Method for Selective Desulfurization of Synthetic Raw Gas

A selective, scrubbing technology used in separation methods, chemical instruments and methods, removal of gaseous pollutants, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

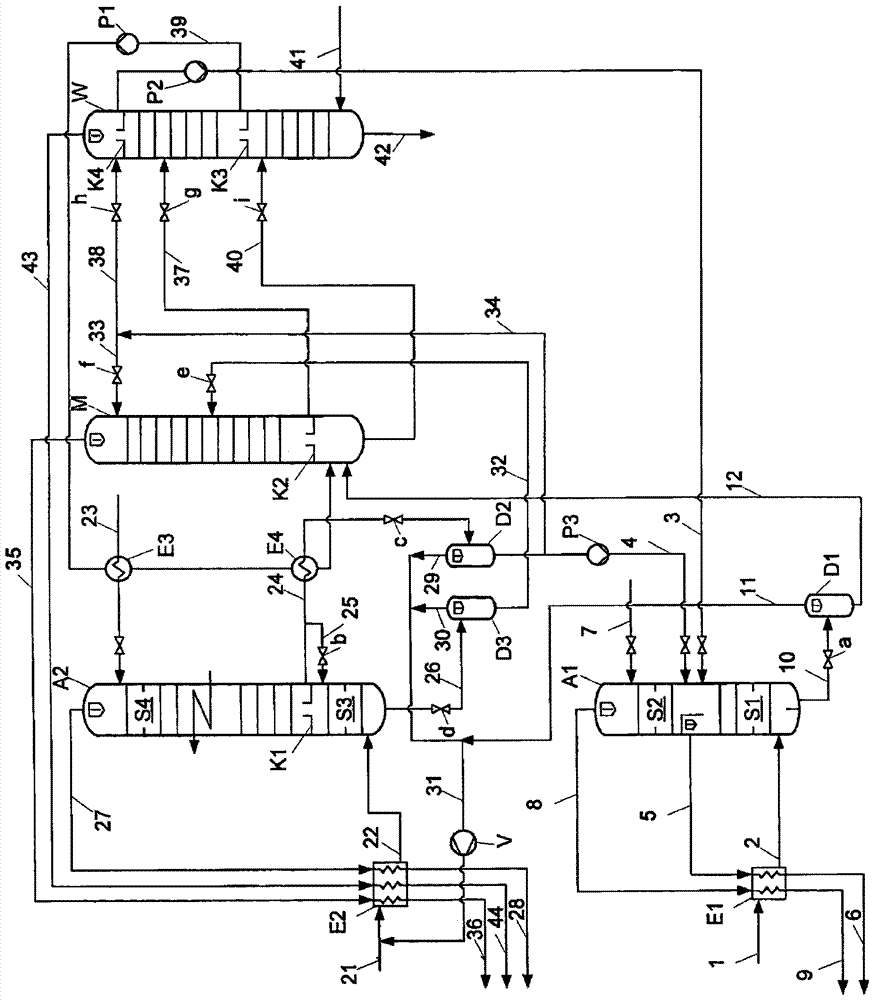

[0017] In order to obtain fuel for the gas turbine, unconverted raw synthesis gas 1 containing, in addition to hydrogen and carbon monoxide, also carbon dioxide and sulfur components is led into the heat exchanger E1 and cooled there opposite the process stream to be heated, It can then be fed via line 2 into the lower region of the scrubber A1 designed as an absorption column. In the absorption column A1, which typically operates at a pressure between 20 and 80 bar and comprises a first scrubbing zone S1 and a second scrubbing zone S2, the cooled synthesis raw gas flows upwards and is here connected with the supply via lines 3 and 4 The methanol detergent to the upper end of the washing zone S1 comes into intense contact. The two sulfur-free methanol streams 3 and 4 are pre-loaded with carbon dioxide and enter scrubbing zone S1 at a higher partial pressure of carbon dioxide than the synthetic crude gas 2 to be scrubbed, so although the carbon dioxide partial pressure from the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com