Low-bias-weft-skew knitted fabric

A knitted fabric and weft skew technology, applied in the field of knitted fabrics, can solve the problems of waste of triangular fabrics, increase in production cost, etc., and achieve the effects of avoiding coil skew, reducing torque, and simple weaving process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] Using different colors of cotton false-twist low-torque yarns as raw materials, the twist coefficient is 230-270, after loosening tube → dyeing yarn → drying → tightening tube → weaving → bleaching and dyeing → finishing steps to process colored striped jersey.

[0018] The weaving process adopts single jersey weft jersey on a single jersey circular knitting machine. The threading method is 1-32F through white cotton low-torque yarn, 33-48F through black cotton low-torque yarn, weaving density 300mm / 100 needles, the yarn tension is 10-12g.

[0019] The loom adopts German Meyer MV4-3.2Ⅱ single jersey circular knitting machine, the machine size is 24 needles / 25.4mm, the cylinder diameter is 30", the total number of needles is 2256, and the number of routes is 96F.

[0020] After weaving, the fabric is dyed, washed, and stented at low temperature.

Embodiment 2

[0022] Color striped jersey under the same weaving condition with ordinary yarn count

[0023] Comparative example 1 and example 2 color striped jersey weft data:

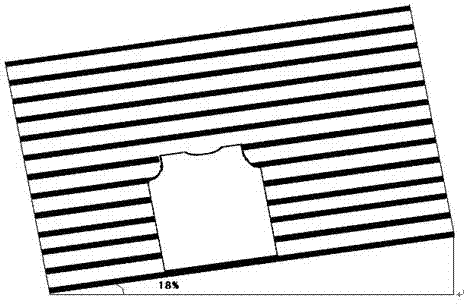

[0024] Such as figure 1 Shown, it is ordinary yarn-dyed color striped jersey with a weft slope of 18% and a large weft slope;

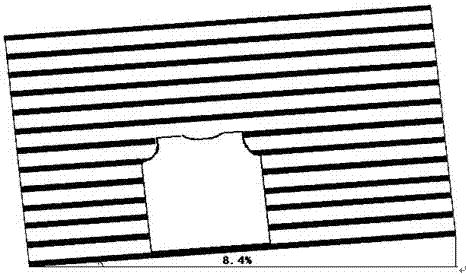

[0025] Such as figure 2 As shown, the low-torque yarn-dyed color striped jersey of the present invention has a weft slope of 8.4%. Compared with a jersey woven with ordinary yarn counts, the weft slope is significantly reduced, which improves the utilization rate of the fabric.

PUM

| Property | Measurement | Unit |

|---|---|---|

| twist factor | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com