A kind of flip-chip nano LED chip and preparation method thereof

A LED chip and nanotechnology, applied in semiconductor devices, electrical components, circuits, etc., can solve the problems of ineffective independent electroluminescence, difficult to effectively control the position and size of nanopillars, and leakage, so as to improve light extraction efficiency and reliability , Uniform current expansion, and the effect of reducing leakage current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

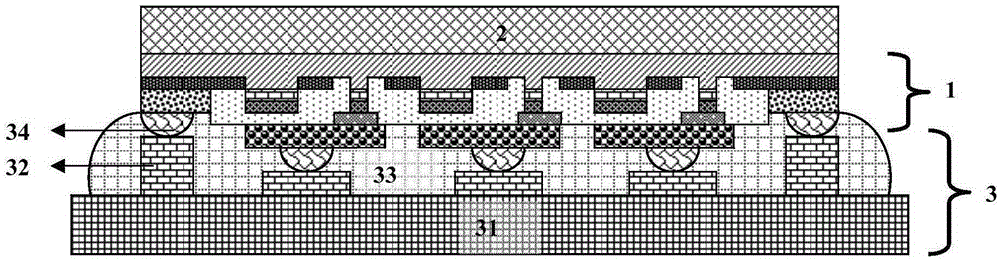

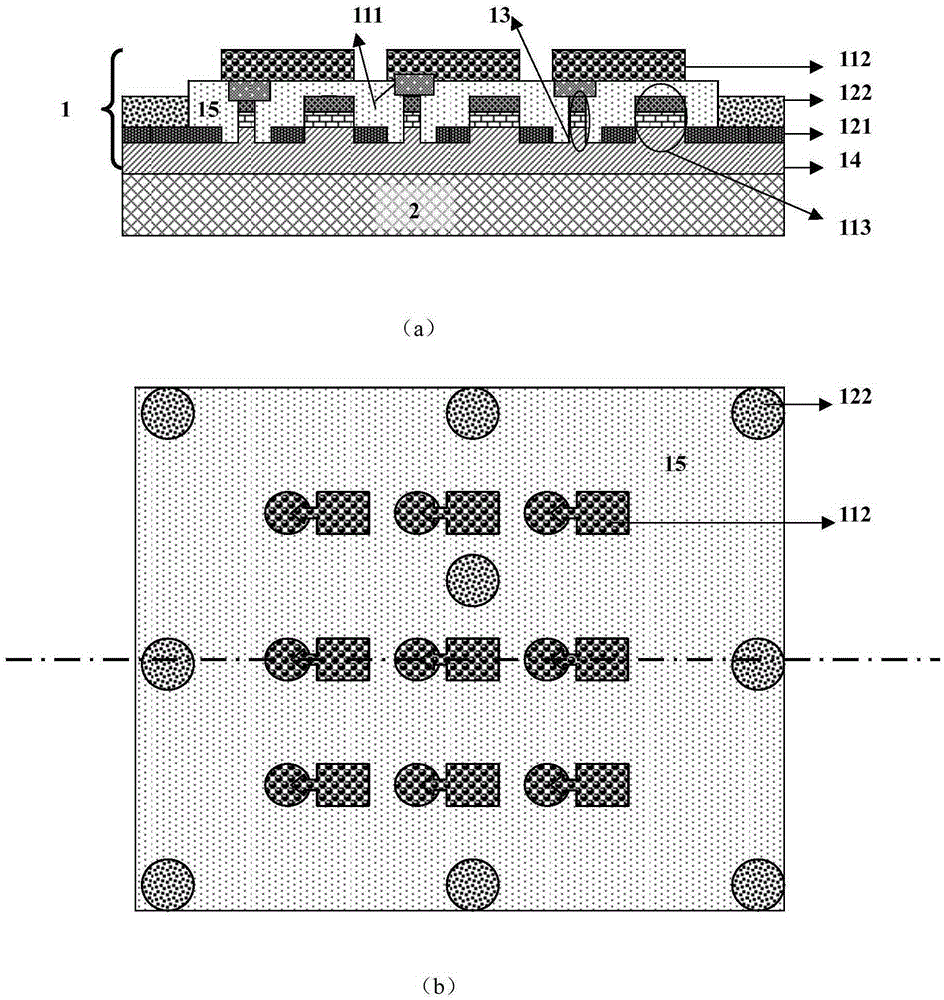

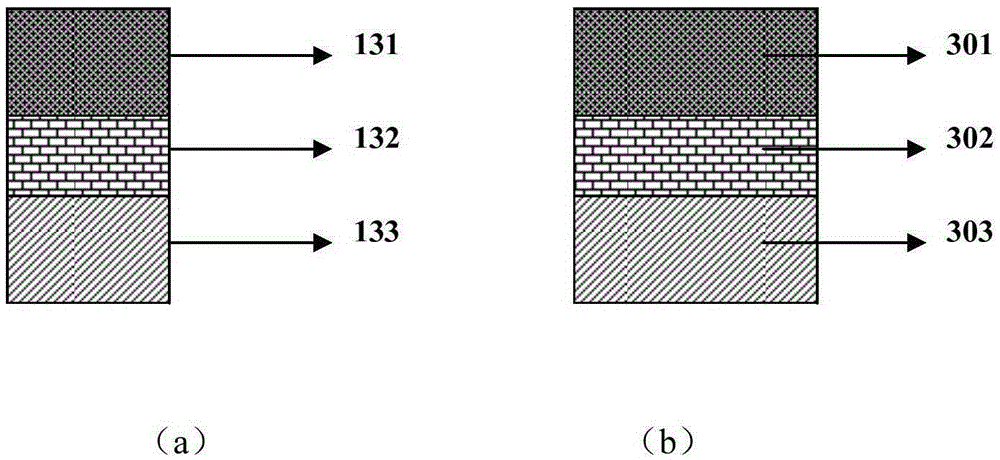

[0047] like figure 1 As shown, the flip-chip nano-LED chip of this embodiment includes: an epitaxial chip part 1, a substrate 2 and a flip-chip soldering part 3; the epitaxial chip part 1 is located on the substrate 2 and includes a p-type contact layer, an n-type contact layer, Nano column array 13, unetched n-type layer 14 and passivation layer 15; P-type contact layer includes p-electrode layer 111, p-pad layer 112 and P-electrode pad platform 113; n-type contact layer includes n-electrode layer 121 And n pad layer 122; Wherein, nanocolumn array 13 is distributed on unetched n-type layer 14; Discrete P electrode pad platform 113 is distributed on unetched n-type layer 14; Nanocolumn array 13 and discrete The p-electrode pads 113 are arranged in a staggered manner; the discrete p-electrode layer 111 corresponds to the nano-pillar array 13 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com