Thermal field balancing device of sapphire crystal growing furnace

A technology of sapphire crystal and balancing device, applied in crystal growth, single crystal growth, single crystal growth and other directions, can solve the problems of large thermal stress, high dislocation density, high cost, and achieve the effect of stable crystal structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

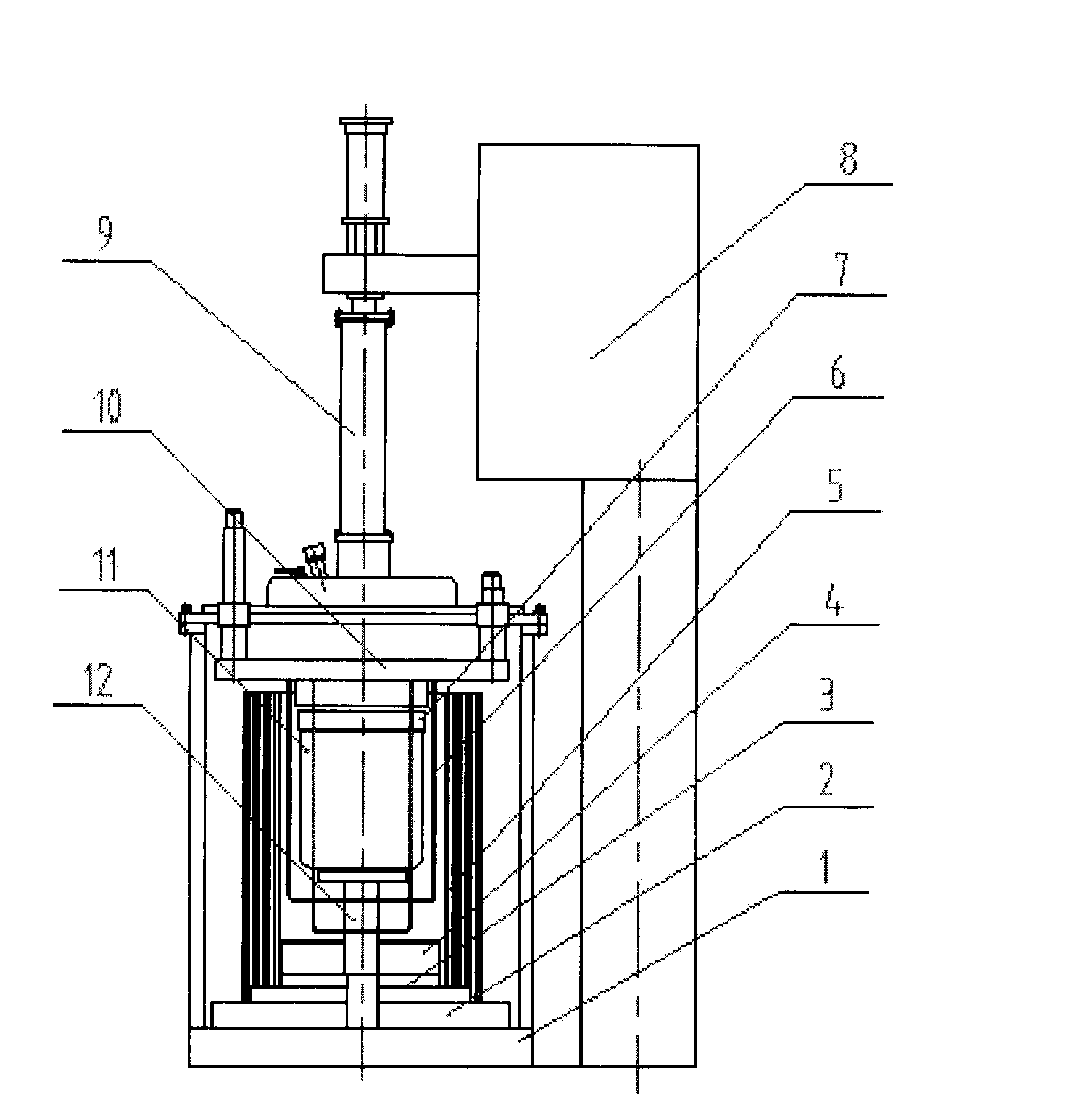

[0010] The technical scheme of the present invention is described in detail below in conjunction with the embodiment shown in the accompanying drawings:

[0011] figure 1 As shown, a sapphire crystal growth furnace temperature field balance device includes an upper reflective screen 7 installed on the top of the sapphire crystal growth furnace furnace body 1, a side reflective screen 5 installed around the sapphire crystal growth furnace furnace body 1, and a sapphire crystal growth furnace body. The lower reflection screen 4 at the bottom of the growth furnace body 1 .

[0012] When the present invention is in use, the corundum pad 2 is installed based on the central position of the furnace body 1, the side reflective screen 5 is installed on the corundum pad 2, and the fixed plate 3, the lower reflective screen 4, The heating element 6 is connected to the electrode 10 . The tungsten rod 12 is firmly connected with the fixed plate 3 , and the crucible 11 is placed on the tu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com