A method for recycling reclaimed water to a circulating cooling water system

A technology for circulating cooling water and reclaimed water, applied in chemical instruments and methods, water/sludge/sewage treatment, descaling and water softening, etc., can solve problems such as pipeline corrosion, achieve corrosion inhibition, ensure safety, reduce rich The effect of nutritional risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

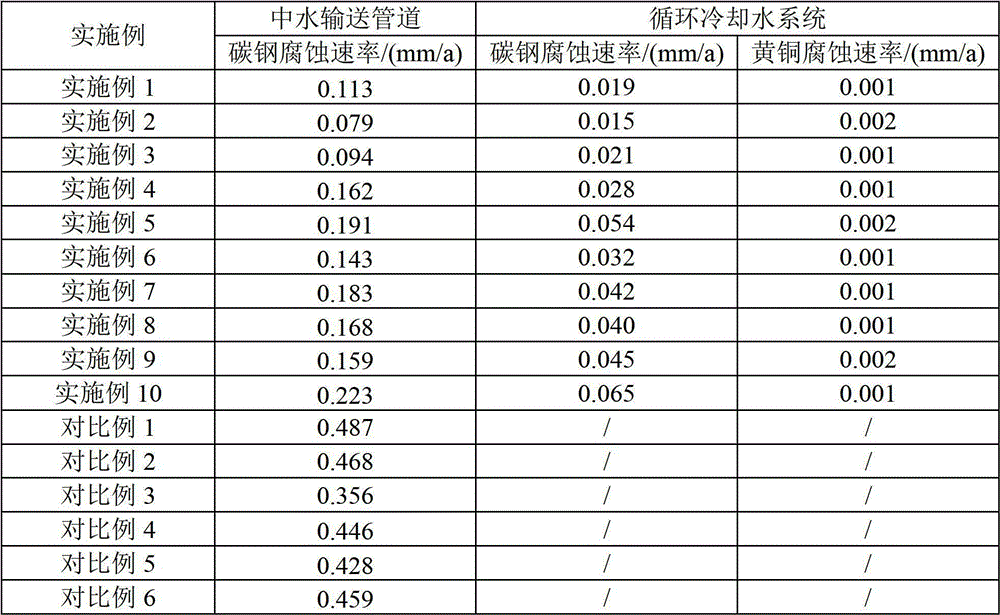

Embodiment 1

[0040] Take 1# middle water as test water, add dihydrate sodium molybdate and tolyl benzotriazole therein, make the dihydrate sodium molybdate (as MoO 4 2- The concentration is 15mg / L, and the concentration of tolyl benzotriazole is 3mg / L, so as to carry out the corrosion evaluation test of reclaimed water pipeline transportation. The above reclaimed water is concentrated 5 times under the condition of pH=8.1±0.1, and the reclaimed water added with the aforementioned corrosion inhibitor in the production site is simulated as the replenishment water of the recirculating cooling water and added to the recirculating cooling water in the recirculating cooling water system to obtain Simulate circulating cooling water. Add polyaspartic acid (limited viscosity at 30°C is 0.055dL / g) and acrylic acid-methyl acrylate-2-acrylamide-2-methylpropanesulfonic acid copolymer (weight ratio is 3:1:1 Acrylic acid monomer, methyl acrylate monomer and 2-acrylamide-2-methylpropanesulfonic acid mon...

Embodiment 2

[0042] Take 2# middle water as test water, add potassium molybdate and benzotriazole therein, make the potassium molybdate in middle water (as MoO 4 2- The concentration of benzotriazole is 20mg / L, and the concentration of benzotriazole is 1mg / L, so as to carry out the corrosion evaluation test of reclaimed water pipeline transportation. Concentrate the above-mentioned reclaimed water by 4 times under the condition of pH=8.6±0.1, and simulate the state where the reclaimed water added with the aforementioned corrosion inhibitor in the production site is added to the recirculating cooling water in the recirculating cooling water system as replenishment water of the recirculating cooling water to obtain Simulate circulating cooling water. Add polyepoxysuccinic acid (the limiting viscosity at 30°C is 0.042dL / g), acrylic acid-hydroxypropyl acrylate copolymer (a product obtained by copolymerization of acrylic acid monomer and hydroxypropyl acrylate monomer at a weight ratio of 3:1)...

Embodiment 3

[0044] Take 1# middle water as test water, add dihydrate sodium molybdate and tolyl benzotriazole therein, make the dihydrate sodium molybdate (as MoO 4 2- The concentration is 18mg / L, and the concentration of tolyl benzotriazole is 2mg / L, so as to carry out the corrosion evaluation test of reclaimed water pipeline transportation. Concentrate the above-mentioned reclaimed water by 2.5 times under the condition of natural pH value, and simulate the state where the reclaimed water added with the aforementioned corrosion inhibitor in the production site is added to the recirculating cooling water in the recirculating cooling water system as the supplementary water of the recirculating cooling water to obtain a simulated cycle Cooling water. Add polyepoxysuccinic acid (the limiting viscosity at 30°C is 0.060dL / g) and acrylic acid-ethyl acrylate copolymer (a product obtained by copolymerization of acrylic acid monomer and ethyl acrylate monomer with a weight ratio of 4:1, 30 The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com