Preparation method for composite dried albumen

A compound protein and protein powder technology, which is applied in the field of compound protein dry preparation, can solve problems affecting product texture and shelf life, affecting industrial production efficiency, energy and time waste, etc., to achieve uniform and stable products, promote development, and full flexibility Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

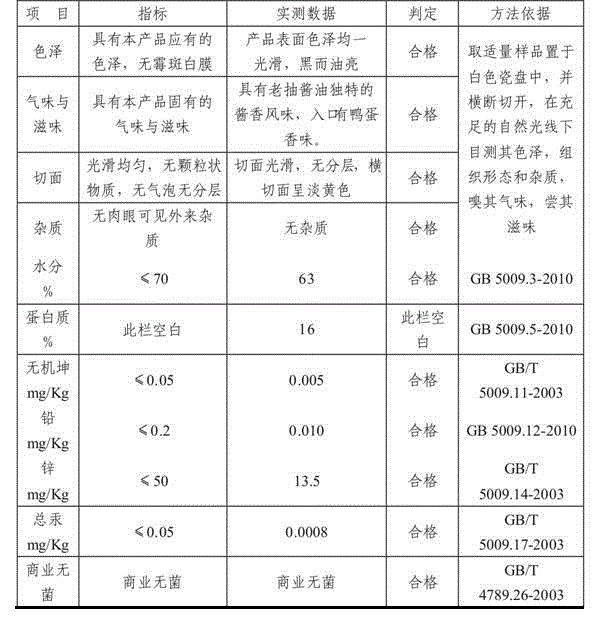

Embodiment 1

[0063] Preparation of egg soy protein dry:

[0064] (1) Raw material formula

[0065] Egg whole egg liquid 50 parts

[0066] Soy protein isolate powder 5 servings

[0067] 30 parts of water

[0068] 3 parts spiced water

[0069] 3 parts light soy sauce

[0070] 1 part white sugar

[0071] MSG 1 part

[0072] CMC-Na 0.18 parts.

[0073] (2) Spice water formula

[0074] 1200 parts of water

[0075] Cinnamon 5 parts

[0076] star anise 4 servings

[0077] Ginger 10 parts

[0078] 4 servings of black tea leaves

[0079] Cumin 4 parts

[0080] Fragrant leaves 4 parts

[0081] Cao Guo 4 servings

[0082] (3) Brine water formula

[0083] 100 parts of water

[0084] Dark soy sauce 10 parts.

[0085] Prepare according to the following process steps and process parameters:

[0086] (1) Spice water preparation: weigh 5 parts of cinnamon bark, 4 parts of star anise, 10 parts of ginger, 4 parts of black tea leaves, 4 parts of fennel, 4 parts of fragrant leaves, 4 parts o...

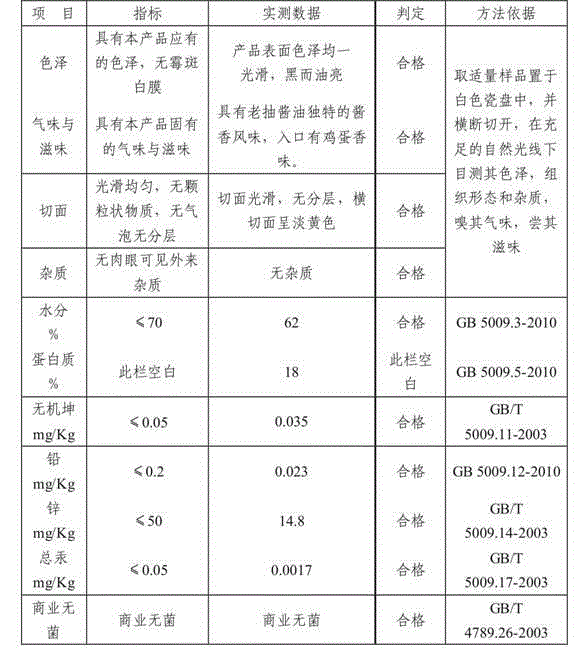

Embodiment 2

[0099] Preparation of dried duck egg soybean protein

[0100] (1) Raw material formula

[0101] Duck whole egg liquid 60 parts

[0102] Soy protein isolate powder 3 servings

[0103] 20 parts of water

[0104] Spice water 5 parts

[0105] 5 parts light soy sauce

[0106] 2 parts white sugar

[0107] MSG 2 parts

[0108] CMC-Na 0.5 parts

[0109] (2) Spice water formula

[0110] 1000 parts of water

[0111] Cinnamon 7 parts

[0112] star anise 4 servings

[0113] Ginger 20 parts

[0114] 5 servings of black tea leaves

[0115] Cumin 5 parts

[0116] Fragrant leaves 5 parts

[0117] Cao Guo 5 servings

[0118] (3) Brine water formula

[0119] 100 parts of water

[0120] Dark soy sauce 18 parts

[0121] Prepare according to the following process steps and process parameters:

[0122] (1) The preparation method of spice water is the same as in Example 1;

[0123] (2) Mix 3 parts of isolated soybean protein powder, 2 parts of white sugar, 0.5 parts of CMC-Na, a...

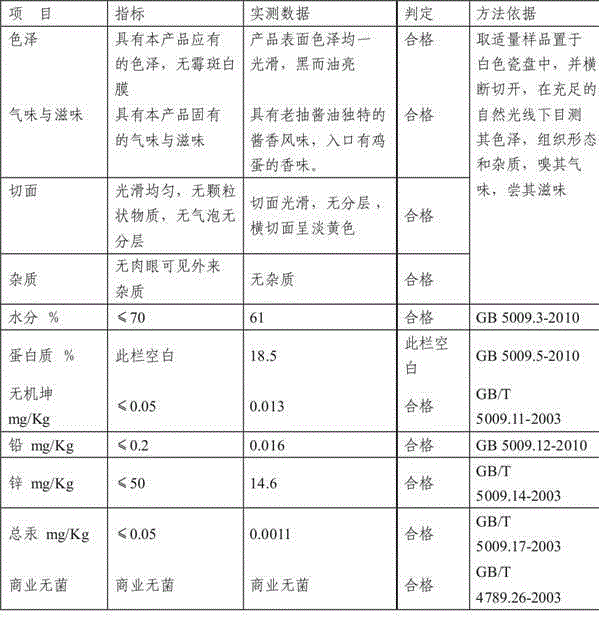

Embodiment 3

[0135] Preparation of dried egg and pea protein

[0136] (1) Raw material formula

[0137] Egg whole egg liquid 50 parts

[0138] Pea protein isolate powder 4 servings

[0139] 25 parts of water

[0140] 3 parts spiced water

[0141]3 parts light soy sauce

[0142] 1 part white sugar

[0143] MSG 2 parts

[0144] CMC-Na 0.2 parts

[0145] (2) Spice water formula

[0146] 1200 parts of water

[0147] Cinnamon 5 parts

[0148] star anise 5 servings

[0149] Ginger 15 parts

[0150] 4 servings of black tea leaves

[0151] Cumin 5 parts

[0152] Fragrant leaves 4 parts

[0153] Cao Guo 4 servings

[0154] (3) Brine water formula

[0155] 100 parts of water

[0156] Dark soy sauce 15 parts

[0157] Prepare according to the following process steps and process parameters:

[0158] (1) The preparation method of spice water is the same as in Example 1;

[0159] (2) Mix 4 parts of soybean protein isolate powder, 1 part of white sugar, 0.2 parts of CMC-Na, and 2 parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com