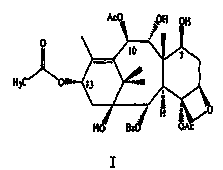

13-acetyl-9-dihydrobaccatin III extraction separation method

A separation method, acetyl technology, applied in the direction of organic chemistry, etc., to achieve remarkable separation effect, simple process, and reduce the difficulty of purification treatment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0014] Example 1: Take 1000g of dried Canadian branches and leaves, crush them to a particle size of 10-20 mesh, add 5L of methanol-water solution (70% concentration by mass) and soak for 12 hours before filtering, the filtrate is to be concentrated, and the filter residue is added with 3L of methanol water solution again After soaking for 20 hours, the filtrate was to be concentrated, and the filter residue was added to 3L methanol aqueous solution to soak for 10 hours and then filtered, and the filtrate obtained by filtering was combined three times. Extract with 1L chloroform, repeat the extraction 3 times, collect and combine the chloroform layers, and concentrate the chloroform layers to dryness to obtain 50 g of chloroform extract; after the chloroform extract is dissolved in acetone, add it to a Chroma-R204 resin (400 mesh) column, and pressurize The acetone-water solution with a mass percentage concentration of 40%, 50%, and 90% is eluted sequentially at a flow rate of ...

Embodiment 2

[0015] Example 2: Take 1000g of dried Canadian branches and leaves, crush them to 10 mesh, add 7L of methanol (40% by mass concentration) to soak for 24 hours and then filter, the filtrate is to be concentrated, and the filter residue is continued to be soaked in 4L of methanol for 24 hours, and the filtrate is to be concentrated. Add 4L of methanol to the filter residue and soak for 24 hours, then filter, combine and filter the obtained filtrate for three times, concentrate the filtrate to recover methanol, add hydrochloric acid solution with a concentration of 10% by mass to adjust the pH value of the filtrate to 6, then add 1L of chloroform to extract 4 times, collect and combine the chloroform layer, and the chloroform phase was concentrated to dryness to obtain 60g chloroform extract, which was dissolved in acetone and then added to the Chroma-R204 resin (500 mesh) column, with a pressurized mass percentage concentration of 40%, 50%, and 90%. The methanol-water solution wa...

Embodiment 3

[0016] Example 3: Take 1000g of dried Canadian branches and leaves, grind them to 20 mesh, add 4L of methanol (90% concentration by mass) to soak for 8 hours and then filter, the filtrate will be concentrated, and the filter residue will continue to be soaked in 3.5L of methanol for 10 hours, repeat 3 times , combined four times to filter the obtained filtrate, after the filtrate was concentrated and recovered methanol, adding a mass percent concentration of 10% hydrochloric acid solution to adjust the pH value of the filtrate to 5.5, then adding 2L chloroform to extract 3 times, collecting and merging the chloroform layers, and concentrating the chloroform phase to dryness to obtain 57g chloroform extract, after the chloroform extract is dissolved with acetone, join in the Chroma-R204 resin (400 order) column, be the ethanol-water solution of 40%, 50%, 90% with pressurized mass percentage concentration according to hour 2 The flow rate of the column volume is eluted sequential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com