Insulation engineering plastic with high heat-conducting property and preparation method thereof

A technology of insulation engineering and high thermal conductivity, which is applied in the field of polymer composite materials, can solve the problems of heat dissipation of electronic equipment, reduce mechanical properties and insulation performance, and cannot meet high thermal conductivity, high flame retardancy, etc., and achieve quality Lightweight, reduced manufacturing cost, and low density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0059] The preparation method of the present invention comprises the following steps:

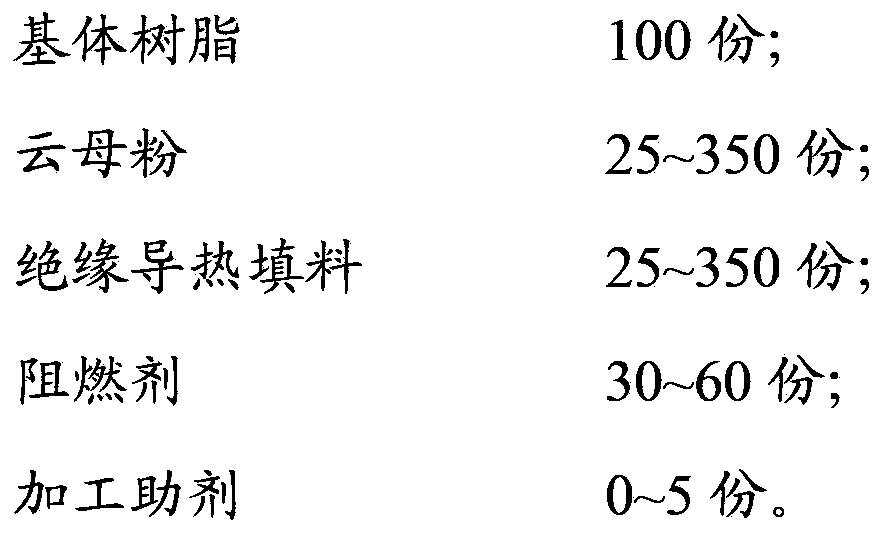

[0060] Step 1: Take the following components in parts by weight: 100 parts of matrix resin, 25-350 parts of mica powder, 25-350 parts of insulating and thermally conductive filler, 30-60 parts of flame retardant and 0-5 parts of processing aid;

[0061] Step 2: Add the matrix resin and processing aids into the mixer, and keep stirring for 3 to 8 minutes;

[0062] Step 3: Add mica powder and additives to the mixer, and keep stirring for 3 to 6 minutes;

[0063] Step 4: Add flame retardant to the mixer and keep stirring for 2 to 4 minutes;

[0064] Step 5: Add the mixture and insulating and heat-conducting filler into the main feeding and side feeding hoppers of the extruder respectively, extrude and granulate, and inject to form, so as to obtain the insulating engineering plastic with high heat-conducting performance.

[0065] Preferably, the insulating and thermally conductive filler is a...

Embodiment 1

[0069] An insulating engineering plastic with high thermal conductivity is prepared by the following method: add PA6 resin and aminosilane coupling agent to a mixer, and stir for 5 minutes; then add mica powder and other processing aids to the mixer, and continue to stir for 5 minutes; Then add the flame retardant to the mixer and stir for 3 minutes; add the mixture to the main feeding hopper of the twin-screw extruder, and add the insulating and thermally conductive filler magnesium oxide to the side feeding hopper of the twin-screw extruder; extrude and granulate, The temperature is set at 230°C-260°C to prepare insulating and heat-conducting PA6 engineering plastic particles, which are injected and molded to measure the performance of insulating engineering plastics.

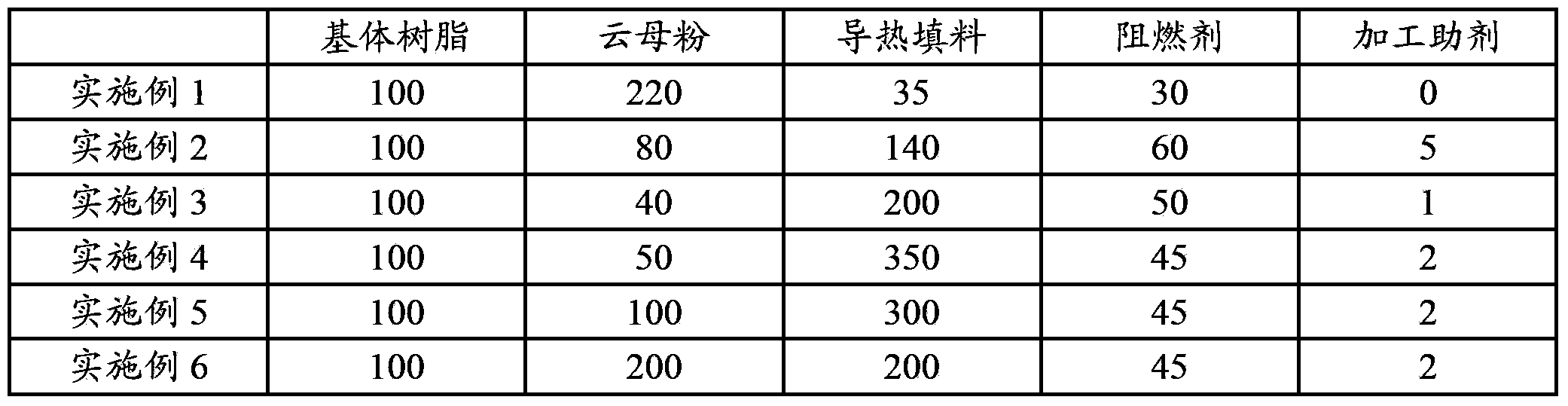

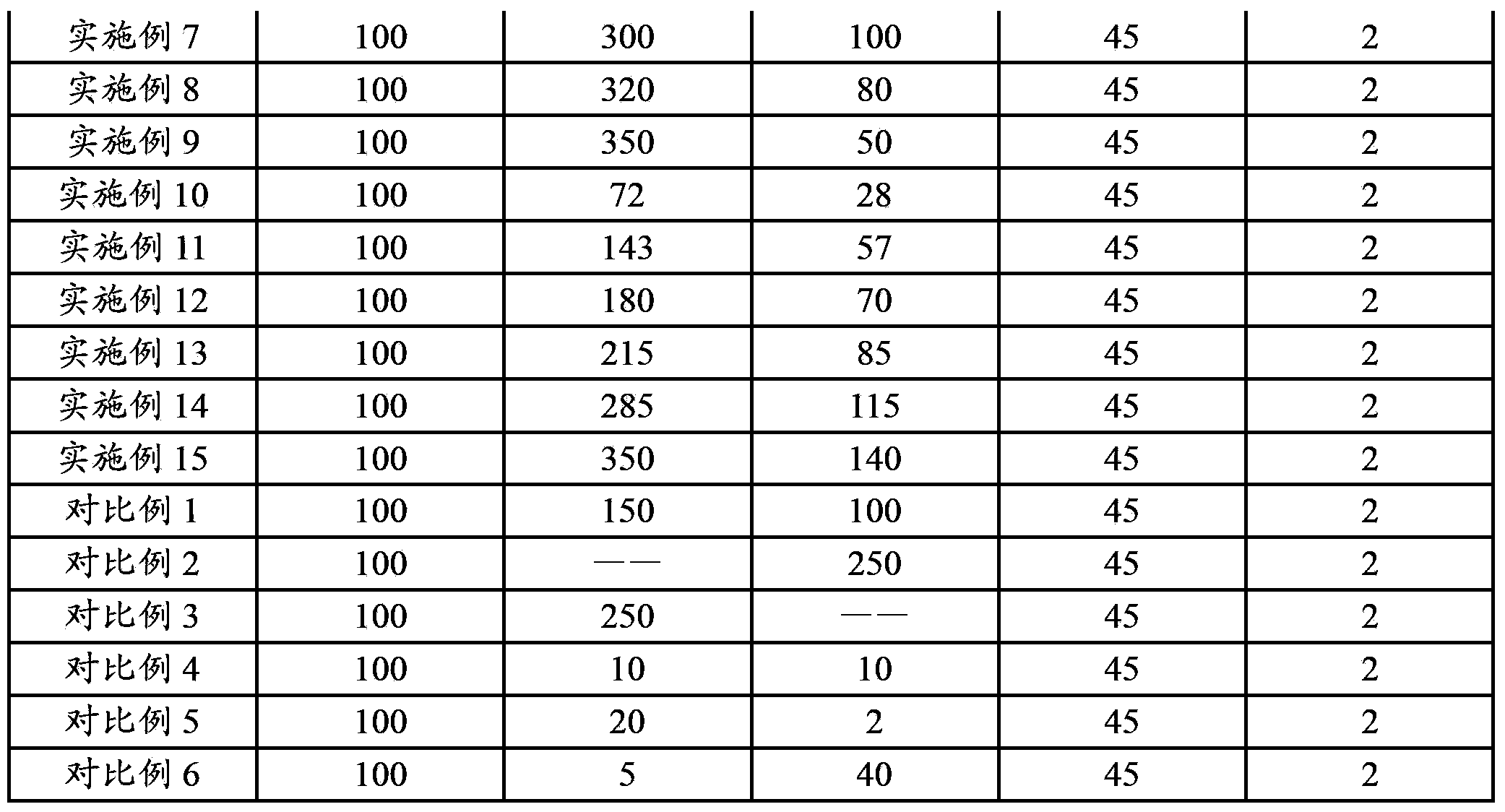

Embodiment 2~15

[0071] The preparation method is the same as that of Example 1, the only difference being that the components and dosage are different, please refer to Table 1 for details.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap