Production technology of green Chinese prickly ash numb-taste components

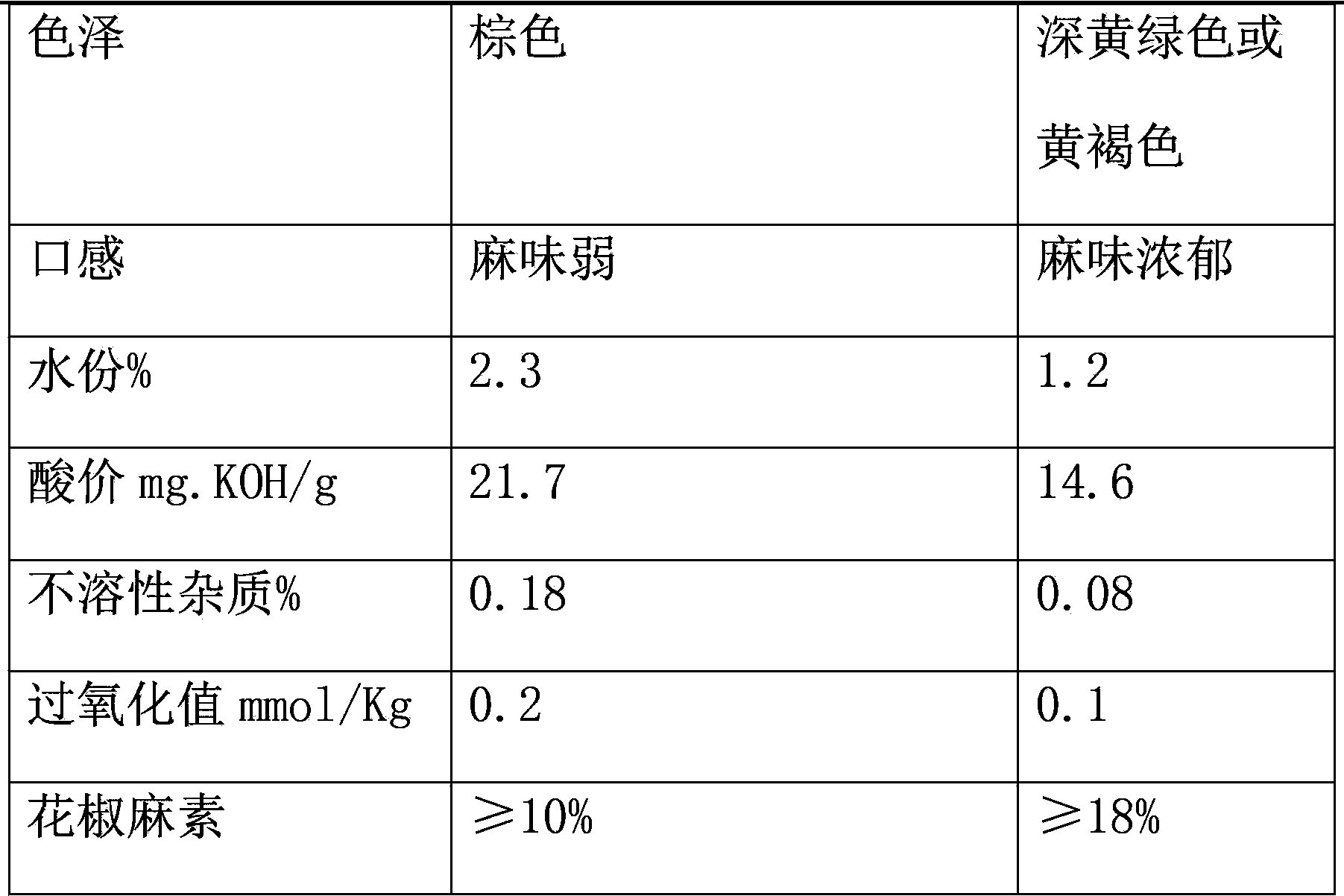

A production process, the technology of green Zanthoxylum bungeanum, applied in the field of production technology of green Zanthoxylum bungeanum, can solve the problems of limited dissolving capacity of supercritical carbon dioxide extraction, long extraction time, low extraction rate of Zanthoxylum bungeanum, etc., and achieve the quality of extracted products High, high extraction efficiency, the effect of improving the extraction rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A kind of production technology of green zanthoxylum bungeanum, comprises the following steps:

[0021] a. Separating the dehydrated green pepper by specific gravity, removing impurities, and separating to obtain clean pepper skin, which is set aside;

[0022] b. Put the materials in step a and edible ethanol into the ultrasonic extraction reaction tank according to the weight ratio of 1:2, open the vacuum valve of the extraction tank, press the function key of ultrasonic extraction, and enter the extraction state at this time, and the temperature is controlled at 60°C. At the same time, the extraction internal circulation function is turned on to achieve the effect of stirring. The extraction time lasts for 90 minutes. After the extraction is completed, the material is finely filtered for later use.

[0023] c. Put the material obtained in step b into the ultrasonic extraction reaction concentration tank, open the extraction and concentration key and vacuum valve on th...

Embodiment 2

[0025] A kind of production technology of green zanthoxylum bungeanum, comprises the following steps:

[0026] a. Separating the dehydrated green pepper by specific gravity, removing impurities, and separating to obtain clean pepper skin, which is set aside;

[0027] b. Put the materials in step a and edible ethanol into the ultrasonic extraction reaction tank according to the weight ratio of 1:3, open the vacuum valve of the extraction tank, press the function key of ultrasonic extraction, and enter the extraction state at this time, and the temperature is controlled at 80°C. At the same time, the internal circulation function of the extraction is turned on to achieve the effect of stirring. The extraction time lasts for 60 minutes. After the extraction is completed, the material is finely filtered for later use.

[0028] c. Put the material obtained in step b into the ultrasonic extraction reaction concentration tank, open the extraction and concentration key and vacuum valv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com