Olefin isomerization catalyst and preparation method thereof

A technology for olefin isomerization and catalysts, which is applied in the field of olefin isomerization catalysts and its preparation, can solve problems such as the complexity of the reaction process, and achieve the effects of increased yield, easy control, and simple preparation methods

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

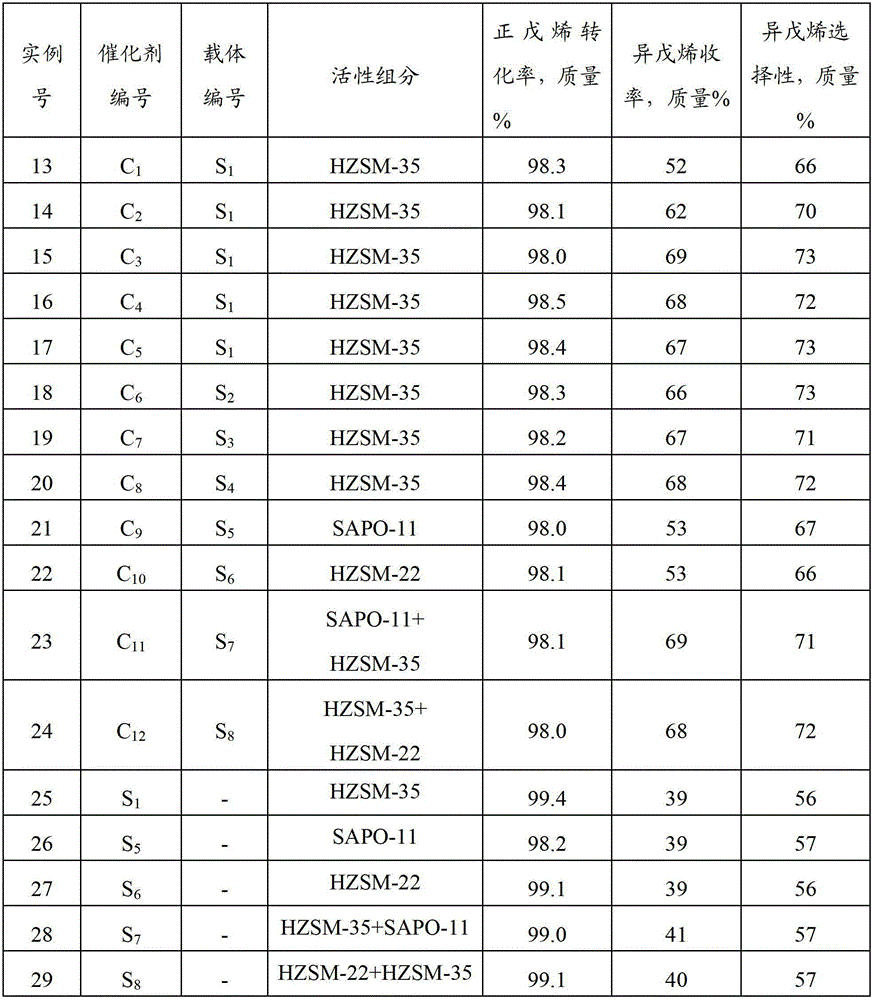

Examples

preparation example Construction

[0014] The preparation method of the catalyst provided by the present invention includes mixing molecular sieves and binders, drying and roasting to obtain a carrier, and then impregnating with an aqueous solution of a modified compound. dry.

[0015] The molecular sieve is preferably one or any two of ZSM-35, ZSM-22 and SAPO-11, and the binder is preferably alumina.

[0016] The method of mixing molecular sieve and binder in the method of the present invention is extruding, dropping ball, rolling ball or tableting method, preferably extruding. The extruding method is as follows: uniformly mix the molecular sieve with the binder or its precursor, add an appropriate amount of extrusion aid and / or peptizer and knead, and then extrude. The extrusion aid is preferably squash powder, and the peptizing agent is preferably an inorganic acid, such as hydrochloric acid or nitric acid. After the wet strip is cut into pellets, the carrier is obtained by drying and roasting. The temper...

example 1

[0027] Mix 10788 grams of HZSM-35 molecular sieve with a molar ratio of silica to alumina of 25 and 1637.8 grams of pseudoboehmite, add 65.5 grams of nitric acid with a concentration of 65% by mass and 10770 grams of water, and extrude with a twin-screw extruder The trefoil strips with a diameter of 1.1 mm were cut into pellets, dried at 120°C for 4 hours, and calcined at 550°C for 2 hours to obtain the carrier S 1 , wherein the content of HZSM-35 molecular sieve is 90% by mass, and the content of alumina is 10% by mass.

[0028] Take 2000 grams of carrier S 1 , impregnated with 1939 ml of an aqueous solution containing 146.2 grams (0.601 mol) of triammonium citrate at 25 ° C for 0.5 hours, and then dried at 90 ° C and 0.01 MPa for 2 hours to obtain catalyst C 1 , whose weight is 2145.1 g, indicating that the catalyst C 1 Contains 145.1 grams of triammonium citrate, ammonium salt and carrier S 1 The mass ratio is 0.073.

example 2

[0030] Take 2000 grams of carrier S 1 , impregnated with 1939 ml of an aqueous solution containing 251.6 g (1.497 mol) of ammonium malate at 25 ° C for 0.5 hours, and then dried at 90 ° C and 0.01 MPa for 2 hours to obtain catalyst C 2 , whose weight is 2250.8 g, indicating that the catalyst C 2 Contains 250.8 grams of ammonium malate, which contains ammonium salt and carrier S 1 The mass ratio is 0.125.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com