Preparation method of mango juice

A technology for clear juice and mango, applied in the field of mango clear juice and its preparation, can solve the problems of poor fruit flavor and loss of nutrients, and achieve the effects of short sterilization time, reduced energy consumption, and preservation of taste and texture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

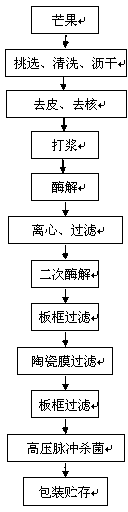

[0031] The production process of mango clear juice is as follows: figure 1 As shown, it specifically includes the following steps:

[0032] 1. Select mangoes with good color, full shape, high maturity and no rot, wash and drain, peel and remove the core, and cut into pieces;

[0033] 2. Pour 100kg of diced fruit into a cold beating machine for cold beating. The temperature of the entire cold beating process is controlled at -35°C to 25°C to make flocculent fruit puree;

[0034] 3. Add pectinase to the mango pulp prepared in step 2. The amount of pectinase added is 8g, and the enzymolysis is carried out at a temperature of 40°C for 1 hour to decompose the pectin substance;

[0035] 4. Pour the mango pulp obtained after enzymolysis in step 3 into a three-legged centrifuge for filtration to obtain the primary clear mango juice and mango pulp residue, and separate the juice residue to obtain the primary clear mango juice and mango pulp residue;

[0036] 5. Add pectinase to the p...

Embodiment 2

[0041] 1. Select mangoes with good color, full shape, high maturity and no rot, wash and drain, peel and remove the core, and cut into pieces;

[0042] 2. Pour 100kg of diced fruit into a cold beating machine for cold beating. The temperature of the entire cold beating process is controlled at -35°C to 25°C to make flocculent fruit puree;

[0043] 3. Add pectinase to the mango pulp made in step 2, the amount of pectinase added is 12g, enzymatically hydrolyze at a temperature of 50°C for 2h, and decompose the pectin substance;

[0044] 4. Pour the mango pulp obtained after enzymolysis in step 3 into a three-legged centrifuge for filtration to obtain the primary clear mango juice and mango pulp residue, and separate the juice residue to obtain the primary clear mango juice and mango pulp residue;

[0045] 5. Add pectinase to the primary clear mango juice obtained in step 4 for secondary enzymolysis. After enzymolysis, filter through a plate and frame filter to obtain secondary c...

Embodiment 3

[0050] 1. Select mangoes with good color, full shape, high maturity and no rot, wash and drain, peel and remove the core, and cut into pieces;

[0051] 2. Pour 100kg of diced fruit into a cold beating machine for cold beating. The temperature of the entire cold beating process is controlled at -35°C to 25°C to make flocculent fruit puree;

[0052] 3. Add pectinase to the mango pulp prepared in step 2. The amount of pectinase added is 10g, and the enzymolysis is carried out at a temperature of 50°C for 3h to decompose the pectin substance;

[0053] 4. Pour the mango pulp obtained after enzymolysis in step 3 into a three-legged centrifuge for filtration to obtain the primary clear mango juice and mango pulp residue, and separate the juice residue to obtain the primary clear mango juice and mango pulp residue;

[0054] 5. Add pectinase to the primary clear mango juice obtained in step 4 for secondary enzymolysis. After enzymolysis, filter through a plate and frame filter to obtai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com