Composite lithium-ion battery cell with low internal resistance, and preparation technology thereof

A composite lithium and ion battery technology, applied in sustainable manufacturing/processing, electrolyte battery manufacturing, circuits, etc., can solve the problems of high battery internal resistance, rising product defect rate, poor heat dissipation, etc., to reduce battery internal resistance, The effect of improving rate performance and reducing heat generation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

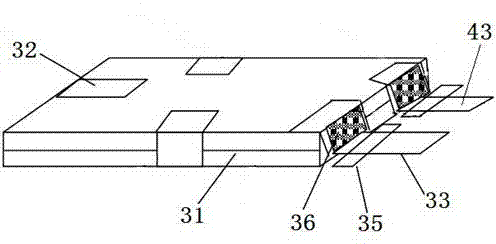

[0059] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings, taking a cell with a single cell of 5Ah and double cells connected in parallel with a cell of 10Ah as an example.

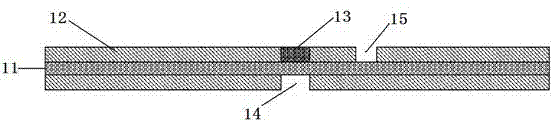

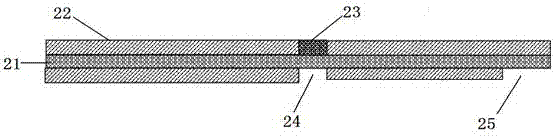

[0060] Such as figure 1 As shown, a positive electrode sheet for a 5Ah lithium-ion battery core, which includes an electrode sheet strip 11 , a positive electrode active material 12 , and a tab 12 . A section of blank foil area 14 with a width of 12 mm not coated with active material 12 is provided in the middle of the pole strip 11 for welding the tabs 13 . The tab 13 has a width of 10mm and a thickness of 0.2mm, and the top end is not covered with tab glue 35 . The tab 13 is exposed by 20mm, and the front and back of the blank foil area 14 are pasted with polyester PET insulating tape with a thickness of 0.03mm. The length of the insulating tape is 2.5±0.5mm higher than the upper end of the pole strip 11. A section ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com