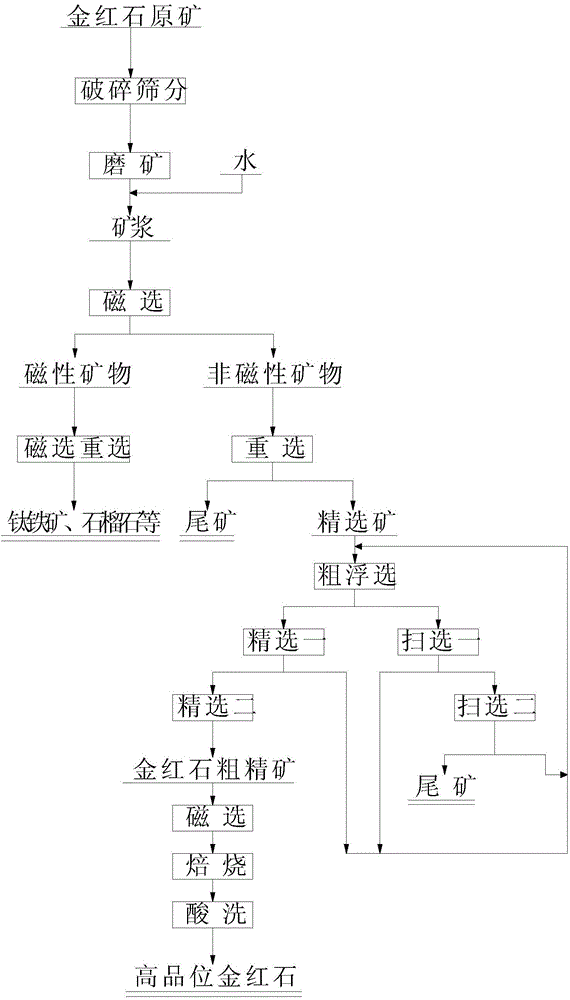

A rutile beneficiation method of magnetic separation, tailing, gravity separation, desliming and fine particle flotation

A beneficiation method and flotation technology, applied in the field of rutile beneficiation, can solve the problems of poor beneficiation effect, high cost, and low rutile recovery rate, and achieve the effect of reducing the amount of flotation and reducing the cost of beneficiation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] A rutile mine in Hubei is used as the raw rutile ore, which contains rutile TiO 22.24%. The main titanium-containing minerals in this ore are rutile, a small amount of ilmenite and titanite, other metal oxide minerals include a small amount to trace limonite, hematite and magnetite, and only trace pyrite in metal sulfide minerals; gangue minerals Mainly hornblende, followed by garnet, sodium mica, epidote, feldspar, chlorite, clay, quartz and so on. The particle size distribution range of rutile intercalation is wide, and the particle size is extremely uneven, mainly concentrated in 0.01-0.32mm. The intercalation relationship between rutile and gangue minerals is complex. Most rutiles are distributed in gangue minerals such as hornblende, garnet, and muscovite in the form of disseminated unequal grains and disseminated fine grains. The grain size of these rutiles is extremely uneven. , belongs to the primary refractory rutile mine in my country. The raw rutile ore is ...

Embodiment 2

[0029] The Zaoyang rutile ore is used as the raw rutile ore, which contains a large amount of magnetic minerals such as ilmenite, garnet and hornblende, and belongs to the primary refractory rutile mine in my country. The rutile raw ore is crushed and screened until the ore feeding particle size is 3mm, and the obtained rutile ore particles are ground to a particle size of 200 mesh with a grinding machine; the ground ore powder is prepared into a slurry with a concentration of 30%, and the The ore pulp is directly passed into the magnetic separator for magnetic separation, the magnetic field strength is 900T, and the magnetic separation can throw 27.66% of the tail; after magnetic separation, the magnetic minerals and non-magnetic minerals are obtained respectively, and the non-magnetic minerals are put into the spiral chute for gravity separation. Sludge, and carried out twice re-election, adding washing water 30ml / s in the first re-election, and without washing water in the s...

Embodiment 3

[0031] The Zaoyang rutile ore is used as the raw rutile ore, which contains a large amount of magnetic minerals such as ilmenite, garnet and hornblende, and belongs to the primary refractory rutile mine in my country. The rutile raw ore is crushed and screened until the ore feeding particle size is 3mm, and the obtained rutile ore particles are ground to a particle size of 200 mesh with a grinding machine; the ground ore powder is prepared into a slurry with a concentration of 30%, and the The ore pulp is directly passed into the magnetic separator for magnetic separation, the magnetic field strength is 700T, and the magnetic separation can throw 19.74% of the tail; after magnetic separation, the magnetic minerals and non-magnetic minerals are obtained respectively, and the non-magnetic minerals are put into the spiral chute for gravity separation. Sludge, and carried out twice re-election, adding washing water 30ml / s in the first re-election, and without washing water in the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com