Strengthened steel pipe with rib spirally wound as well as special equipment and method for manufacturing preparing strengthened steel pipe

A technology of spiral winding and special equipment, applied in the field of pipelines, can solve the problems of heavy weight, difficult installation and material waste of steel pipelines, and achieve the effect of improving strength, satisfying anti-corrosion performance and saving material resources.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

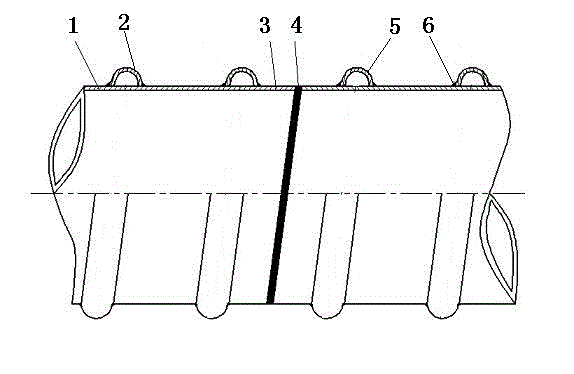

[0039] The structure of the helically wound rib-reinforced steel pipe provided by the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0040] Such as figure 1 As shown, a spirally wound steel pipe provided by the present invention includes a pipe body 1, the outer wall of the pipe body 1 is spirally wound and welded with structural wall reinforcing ribs 2, and the pipe body 1 is composed of a large steel strip 3 that is spirally rolled and welded and a spiral welded steel strip 3. The structural wall reinforcement 2 is composed of a small steel strip 5 that is rolled and formed into the shape of the structural wall and then spirally wound. There is a welding node 6 between the small steel strip 5 and the pipe body 1 .

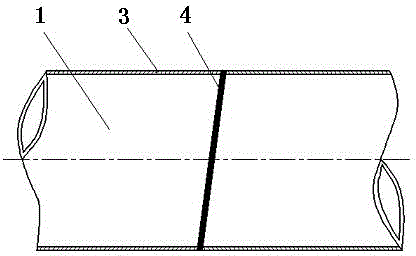

[0041] Such as figure 2 As shown, the pipe body 1 consists of a helically wound steel strip 3 and a helical weld 4 .

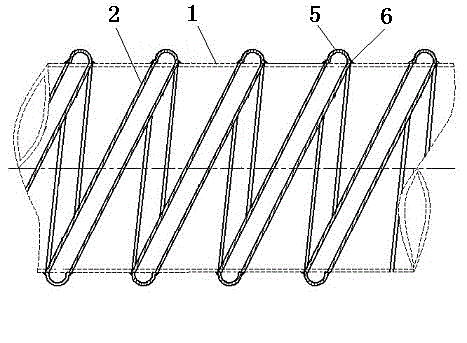

[0042] Such as image 3 As shown, the structural wall reinforcement 2 is comp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com