Water cooling heat radiation system for electromagnetic heating device and control method of water cooling heat radiation system

An electromagnetic heating device, water-cooled heat dissipation technology, applied in induction heating control, coil device, induction heating and other directions, can solve problems such as difficulty in ensuring heat dissipation performance, affecting heat dissipation effect, poor heat conduction, etc., to save operating costs and energy consumption, saving Equipment investment, strong heat dissipation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

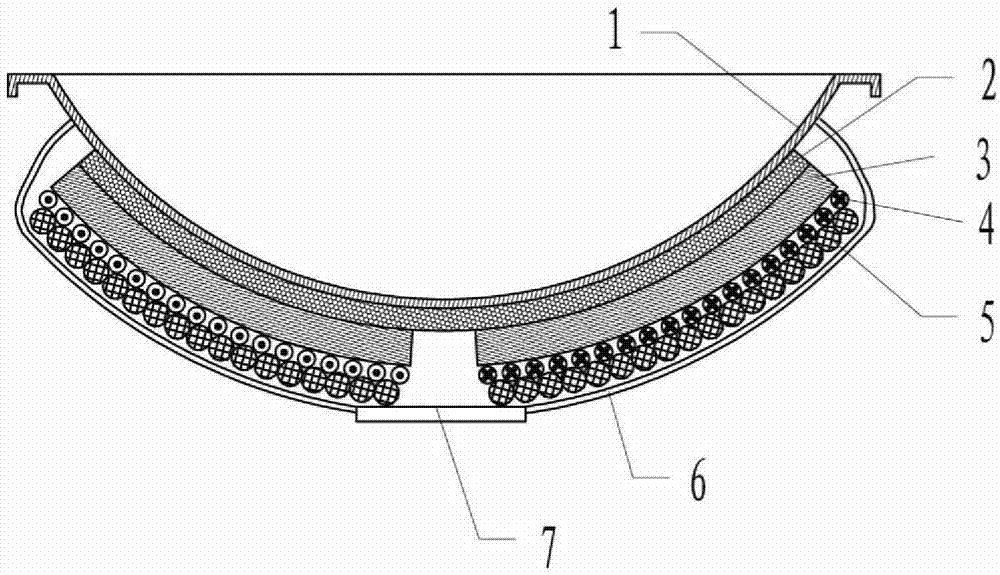

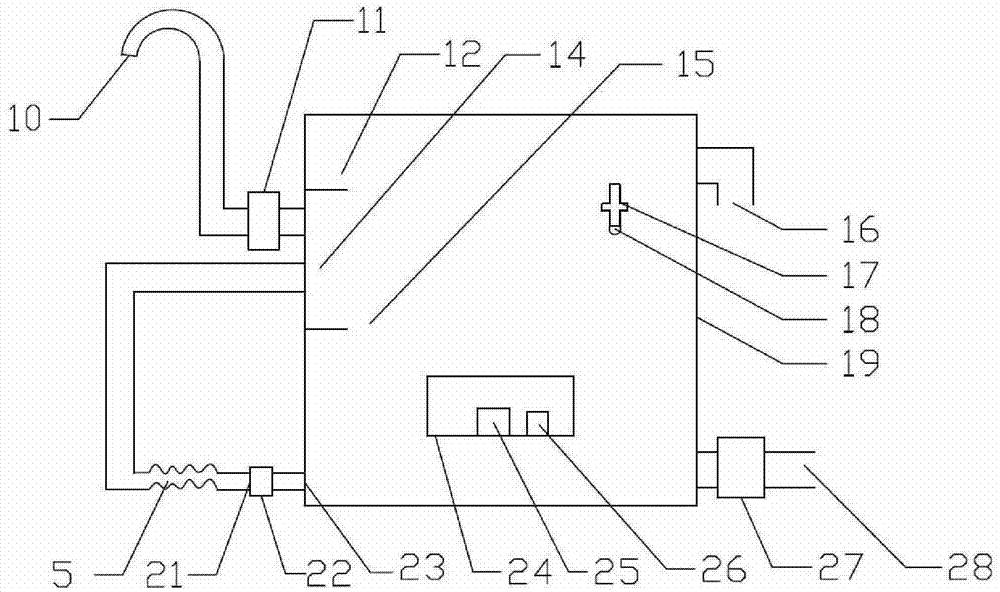

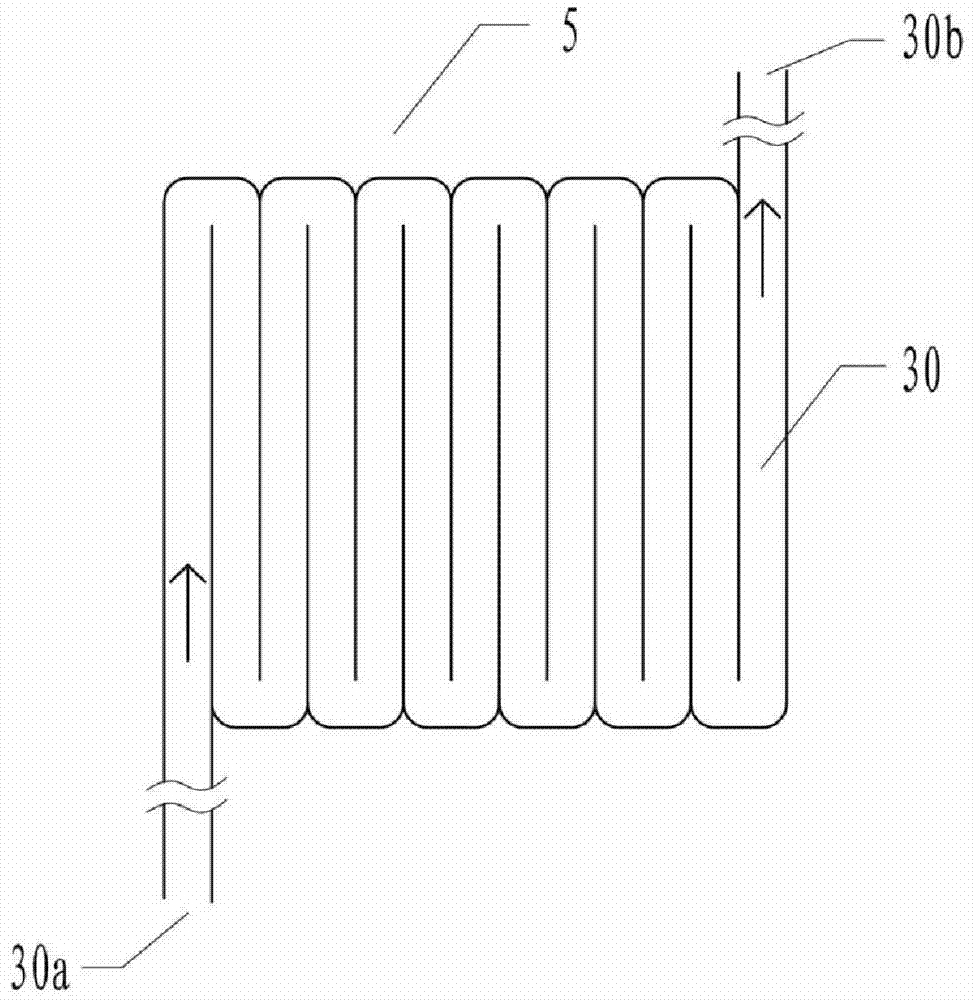

[0069] Such as figure 1 , 2 The water-cooling heat dissipation system of the electromagnetic heating device shown includes: an electromagnetic heating component 1, such as an electromagnetic cooker, an electromagnetic cooker, an electromagnetic cooker, and other industrial electromagnetic heating devices, which use the sympathetic magnetic force lines generated by the electromagnetic heating induction coil to form electromagnetic eddy currents to heat Substance, typically, it can be a U-shaped iron utensil.

[0070] The electromagnetic heating induction coil 4 is used to generate sympathetic magnetic force lines. The electromagnetic heating induction coil is wound by a coil and matched with the electromagnetic heating component 1, and is fixedly installed on the outer surface of the electroma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com