Preparation method of magnetic bentonite for removing MC-LR (microcystic toxins)

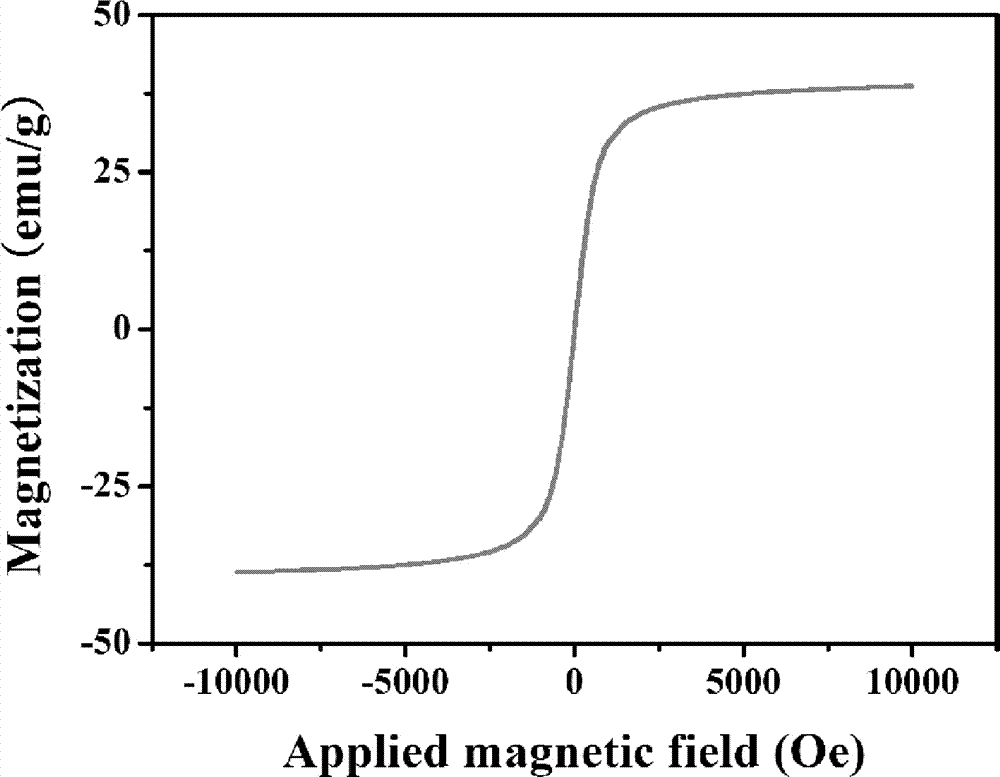

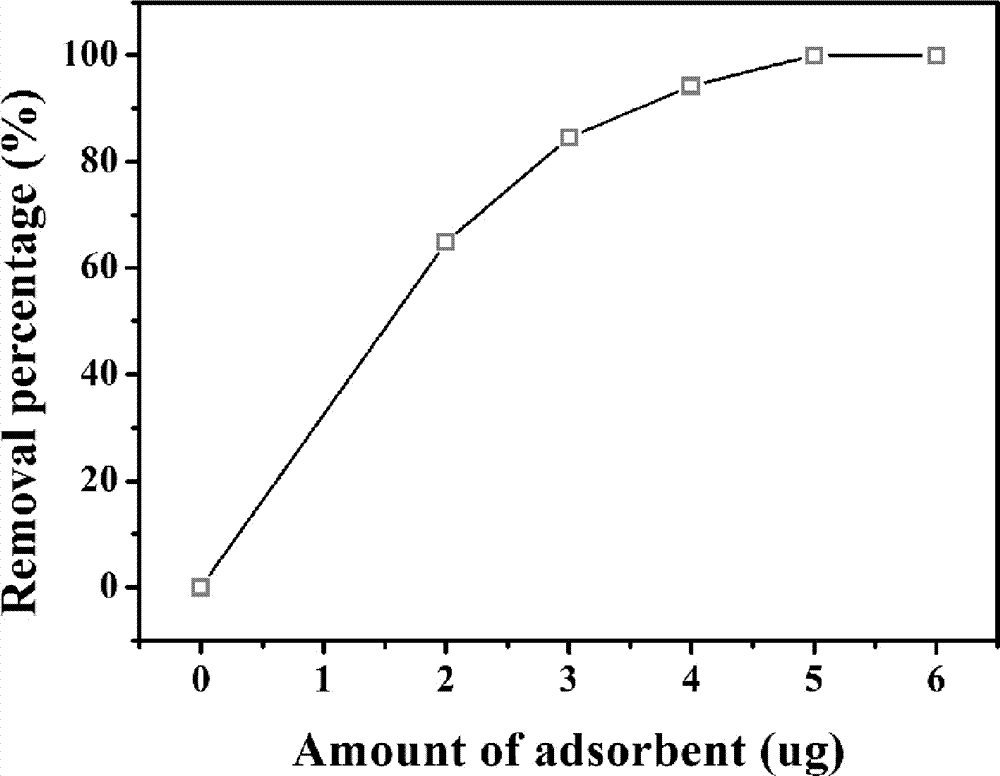

A technology of MC-LR and bentonite, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of weak adsorption capacity and low magnetism of composite materials, and achieve strong enrichment capacity, Synthesize simple, magnetic effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0015] The preparation embodiment of magnetic bentonite:

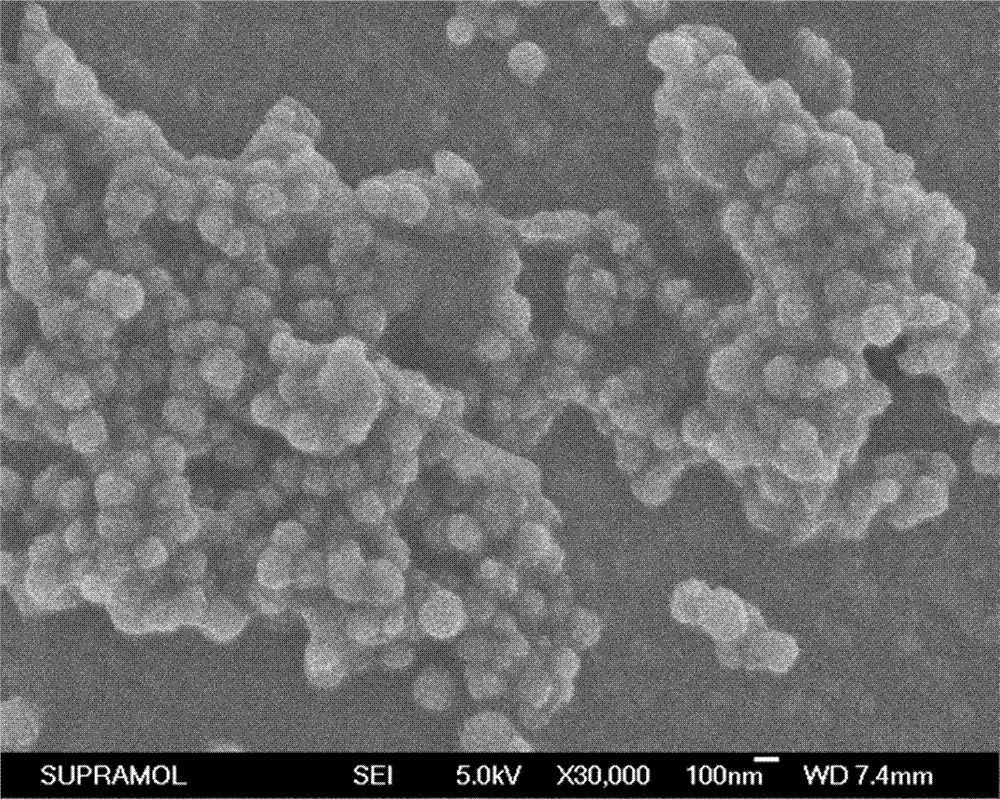

[0016] Weigh 0.5 g of zirconium pillared bentonite, FeCl 3 ·6H 2 O (1.35 g) was dissolved in 40 mL of ethylene glycol and stirred magnetically for 10 min, after which anhydrous sodium acetate (3.60 g) and polyethylene glycol (1.00 g) were added. The mixture was stirred for 20 min to form a yellow-brown liquid, which was transferred to a polytetrafluoroethylene-lined stainless steel reactor (50 mL) and sealed, and heated to 190 °C in an oven for 8 h. The obtained magnetic bentonite was separated by an external magnetic field, washed several times with secondary water and absolute ethanol, then vacuum-dried at 60 °C for 6 h, and ground to obtain the finished Zr-B-Fe 3 o 4 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com