A device and method for producing ethanol by catalytic hydrogenation of acetic acid or acetate

A technology for catalytic hydrogenation and acetate, applied in chemical instruments and methods, preparation of hydroxyl compounds, preparation of organic compounds, etc., can solve the problems of large hydrogen circulation, reducing the hydrogen-acid ratio of the system, low-level operation of acetic acid, etc., to achieve control The effect of bed temperature, reduction of hydrogen-acid ratio, and good technical economy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

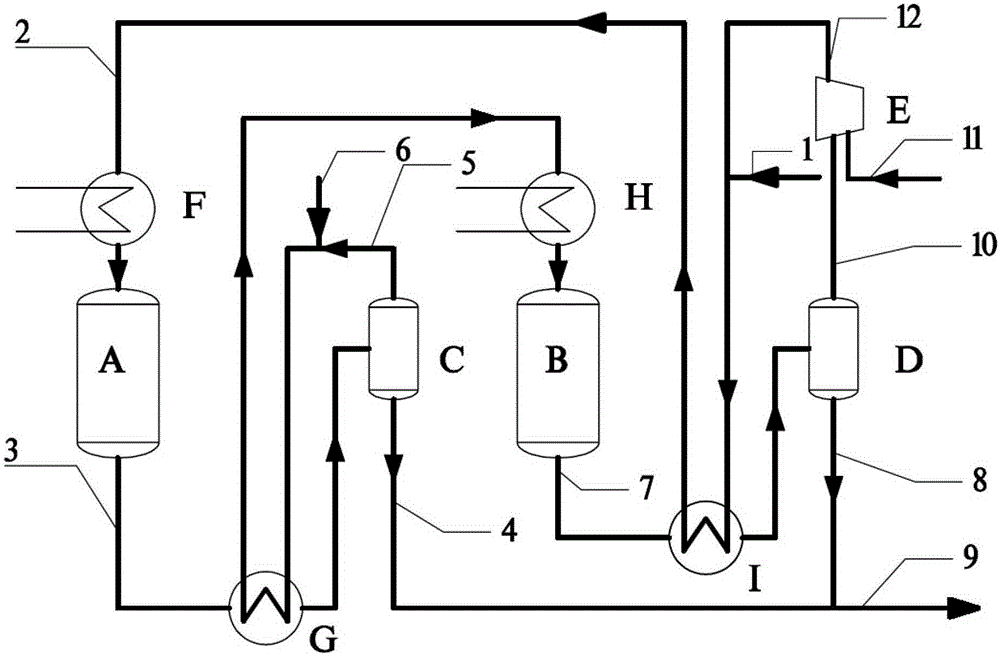

[0026] Such as figure 1 Shown: a device for producing ethanol by catalyzing hydrogenation reaction of acetic acid or acetate, including a first reactor A, a second reactor B, a first gas-liquid separator C, a second gas-liquid separator D, and circulating hydrogen gas Compressor E, first heater F, first heat exchanger G, second heater H, second heat exchanger I. The heater F is connected to the reactor A through a pipeline; the first reactor A is connected to the first heat exchanger G and the first gas-liquid separator C through a pipeline in turn, and the gas phase outlet of the first gas-liquid separator C is connected to the first gas-liquid separator C in sequence. A heat exchanger G and a second heater H; the outlet flow of the second heater H is connected to the second reactor B through a pipeline; the outlet pipeline of the second reactor B is connected to the second heat exchanger I and the second gas-liquid separation in sequence Device D; the gas phase outlet of th...

Embodiment 2

[0035] according to figure 1 Shown, adopt technological process of the present invention. The first reactor A and the second reactor B are continuous heat exchange shell and tube reactors. The reactors use saturated process water for heat exchange and by-product steam. The reactors are filled with platinum metal carrier composite catalysts of the same quality. . The feed is acetic acid and hydrogen with a purity of 99.8%, the inlet temperature of reactor A is 200°C, the reaction pressure is 1.5MPa, and the weight space velocity of acetic acid is 0.1h -1 , the molar ratio of hydrogen to acid is 100:1; the inlet temperature of reactor B is 200°C, the reaction pressure is 1.48MPa, and the weight space velocity of acetic acid is 0.1h -1 . The mass ratio of the two acetic acid feed materials is 1:1.

[0036] The test proves:

[0037] 1. The hydrogen-acid ratio of the whole reaction system is 50:1;

[0038] 2. The actual hydrogen-acid ratio of the first reactor A and the secon...

Embodiment 3

[0042] according to figure 1 As shown, adopting the technological process of the present invention, the first reactor A is a layered fixed-bed reactor; the second reactor B is a continuous heat exchange tubular reactor, and the heat exchange medium of the second reactor B is heat transfer oil, Both the first reactor A and the second reactor B are filled with the same platinum-containing metal carrier composite catalyst, and the mass ratio of the catalyst bed filled catalyst in the first reactor A and the second reactor B is 1:1.2. The feed was acetic acid and hydrogen with a purity of 99.8%. The inlet temperature of reactor A is 350°C, the reaction pressure is 3.0MPa, and the weight space velocity of acetic acid is 0.7h -1 , the molar ratio of hydrogen to acid is 20:1; the inlet temperature of reactor B is 350°C, the reaction pressure is 2.98MPa, and the weight space velocity of acetic acid is 0.7h -1 . The mass ratio of two acetic acid feed materials is 1: 1.2

[0043] Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com