Hot-press adhesive tape

A technology of tape and hot-melt adhesive layer, which is applied in the field of hot-pressed adhesive tape, can solve the problems of capacitor residue and easy degumming, and achieve the effects of good retention, good toughness, and high tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

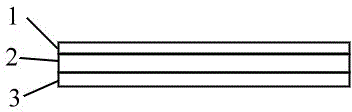

[0034] like figure 1 As shown, the heat-pressing adhesive tape provided by the present invention includes a PET film layer 1 , a first hot-melt adhesive layer 2 , and a second hot-melt adhesive layer 3 from top to bottom. The formula of the first hot-melt adhesive layer is: 40 parts of ethylene-vinyl acetate copolymer, its vinyl acetate monomer content is 10%, and its MI value is 380; 60 parts of saturated polyester resin; four (3,5 -0.4 parts of pentaerythritol di-tert-butyl-4-hydroxy)phenylpropionate. The formula of the second hot-melt adhesive layer is: 79 parts of ethylene-vinyl acetate copolymer, the content of vinyl acetate monomer is 28%, and its MI value is 35; 10 parts of petroleum resin; 10 parts of paraffin; four (3, 1 part of pentaerythritol 5-di-tert-butyl-4-hydroxy)phenylpropionate. The thickness of the PET film layer is 50 μm; the thickness of the first hot melt adhesive layer is 10 μm; the thickness of the second hot melt adhesive layer is 20 μm. After the h...

Embodiment 2

[0036] like figure 1 As shown, the heat-pressing adhesive tape provided by the present invention includes a PET film layer 1 , a first hot-melt adhesive layer 2 , and a second hot-melt adhesive layer 3 from top to bottom. The formula of the first hot-melt adhesive layer is: 48 parts of ethylene-vinyl acetate copolymer, its vinyl acetate monomer content is 10%, and its MI value is 380; 67 parts of saturated polyester resin; four (3,5 -1 part of pentaerythritol di-tert-butyl-4-hydroxy)phenylpropionate. The formula of the second hot-melt adhesive layer is: 89 parts of ethylene-vinyl acetate copolymer, the content of vinyl acetate monomer is 28%, and its MI value is 35; 5 parts of petroleum resin; 15 parts of paraffin; four (3, 2 parts of pentaerythritol 5-di-tert-butyl-4-hydroxy)phenylpropionate. The thickness of the PET film layer is 45 μm; the thickness of the first hot melt adhesive layer is 12 μm; the thickness of the second hot melt adhesive layer is 25 μm. After the heat...

Embodiment 3

[0038] like figure 1 As shown, the heat-pressing adhesive tape provided by the present invention includes a PET film layer 1 , a first hot-melt adhesive layer 2 , and a second hot-melt adhesive layer 3 from top to bottom. The formula of the first hot-melt adhesive layer is: 27 parts of ethylene-vinyl acetate copolymer, its vinyl acetate monomer content is 10%, and its MI value is 380; 48 parts of saturated polyester resin; four (3,5 -0.5 parts of pentaerythritol di-tert-butyl-4-hydroxy)phenylpropionate. The formula of the second hot-melt adhesive layer is: 70 parts of ethylene-vinyl acetate copolymer, the content of vinyl acetate monomer is 28%, and its MI value is 35; 12 parts of petroleum resin; 6 parts of paraffin; four (3, 0.7 parts of pentaerythritol 5-di-tert-butyl-4-hydroxy)phenylpropionate. The thickness of the PET film layer is 53 μm; the thickness of the first hot melt adhesive layer is 9 μm; the thickness of the second hot melt adhesive layer is 18 μm. After the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com