A kind of inorganic montmorillonite composite cross-linked polymer microsphere and its preparation method and application

A technology of cross-linked polymers and inorganic montmorillonite, applied in the direction of drilling compositions, chemical instruments and methods, etc., can solve the problems of high cost, achieve good expansion, good strength and water absorption, and high plugging strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

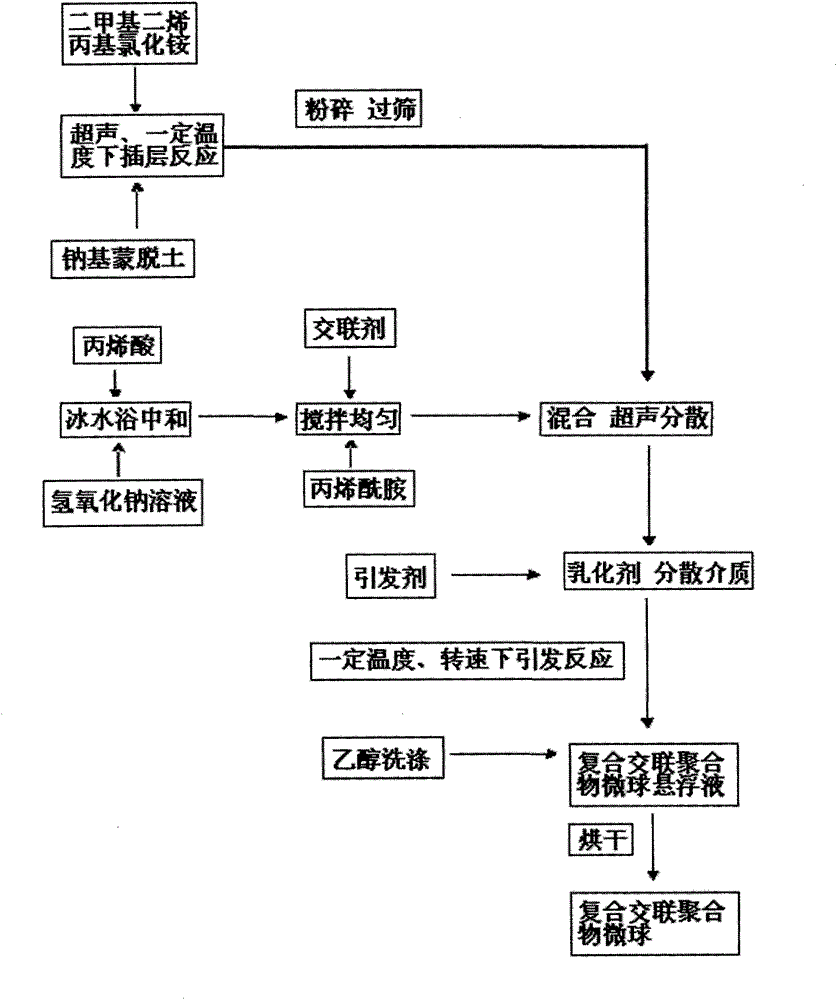

Method used

Image

Examples

Embodiment 1

[0027] The cross-linked polymer microspheres are further described below in conjunction with the examples.

[0028] Example 1

[0029] (1) Add 15g of montmorillonite to 15ml of water, stir for 50min, add 5ml of dimethyl diallyl ammonium chloride to 20ml of water, heat to 60°C, stir ultrasonically for 5h, filter the reactant with suction, and wash with hot ethanol aqueous solution Washing, filtering, washing until there is no chloride ion, drying the obtained product in a vacuum oven at 65°C to obtain a composite monomer of inorganic montmorillonite and dimethyl diallyl ammonium chloride, and crushing through a 200-mesh sieve ;

[0030] (2) Add 100g of cyclohexane and 3.0g of emulsifying dispersant into the reaction vessel, heat to 60°C, and stir for 30min;

[0031] (3) After neutralizing 14g of acrylic acid and 25% NaOH20ml in an ice-water bath, add 10g of acrylamide, 0.04g of crosslinking agent MBA, and 0.2g of crushed and sieved composite monomer, and ultrasonically disper...

Embodiment 2

[0036] (1) Add 15g of montmorillonite to 15ml of water, stir for 30min, add 5ml of dimethyl diallyl ammonium chloride to 20ml of water, heat to 70°C, stir ultrasonically for 3h, filter the reactant with hot ethanol Wash and filter the aqueous solution until there is no chloride ion, and dry the obtained product in a vacuum oven at 65°C to obtain a composite monomer of inorganic montmorillonite and dimethyl diallyl ammonium chloride, which is crushed through 200 mesh screen

[0037] (2) Add 100g of white oil and 4.0g of emulsifying dispersant into the reaction vessel, heat to 60°C, and stir for 60min.

[0038] (3) Neutralize 14g of acrylic acid and 25% NaOH in 22ml of ice-water bath, add 20g of acrylamide, 0.08g of cross-linking agent MBA, 1g of crushed and sieved composite monomer, and ultrasonically disperse for 60 minutes;

[0039] (4) After mixing (2) and (3), add 0.2g KPS-NaHS03, 0.02gAIBN, react for 3h;

[0040] (5) After the reaction is finished, the product is washed ...

Embodiment 3

[0043] (1) Add 15g of montmorillonite to 15ml of water, stir for 30min, add 5ml of dimethyl diallyl ammonium chloride to 20ml of water, heat to 80°C, stir ultrasonically for 4h, filter the reactant with suction, and wash with hot ethanol aqueous solution Washing, filtering, washing until there is no chloride ion, drying the obtained product in a vacuum oven at 65°C to obtain a composite monomer of inorganic montmorillonite and dimethyl diallyl ammonium chloride, and crushing through a 200-mesh sieve

[0044](2) Add 100g of cyclohexane and 7.0g of emulsifying dispersant into the reaction vessel, heat to 60°C, and stir for 30min;

[0045] (3) Neutralize 14g of acrylic acid and 25% NaOH in 24ml of ice-water bath, then add 20g of acrylamide, 0.12g of MBA, 2g of crushed and sieved composite monomer, and ultrasonically disperse for 60min;

[0046] (4) After mixing (2) and (3), add 0.1g KPS-NaHS03, 0.1g AIBN, and react with nitrogen for 5h;

[0047] (5) After the reaction is finishe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com