One-step microwave preparation method for bimetal/carbon layered composite sphere

A technology of bimetal and composite balls, applied in the field of preparation of bimetal/carbon composite balls, can solve the problems of complicated steps and non-uniform products, and achieve the effects of good monodispersity, good controllability and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Preparation of palladium nanoparticles-doped carbon (Pd / C) composite spheres: Add 0.1 g of dry microporous carbon spheres to 50 mL of PdCl at a concentration of 2 mM at room temperature 2 solution for immersion. After soaking for 0.5h, add 0.05g polyvinylpyrrolidone and stir vigorously until completely dissolved. Then, the carbon sphere suspension was placed in a microwave reactor and reacted for 10 min under the condition of microwave power of 140W. After the reaction vessel was taken out, it was naturally cooled to room temperature in the air, washed repeatedly by centrifugation with deionized water and absolute ethanol, and finally dried in an oven or dried for more than 6 hours.

Embodiment 2

[0037] Change the K of the precursor to 2 mM 2 PdCl 4 Solution, other conditions are with embodiment 1.

Embodiment 3

[0039] Change the heating condition to 100° C. water bath for 6 hours, and the other conditions are the same as in Example 1.

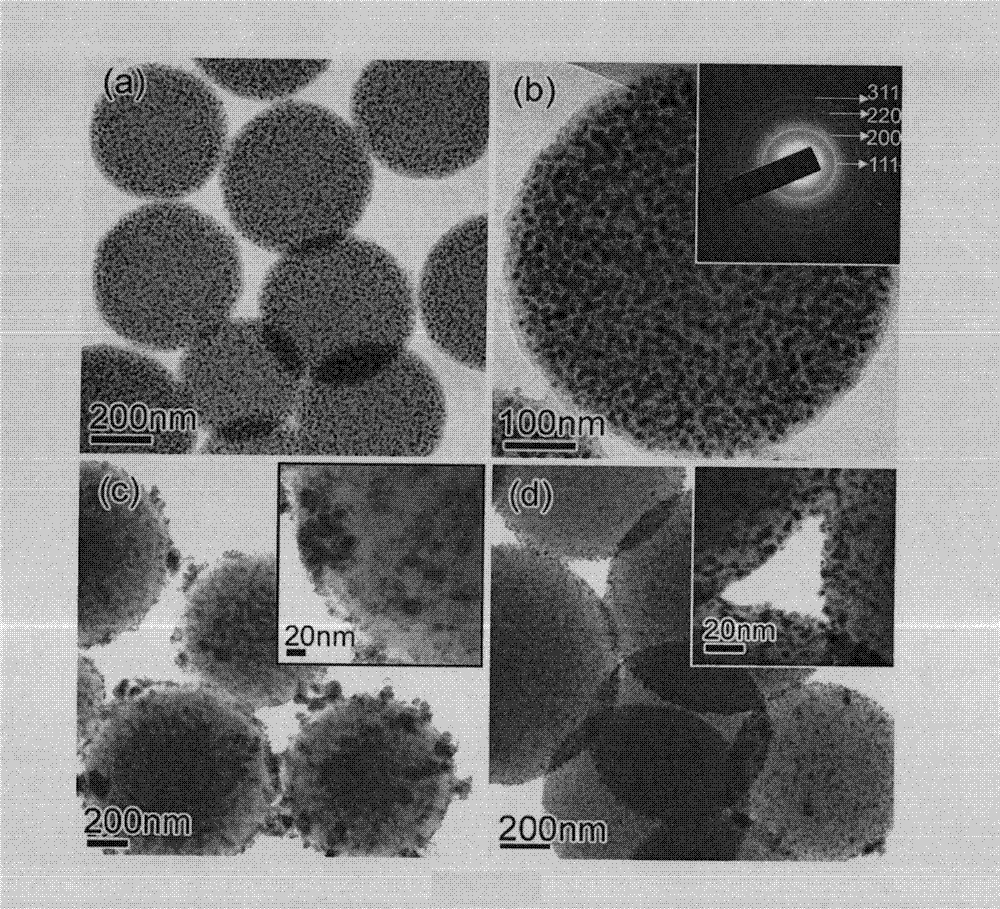

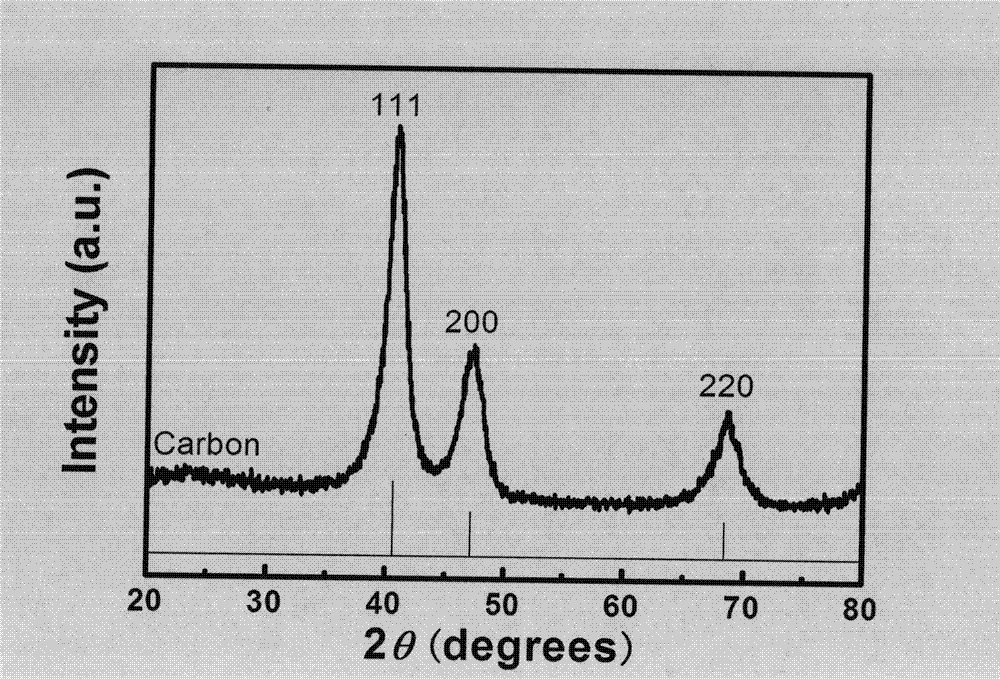

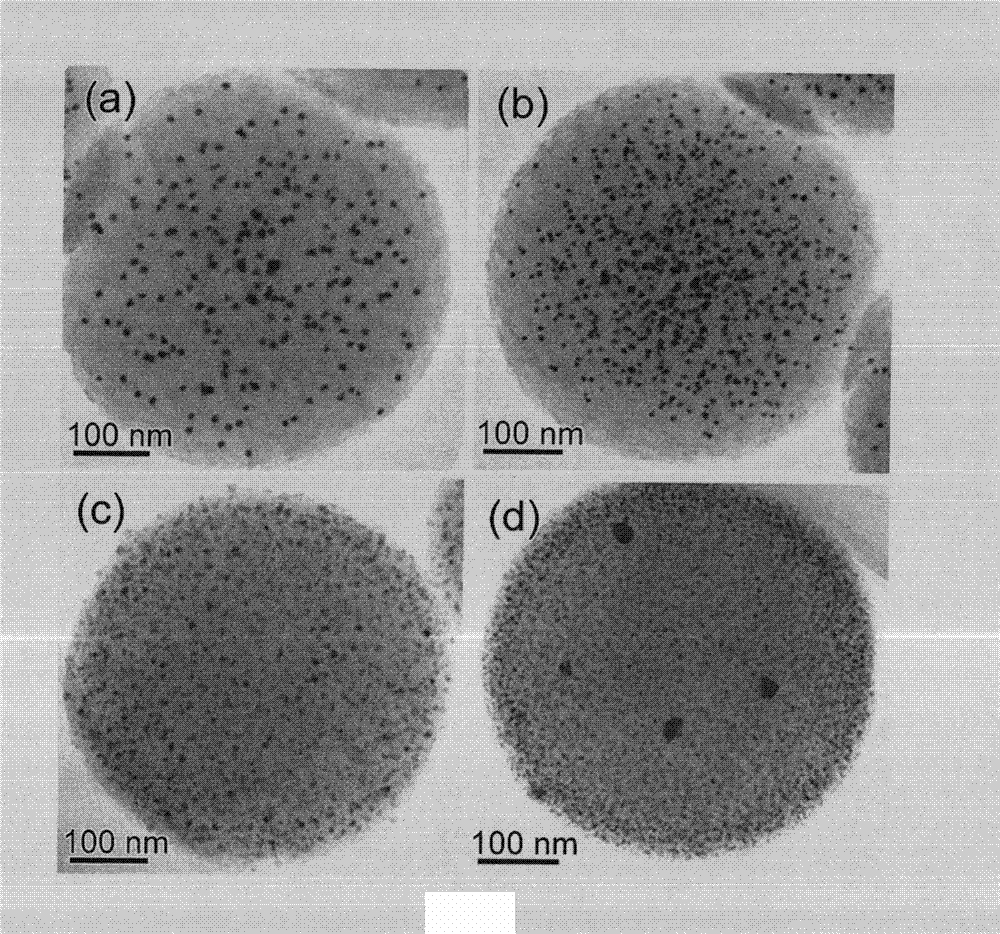

[0040] figure 1 It is the TEM picture of the product obtained when the same concentration, immersion time, microwave power and reaction time are used, but the palladium solution precursor is different. from figure 1 a It can be seen that the product obtained in Example 1 is a composite sphere uniformly doped with nanoparticles. TEM of a single composite sphere ( figure 1 b) shows that a large number of nanoparticles (8–10 nm in size) are located inside the carbon sphere, while there are almost no particles on the surface of the sphere. The SEM image (figure omitted) also confirms that there are no nanoparticles on the surface of the carbon spheres. The number density of nanoparticles in the area close to the surface of the sphere is higher than that in the central area, indicating that they are distributed in a spherical shell with a certain thick...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com