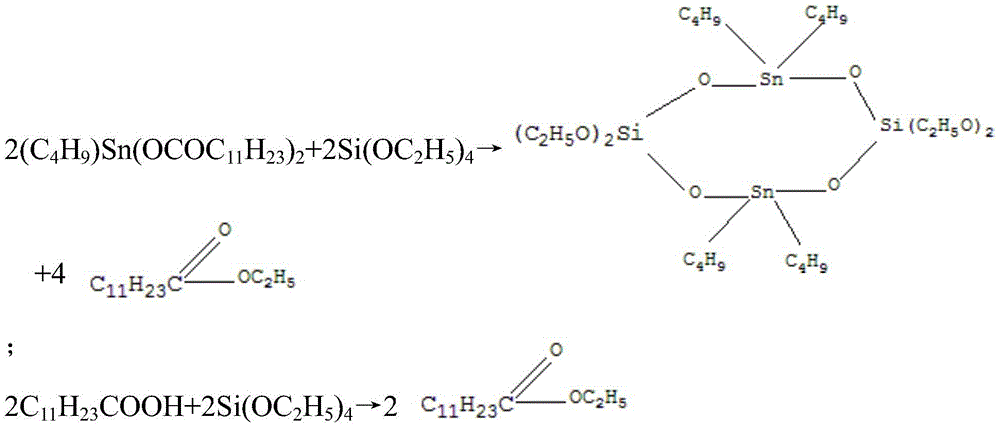

Method used

Image

Examples

Embodiment 1

[0022] According to the method disclosed in the present invention, the inventor has carried out the following operations:

[0023] Mix ethyl orthosilicate and dibutyltin laurate in a weight ratio of 6:1, wherein, ethyl orthosilicate is 360g, dibutyltin dilaurate is 60g, and macroporous strong acid cations are added Exchange resin 70g, react for 15min, add 3g of water to continue the reaction for 1.5h, and obtain the finished product 1.

Embodiment 2

[0025] Add 0.5% tetraisopropyl titanate to finished product 1 to obtain finished product 2.

Embodiment 3

[0027] With the following raw materials: tetraethyl orthosilicate 490g, dibutyltin dilaurate 62g, methyltrimethoxysilane 85g, pure water 3g, macroporous strong acid cation exchange resin 75g is prepared according to the method in embodiment 1, obtains Finished product3.

[0028] The inventor made the finished product 1 made in August, and the operation time was 61 minutes when doing the vulcanization experiment, and stored it until February of the next year (the temperature was slightly lower than August) to continue the vulcanization experiment, and the operation time was 67 minutes, almost the same as before. At the same time, the vulcanization time is about 5 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com