Novel insulating paint for electrical parts and preparation method thereof

A technology of electrical parts and insulating varnish, applied in the direction of coating, etc., can solve problems such as improper preparation of materials, poor three-proof ability, and low adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

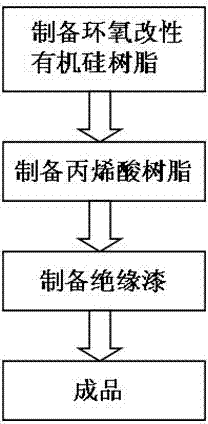

[0017] figure 1 It is a process step chart of the preparation method of the new insulating varnish for electrical parts in the embodiment of the present invention; the insulating varnish contains the following components by weight: 66% epoxy modified silicone resin, 22% acrylic resin, 2.5% pigment, Mica powder filler 8%, additive 1.5%.

[0018] The new insulating varnish for electrical parts mentioned in the present invention adopts self-made epoxy-modified silicone resin as the main film-forming material, uses acrylic resin as auxiliary resin, and then adds high-temperature-resistant pigments, functional fillers, and auxiliary agents to obtain energy-efficient varnishes. Drying at room temperature, the mechanical properties, medium resistance and insulation properties are all better than the high temperature self-drying insulating varnish of conventional drying insulating varnish. Among them, the epoxy-modified silicone resin is formed by the reaction of epoxy resin, butyl a...

Embodiment

[0021] The specific preparation method is as follows:

[0022] a) Preparation of epoxy-modified silicone resin, the specific preparation process is: first put 39% phenylchlorosilane, 20% methylchlorosilane, 11% toluene, and 30% butanol into a certain amount of water for hydrolysis, washing with water, Concentrate, add an appropriate amount of acetone solvent to dilute into a silanol intermediate with a solid content of 62%; then add epoxy resin and an appropriate amount of butyl acetate solvent into a four-necked bottle, heat up, and start stirring after the epoxy resin is dissolved, and stir evenly Finally, add silanol intermediates in batches at 40°C, the ratio of epoxy resin to silanol intermediates is 50:50, and finally condense to a certain viscosity and content at 160-190°C to obtain epoxy resin Modified silicone resin.

[0023] b) Preparation of acrylic resin, the specific preparation process is: first dissolve 40% acrylamide completely with 33% butanol, and let it sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com