Oilfield on-site production method of oil-displacement microbial inoculum

A technology for oil-displacing microorganisms and a production method, which is applied in the field of microbial oil-displacing bacterial agent production, and can solve the problems of affecting the oil-displacing effect of microbial composition and reducing the proportion of the oil.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

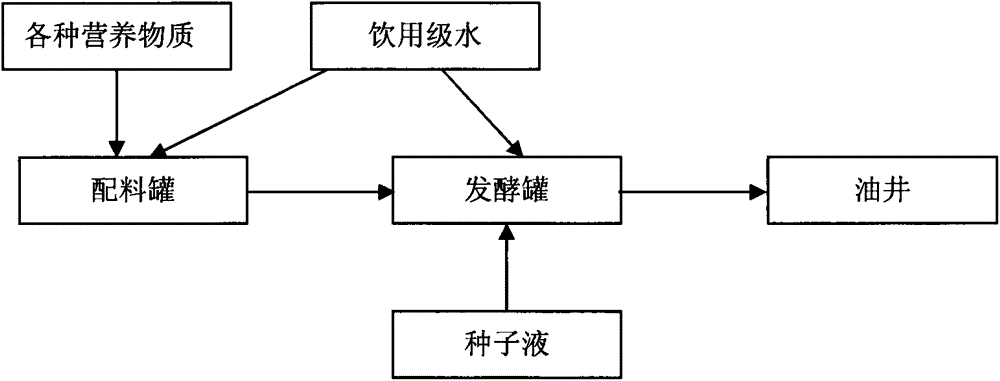

Method used

Image

Examples

Embodiment 1

[0017] 1). The Pseudomonas aeruginosa bacterial strain is produced in the factory to obtain 300L of seed solution, which is transported to the oilfield site.

[0018] 2). The fermentation medium of Pseudomonas aeruginosa is: molasses 7g / L, yeast extract 2g / L, fish meal 3g / L, NaNO 3 10g / L, K 2 HPO 4 0.4g / L, MgSO 4 ·6H 2 O0.2g / L. In the batching tank, molasses 42kg, yeast paste 12kg, fish meal 18kg, NaNO 3 60kg,K 2 HPO 4 2.4kg, MgSO 4 ·6H 2 O1.2kg, add 1.2 tons of drinking-grade tap water or underground water, and heat to 100°C for 10min, then transfer to the fermenter by pump.

[0019] 3). Add drinking-grade tap water or underground water into the fermenter and dilute to a total volume of 5.7 tons of the culture medium, and at the same time adjust the pH to 7.0 with the acid-base solution.

[0020] 4). Inoculate the high-activity seed liquid produced by the factory, the inoculum amount of the seed liquid is 5% (V / V) of the total volume of the fermentation liquid, that...

Embodiment 2

[0023] 1). The Bacillus subtilis strain is produced in the factory to obtain 1.2 tons of seed liquid, which is transported to the oilfield site.

[0024] 2). The fermentation medium of Bacillus subtilis is: sucrose 5g / L, peptone 4g / L, corn steep liquor 1g / L, NH 4 Cl7g / L, KH 2 PO 4 1g / L, MgSO 4 ·6H 2 O0.3g / L, CaCl 2 0.1g / L. In the batching tank, 30kg of sucrose, 24kg of peptone, 6kg of corn steep liquor, NH 4 Cl42kg, KH 2 PO 4 6kg, MgSO 4 ·6H 2 O1.8kg, CaCl 2 0.6kg, add 300L of drinking-grade tap water or underground water, and heat to 85°C for 30min, then transfer to the fermenter by pump.

[0025] 3). Add drinking-grade tap water or underground water into the fermenter to dilute the total volume of the culture medium to 4.8 tons, and at the same time adjust the pH to 7.4 with the acid and alkali solution.

[0026] 4). Inoculate the high-energy seed liquid produced by the factory, the inoculum amount of the seed liquid is 20% (V / V) of the total volume of the fermen...

Embodiment 3

[0029] 1). Each of Pseudomonas aeruginosa and Bacillus subtilis strains was produced in the factory to obtain 0.3 tons of seed liquid, and transported to the oilfield site.

[0030] 2). The suitable fermentation medium is molasses 7g / L, yeast extract 2g / L, fish meal 3g / L, NaNO 3 10g / L, K 2 HPO 4 0.4g / L, MgSO 4 ·6H 2 O0.2g / L. In the batching tank, molasses 42kg, yeast paste 12kg, fish meal 18kg, NaNO 3 60kg,K 2 HPO 4 2.4kg, MgSO 4 ·6H 2 O1.2kg, add 0.8 tons of drinking-grade tap water or underground water, and heat to 90°C for 20min, then transfer to the fermenter by pump.

[0031]3). Add drinking-grade tap water or underground water into the fermenter and dilute to a total volume of 5.4 tons of the culture medium, and at the same time adjust the pH to 7.4 with the acid-base solution.

[0032] 4). Inoculate the high-energy seed liquid produced by the factory, the inoculum amount of the seed liquid is 10% (V / V) of the total volume of the fermentation liquid, that is, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com